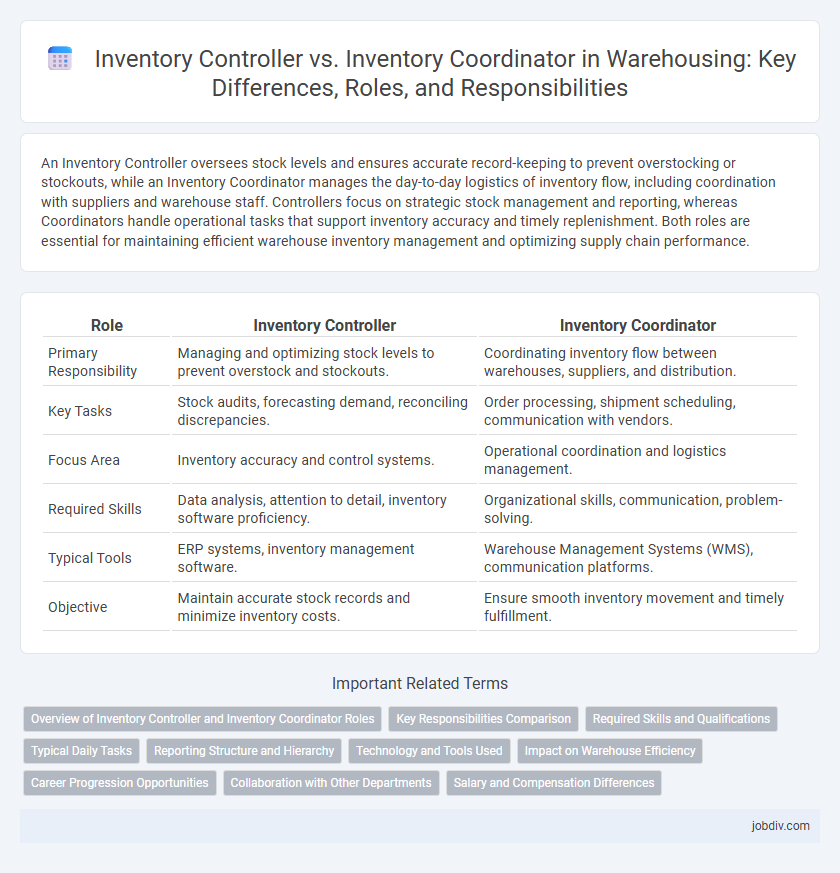

An Inventory Controller oversees stock levels and ensures accurate record-keeping to prevent overstocking or stockouts, while an Inventory Coordinator manages the day-to-day logistics of inventory flow, including coordination with suppliers and warehouse staff. Controllers focus on strategic stock management and reporting, whereas Coordinators handle operational tasks that support inventory accuracy and timely replenishment. Both roles are essential for maintaining efficient warehouse inventory management and optimizing supply chain performance.

Table of Comparison

| Role | Inventory Controller | Inventory Coordinator |

|---|---|---|

| Primary Responsibility | Managing and optimizing stock levels to prevent overstock and stockouts. | Coordinating inventory flow between warehouses, suppliers, and distribution. |

| Key Tasks | Stock audits, forecasting demand, reconciling discrepancies. | Order processing, shipment scheduling, communication with vendors. |

| Focus Area | Inventory accuracy and control systems. | Operational coordination and logistics management. |

| Required Skills | Data analysis, attention to detail, inventory software proficiency. | Organizational skills, communication, problem-solving. |

| Typical Tools | ERP systems, inventory management software. | Warehouse Management Systems (WMS), communication platforms. |

| Objective | Maintain accurate stock records and minimize inventory costs. | Ensure smooth inventory movement and timely fulfillment. |

Overview of Inventory Controller and Inventory Coordinator Roles

Inventory Controllers manage stock levels by monitoring inventory accuracy, tracking shipments, and reconciling discrepancies to ensure optimal warehouse operations. Inventory Coordinators oversee the logistical aspects of inventory flow, coordinating receipt, storage, and dispatch of goods while maintaining communication between suppliers, warehouse staff, and distribution teams. Both roles are crucial for inventory accuracy and efficient supply chain management, with Controllers emphasizing control and analysis and Coordinators focusing on coordination and execution.

