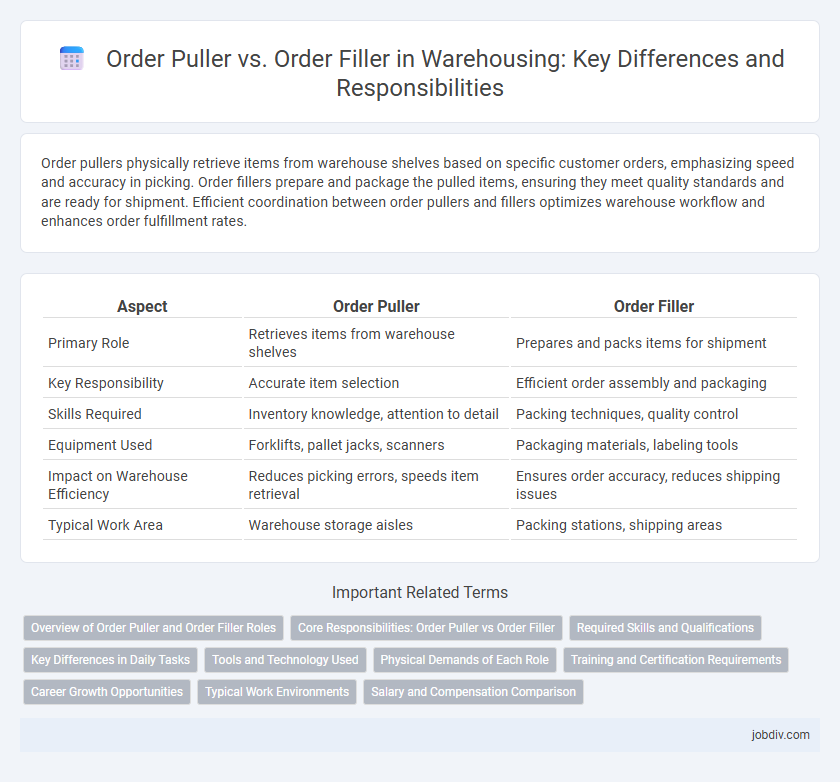

Order pullers physically retrieve items from warehouse shelves based on specific customer orders, emphasizing speed and accuracy in picking. Order fillers prepare and package the pulled items, ensuring they meet quality standards and are ready for shipment. Efficient coordination between order pullers and fillers optimizes warehouse workflow and enhances order fulfillment rates.

Table of Comparison

| Aspect | Order Puller | Order Filler |

|---|---|---|

| Primary Role | Retrieves items from warehouse shelves | Prepares and packs items for shipment |

| Key Responsibility | Accurate item selection | Efficient order assembly and packaging |

| Skills Required | Inventory knowledge, attention to detail | Packing techniques, quality control |

| Equipment Used | Forklifts, pallet jacks, scanners | Packaging materials, labeling tools |

| Impact on Warehouse Efficiency | Reduces picking errors, speeds item retrieval | Ensures order accuracy, reduces shipping issues |

| Typical Work Area | Warehouse storage aisles | Packing stations, shipping areas |

Overview of Order Puller and Order Filler Roles

Order pullers are responsible for retrieving products from warehouse shelves based on customer orders, ensuring accuracy and speed in picking items for shipment. Order fillers organize and prepare the picked items for packing, checking quantities and quality to confirm orders are complete and ready for dispatch. Both roles are critical in warehouse operations, supporting efficient order fulfillment and inventory management.

Core Responsibilities: Order Puller vs Order Filler

Order pullers are responsible for retrieving products from storage locations based on order specifications, ensuring accuracy and efficiency in picking items to fulfill customer orders. Order fillers focus on packaging, labeling, and preparing pulled items for shipment, verifying quantities and quality before dispatch. Both roles are critical in warehouse operations for maintaining order accuracy and timely delivery.

Required Skills and Qualifications

Order pullers require strong physical stamina, attention to detail, and proficiency in using warehouse management systems to locate and retrieve products efficiently. Order fillers need excellent organizational skills, accuracy in picking items according to specifications, and familiarity with inventory control software to ensure correct order assembly. Both roles demand basic math skills, the ability to follow safety protocols, and experience with forklifts or pallet jacks is often preferred.

Key Differences in Daily Tasks

Order pullers primarily focus on retrieving products from storage based on specific customer orders, often working with handheld scanners and RF devices to ensure accuracy. Order fillers concentrate on assembling and packaging items into shipping containers, verifying quantities and labels for shipment. Both roles require attention to detail but differ in their interaction with inventory movement and packaging processes.

Tools and Technology Used

Order pullers utilize handheld barcode scanners and mobile RF devices to locate and retrieve items efficiently, while order fillers often rely on conveyor systems and automated picking robots to assemble orders accurately. Warehouse management software (WMS) integrates with both roles, providing real-time inventory data, task prioritization, and tracking tools to enhance productivity. Voice-directed picking technology is increasingly common for both pullers and fillers, reducing errors and improving speed in order processing.

Physical Demands of Each Role

Order pullers in warehousing primarily engage in extensive walking, lifting, and manual handling of large, heavy items, requiring significant physical strength and stamina. Order fillers often perform repetitive picking and packing tasks that demand fine motor skills and prolonged standing, emphasizing speed and accuracy over heavy lifting. Both roles necessitate ergonomic awareness to minimize strain and injury during physically intensive activities.

Training and Certification Requirements

Order Pullers typically require hands-on training in inventory management systems and safety procedures, with certifications like OSHA Forklift Operator or Material Handling Safety preferred. Order Fillers need training on product identification, picking accuracy, and quality control, often supported by certifications such as Certified Logistics Associate (CLA) or Warehouse Safety Certification. Both roles benefit from ongoing professional development to improve efficiency and compliance with industry standards.

Career Growth Opportunities

Order Pullers typically begin their warehousing careers by efficiently retrieving products from inventory racks, gaining foundational experience in inventory management and spatial organization. Order Fillers, often advancing from order pulling roles, handle more complex tasks like assembling and packaging orders, which develop skills in accuracy, quality control, and workflow optimization, making them strong candidates for supervisory or logistics coordinator positions. Career growth in warehousing favors those who demonstrate proficiency in order accuracy and ergonomics, with opportunities to progress into inventory control specialists, warehouse supervisors, and operations managers.

Typical Work Environments

Order pullers typically operate in large distribution centers or retail warehouses where they navigate aisles to retrieve items based on pick lists, often requiring mobility and physical stamina. Order fillers usually work in more controlled environments such as cold storage facilities or pharmaceutical warehouses, focusing on accuracy and careful handling of products during order assembly. Both roles demand adherence to safety protocols but differ in spatial dynamics and operational conditions due to the nature of inventory and order processing tasks.

Salary and Compensation Comparison

Order Pullers in warehousing typically earn an average salary ranging from $28,000 to $35,000 annually, reflecting their role in physically retrieving items from inventory. Order Fillers, responsible for organizing and packing orders, generally receive slightly lower compensation, averaging between $25,000 and $32,000 per year. Salary variations depend on factors such as location, experience, and warehouse size, with some employers offering performance bonuses and overtime pay to both positions.

Order Puller vs Order Filler Infographic

jobdiv.com

jobdiv.com