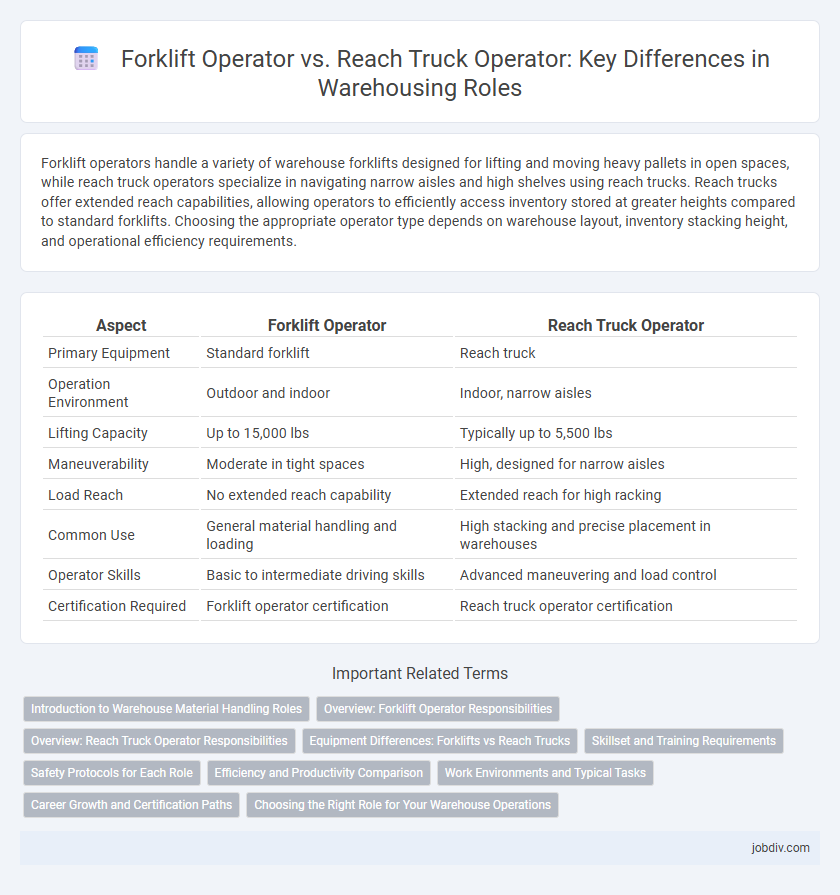

Forklift operators handle a variety of warehouse forklifts designed for lifting and moving heavy pallets in open spaces, while reach truck operators specialize in navigating narrow aisles and high shelves using reach trucks. Reach trucks offer extended reach capabilities, allowing operators to efficiently access inventory stored at greater heights compared to standard forklifts. Choosing the appropriate operator type depends on warehouse layout, inventory stacking height, and operational efficiency requirements.

Table of Comparison

| Aspect | Forklift Operator | Reach Truck Operator |

|---|---|---|

| Primary Equipment | Standard forklift | Reach truck |

| Operation Environment | Outdoor and indoor | Indoor, narrow aisles |

| Lifting Capacity | Up to 15,000 lbs | Typically up to 5,500 lbs |

| Maneuverability | Moderate in tight spaces | High, designed for narrow aisles |

| Load Reach | No extended reach capability | Extended reach for high racking |

| Common Use | General material handling and loading | High stacking and precise placement in warehouses |

| Operator Skills | Basic to intermediate driving skills | Advanced maneuvering and load control |

| Certification Required | Forklift operator certification | Reach truck operator certification |

Introduction to Warehouse Material Handling Roles

Forklift operators and reach truck operators play essential roles in warehouse material handling, each specializing in maneuvering different types of equipment for efficient inventory movement. Forklift operators primarily handle bulkier loads and outdoor yard tasks, while reach truck operators focus on high-density storage areas with narrow aisles inside the warehouse. Understanding these distinct roles improves operational workflow and enhances safety standards in warehouse environments.

Overview: Forklift Operator Responsibilities

Forklift operators are responsible for safely loading, unloading, and moving materials within warehouses, ensuring efficient inventory management and timely order fulfillment. They must operate various types of forklifts, including counterbalance and pallet jacks, while adhering to strict safety protocols to prevent accidents and damage. Proficiency in maneuvering heavy loads in tight spaces and performing routine equipment inspections is essential to maintain productivity and warehouse safety standards.

