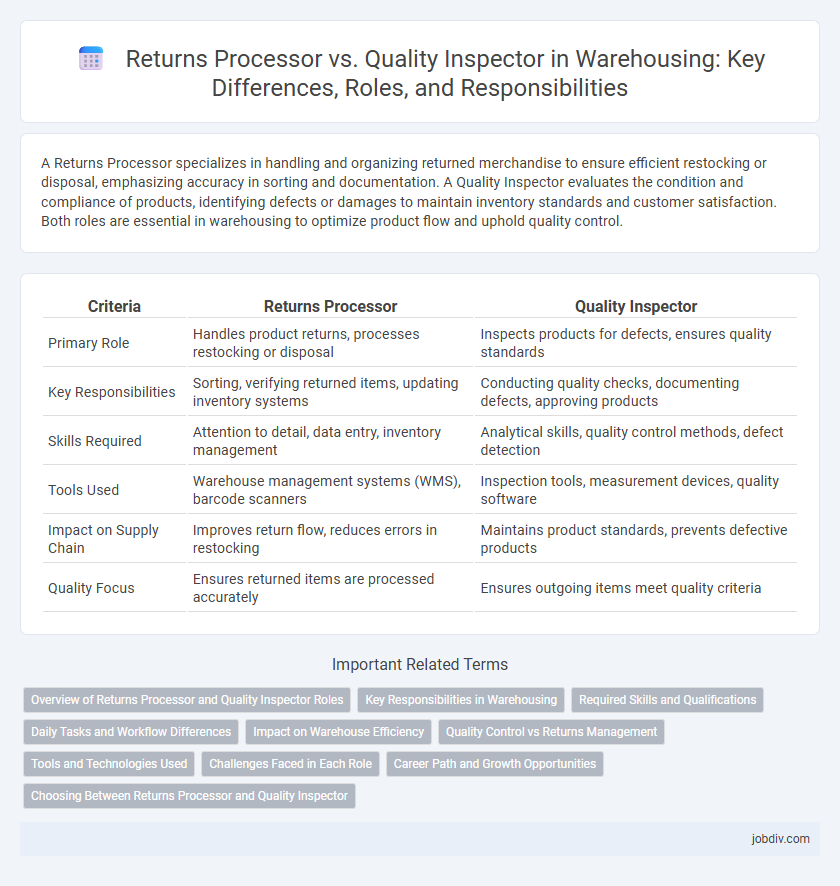

A Returns Processor specializes in handling and organizing returned merchandise to ensure efficient restocking or disposal, emphasizing accuracy in sorting and documentation. A Quality Inspector evaluates the condition and compliance of products, identifying defects or damages to maintain inventory standards and customer satisfaction. Both roles are essential in warehousing to optimize product flow and uphold quality control.

Table of Comparison

| Criteria | Returns Processor | Quality Inspector |

|---|---|---|

| Primary Role | Handles product returns, processes restocking or disposal | Inspects products for defects, ensures quality standards |

| Key Responsibilities | Sorting, verifying returned items, updating inventory systems | Conducting quality checks, documenting defects, approving products |

| Skills Required | Attention to detail, data entry, inventory management | Analytical skills, quality control methods, defect detection |

| Tools Used | Warehouse management systems (WMS), barcode scanners | Inspection tools, measurement devices, quality software |

| Impact on Supply Chain | Improves return flow, reduces errors in restocking | Maintains product standards, prevents defective products |

| Quality Focus | Ensures returned items are processed accurately | Ensures outgoing items meet quality criteria |

Overview of Returns Processor and Quality Inspector Roles

A Returns Processor manages the intake, inspection, and restocking of returned merchandise, ensuring items are accurately logged and processed for resale or disposal. A Quality Inspector evaluates products for defects or quality issues, maintaining compliance with standards and preventing subpar items from reaching customers. Both roles are critical in warehouse operations, optimizing inventory accuracy and upholding product quality control.