Key Responsibilities Comparison

An Inventory Controller primarily manages stock accuracy, oversees inventory audits, and enforces warehouse compliance protocols to prevent discrepancies and optimize stock levels. An Inventory Coordinator focuses on coordinating daily inventory operations, facilitating communication between suppliers and warehouse staff, and ensuring timely stock replenishment to meet demand schedules. Both roles are crucial for maintaining effective inventory management, but the Controller emphasizes control and accuracy, while the Coordinator emphasizes operational flow and coordination.

Required Skills and Qualifications

Inventory Controllers require strong analytical skills, proficiency in inventory management software, and expertise in data analysis to maintain accurate stock levels and forecast demand. Inventory Coordinators need excellent organizational abilities, effective communication skills, and knowledge of supply chain processes to coordinate inventory flow between departments. Both roles benefit from attention to detail, experience with ERP systems, and a solid understanding of logistics and warehouse operations.

Typical Daily Tasks

Inventory Controllers typically focus on monitoring stock levels, conducting regular audits, and analyzing inventory reports to prevent discrepancies and ensure accuracy. Inventory Coordinators manage the flow of goods, coordinate with suppliers and logistics teams, and oversee order processing to maintain efficient warehouse operations. Both roles require strong attention to detail, but Controllers emphasize data analysis while Coordinators prioritize communication and coordination.

Reporting Structure and Hierarchy

An Inventory Controller typically holds a higher position within the warehouse management hierarchy, overseeing inventory accuracy, stock levels, and reporting directly to senior management or warehouse operations managers. In contrast, an Inventory Coordinator operates under the Inventory Controller or warehouse supervisors, managing day-to-day inventory tracking, order processing, and maintaining accurate records while reporting to the Inventory Controller or team leads. The reporting structure emphasizes the Inventory Controller's strategic role in decision-making and inventory audits, with the Inventory Coordinator handling operational tasks within that framework.

Technology and Tools Used

Inventory Controllers primarily utilize advanced inventory management software such as SAP, Oracle, and Microsoft Dynamics to monitor stock levels, perform audits, and ensure data accuracy, leveraging barcode scanners and RFID technology for real-time tracking. Inventory Coordinators often use warehouse management systems (WMS) like Fishbowl or NetSuite to coordinate inventory movements, schedule replenishments, and facilitate communication across supply chain teams. Both roles rely on data analytics tools and handheld devices to optimize inventory accuracy and operational efficiency within warehousing environments.

Impact on Warehouse Efficiency

An Inventory Controller ensures accurate stock levels by implementing rigorous tracking systems and conducting regular audits, which minimizes discrepancies and reduces stockouts. An Inventory Coordinator facilitates the flow of goods by coordinating with suppliers and warehouse teams, streamlining order fulfillment and enhancing communication. Together, their roles optimize warehouse efficiency by balancing stock accuracy and operational workflow management.

Career Progression Opportunities

Inventory Controllers typically manage stock accuracy and oversee inventory audits, providing a foundation for advancement into Supply Chain Manager or Warehouse Operations Manager roles. Inventory Coordinators focus on logistical support and order processing, positioning themselves for progression into Inventory Planner or Procurement Specialist careers. Both roles offer critical experience, but Inventory Controllers often have clearer pathways to senior management due to their strategic responsibility for inventory integrity.

Collaboration with Other Departments

Inventory Controllers and Inventory Coordinators collaborate closely with departments such as procurement, sales, and logistics to ensure accurate stock levels and timely replenishment. The Inventory Controller typically focuses on analyzing inventory data to forecast demand and prevent stockouts, while the Inventory Coordinator facilitates communication between warehouse staff and other departments to streamline order fulfillment and inventory tracking. Both roles are essential for maintaining efficient inventory flow and minimizing discrepancies across the supply chain.

Salary and Compensation Differences

Inventory Controllers typically earn higher salaries than Inventory Coordinators due to their advanced responsibilities in managing stock accuracy and financial reporting. In the United States, Inventory Controllers average a salary range between $55,000 and $75,000 annually, while Inventory Coordinators usually earn between $40,000 and $55,000. Compensation packages for Inventory Controllers often include performance bonuses and benefits tied to inventory optimization and cost-saving initiatives.

Inventory Controller vs Inventory Coordinator Infographic

jobdiv.com

jobdiv.com