Overview: Reach Truck Operator Responsibilities

Reach truck operators are responsible for maneuvering reach trucks to lift, move, and place materials in high racking systems within warehouses efficiently and safely. They must accurately load and unload goods at elevated heights, conduct routine equipment inspections, and adhere to strict safety protocols to prevent accidents. Proficiency with warehouse management systems (WMS) and spatial awareness in narrow aisles are critical for optimizing inventory storage and retrieval.

Equipment Differences: Forklifts vs Reach Trucks

Forklifts feature a robust design with solid forks extending forward, ideal for lifting heavy loads and transporting pallets across various warehouse terrains. Reach trucks utilize a telescoping mechanism that allows forks to extend forward, enabling operators to access narrow aisles and reach higher storage racks efficiently. The fundamental mechanical distinction lies in the reach truck's ability to retract its forks, improving maneuverability in tight spaces compared to the fixed fork position on traditional forklifts.

Skillset and Training Requirements

Forklift operators require comprehensive training in maneuvering standard forklifts, including load handling, safety protocols, and maintenance checks, emphasizing strength and precision in confined warehouse spaces. Reach truck operators need specialized skills to operate extendable forks at elevated heights, demanding advanced training in stability control, spatial awareness, and mastering narrow aisle navigation. Both roles necessitate certification, but reach truck operation typically involves additional instruction due to the complexity of vertical lifts and extended reach capabilities.

Safety Protocols for Each Role

Forklift operators must adhere to strict safety protocols including regular equipment inspections, wearing personal protective equipment such as hard hats and high-visibility vests, and maintaining clear communication with ground personnel to prevent accidents. Reach truck operators follow specialized safety measures like ensuring load stability at elevated heights, verifying overhead clearance in narrow aisles, and utilizing operator seat belts and alarms to enhance visibility and prevent tipping. Both roles require comprehensive training on maneuvering techniques, hazard recognition, and emergency procedures to minimize workplace incidents and ensure compliance with Occupational Safety and Health Administration (OSHA) standards.

Efficiency and Productivity Comparison

Forklift operators typically handle heavier loads and operate in more open spaces, making them suitable for diverse warehousing tasks, while reach truck operators excel in narrow aisles due to their extended reach and maneuverability, enhancing space utilization. Reach trucks generally improve picking efficiency in high-density storage environments by reducing travel time and increasing stacking height, directly impacting productivity metrics. Choosing the appropriate operator depends on warehouse layout and inventory characteristics, with reach trucks often leading to higher throughput in compact, multi-level racking systems.

Work Environments and Typical Tasks

Forklift operators primarily work in outdoor or large warehouse settings, handling heavy pallets and transporting goods across wide aisles, while reach truck operators operate in narrower warehouse aisles, specializing in stacking and retrieving loads at significant heights. Forklift tasks often include loading and unloading trucks, moving goods between storage areas, and organizing inventory on ground-level racks, whereas reach truck operators focus on precise load placement and retrieval on elevated multi-tier racks. Both roles require adept vehicle handling skills but differ in maneuverability and operational focus due to the distinct design of each machine and typical warehouse layout.

Career Growth and Certification Paths

Forklift operators and reach truck operators both play critical roles in warehousing, with certification paths varying by equipment type and regional regulations, often requiring OSHA or equivalent safety training. Career growth for forklift operators typically involves advancing to supervisory roles or specializing in various forklift technologies, while reach truck operators may progress into more technical positions such as warehouse logistics coordinators or equipment trainers due to their expertise in narrow aisle operations. Obtaining advanced certifications in forklift and reach truck operation enhances job security and opens opportunities in larger logistics companies or specialized warehouse environments.

Choosing the Right Role for Your Warehouse Operations

Selecting the ideal role between forklift operator and reach truck operator depends on your warehouse layout, inventory type, and operational needs. Forklift operators excel in handling heavy pallets and loading trucks, while reach truck operators are better suited for narrow aisles and high racking systems. Evaluating factors such as aisle width, load weight, and stacking height ensures optimized warehouse efficiency and safety.

Forklift Operator vs Reach Truck Operator Infographic

jobdiv.com

jobdiv.com