Key Responsibilities in Warehousing

A Returns Processor in warehousing manages the efficient intake, inspection, and sorting of returned goods to ensure accurate inventory updates and proper routing for restocking or disposal. A Quality Inspector focuses on verifying product specifications, detecting defects, and ensuring compliance with quality standards to maintain inventory integrity and customer satisfaction. Both roles are crucial for streamlining reverse logistics and sustaining operational efficiency within the warehouse environment.

Required Skills and Qualifications

Returns Processors require strong organizational skills, attention to detail, and proficiency in inventory management systems to efficiently process returned goods and update records. Quality Inspectors need expertise in quality control standards, defect identification, and familiarity with inspection tools to ensure products meet company and regulatory requirements. Both roles demand good communication abilities and a basic understanding of warehousing operations, but Quality Inspectors typically require more specialized training in quality assurance methodologies.

Daily Tasks and Workflow Differences

Returns Processors handle the intake, sorting, and documentation of returned products to ensure accurate restocking or disposal, focusing on efficient processing and updating inventory systems. Quality Inspectors conduct thorough examinations of incoming, in-process, or returned goods, identifying defects, verifying compliance with standards, and reporting issues to maintain product quality and safety. Workflow differences highlight that Returns Processors prioritize speed and accuracy in handling returns, while Quality Inspectors emphasize detailed analysis and quality control measures.

Impact on Warehouse Efficiency

Returns processors streamline warehouse operations by quickly sorting and categorizing returned items, reducing turnaround time and minimizing storage congestion. Quality inspectors ensure product standards are met by identifying defects early, which reduces the risk of shipping errors and costly returns. Balancing these roles enhances overall warehouse efficiency through improved workflow and inventory accuracy.

Quality Control vs Returns Management

Quality Inspectors play a crucial role in warehousing by ensuring product standards meet company and regulatory quality control requirements, identifying defects, and preventing faulty items from reaching customers. Returns Processors focus on returns management by efficiently handling incoming returned goods, verifying quantities, and updating inventory systems to maintain accurate stock records. Together, these roles balance maintaining product quality through inspections and managing the logistical flow of returned merchandise.

Tools and Technologies Used

Returns Processors utilize inventory management software, barcode scanners, and automated sorting systems to efficiently handle and categorize returned merchandise. Quality Inspectors rely on advanced inspection tools such as digital calipers, optical scanners, and quality management software to assess product integrity and compliance with industry standards. Both roles increasingly integrate AI-powered analytics and IoT sensors to enhance accuracy and streamline workflow in modern warehousing environments.

Challenges Faced in Each Role

Returns processors encounter challenges such as accurately sorting and categorizing returned items, managing high volumes of returns efficiently, and preventing inventory discrepancies. Quality inspectors face difficulties in detecting subtle defects, ensuring consistent product standards across batches, and balancing detailed inspections with production deadlines. Both roles require meticulous attention to detail but differ in focus, with returns processors emphasizing logistical accuracy and quality inspectors prioritizing product integrity.

Career Path and Growth Opportunities

Returns Processors typically begin their career managing the intake and sorting of returned merchandise, gaining foundational knowledge in inventory control and customer service protocols. Quality Inspectors progress by specializing in product evaluation standards, often advancing to supervisory roles or quality assurance management due to their expertise in identifying defects and ensuring compliance with industry regulations. Both career paths offer growth opportunities, with Returns Processors able to shift into logistics coordination and Quality Inspectors moving toward roles in operational efficiency and quality system development.

Choosing Between Returns Processor and Quality Inspector

Choosing between a Returns Processor and a Quality Inspector depends on the primary warehouse focus: Returns Processors specialize in efficiently handling and restocking returned goods to maintain inventory accuracy, while Quality Inspectors concentrate on identifying defects and ensuring products meet quality standards before reintegration. Warehouses prioritizing rapid processing of returns to minimize disruption benefit from Returns Processors, whereas those emphasizing product compliance and customer satisfaction rely on Quality Inspectors. Aligning the role with operational goals enhances inventory management, reduces errors, and supports overall supply chain effectiveness.

Returns Processor vs Quality Inspector Infographic

jobdiv.com

jobdiv.com