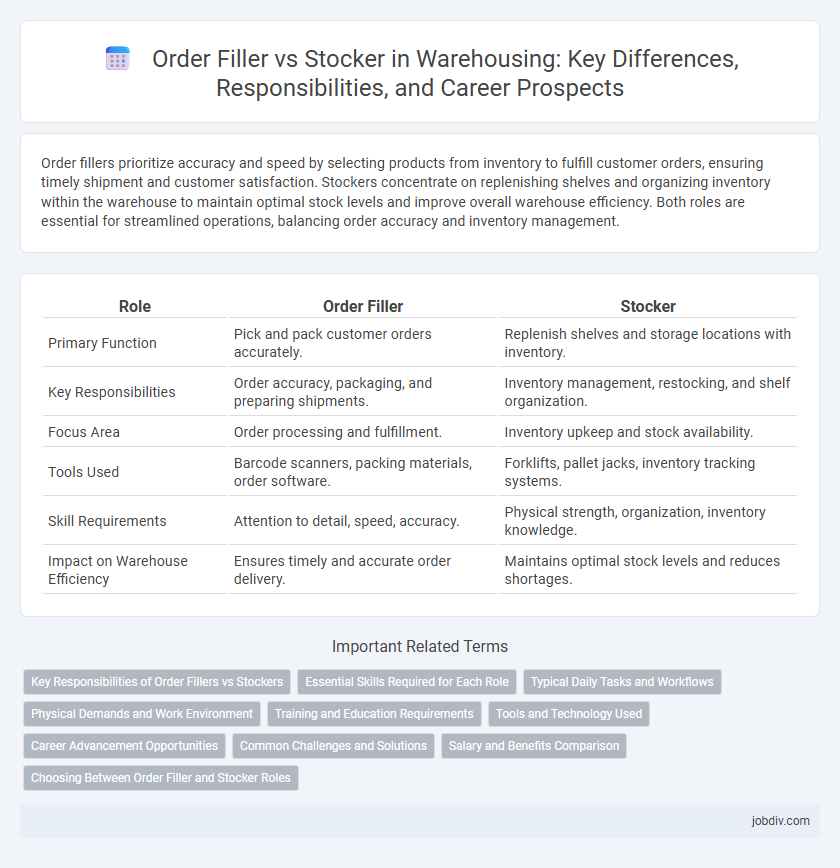

Order fillers prioritize accuracy and speed by selecting products from inventory to fulfill customer orders, ensuring timely shipment and customer satisfaction. Stockers concentrate on replenishing shelves and organizing inventory within the warehouse to maintain optimal stock levels and improve overall warehouse efficiency. Both roles are essential for streamlined operations, balancing order accuracy and inventory management.

Table of Comparison

| Role | Order Filler | Stocker |

|---|---|---|

| Primary Function | Pick and pack customer orders accurately. | Replenish shelves and storage locations with inventory. |

| Key Responsibilities | Order accuracy, packaging, and preparing shipments. | Inventory management, restocking, and shelf organization. |

| Focus Area | Order processing and fulfillment. | Inventory upkeep and stock availability. |

| Tools Used | Barcode scanners, packing materials, order software. | Forklifts, pallet jacks, inventory tracking systems. |

| Skill Requirements | Attention to detail, speed, accuracy. | Physical strength, organization, inventory knowledge. |

| Impact on Warehouse Efficiency | Ensures timely and accurate order delivery. | Maintains optimal stock levels and reduces shortages. |

Key Responsibilities of Order Fillers vs Stockers

Order fillers primarily focus on accurately selecting and packing products to fulfill customer orders, ensuring timely shipment and maintaining inventory accuracy. Stockers are responsible for receiving, organizing, and replenishing inventory on warehouse shelves, maintaining stock levels and warehouse cleanliness. Both roles are crucial for efficient warehouse operations, supporting order accuracy and inventory management.

Essential Skills Required for Each Role

Order fillers require strong attention to detail, speed, and accuracy in picking and packing items to meet precise customer orders. Stockers must possess organizational skills, physical stamina, and the ability to manage inventory effectively to ensure shelves are replenished and products are stored correctly. Both roles demand teamwork and familiarity with warehouse management systems for efficient operations.

Typical Daily Tasks and Workflows

Order fillers prioritize picking and packing customer orders accurately, often using handheld scanners to verify items and quantities before shipment. Stockers focus on replenishing shelves, organizing inventory, and maintaining warehouse layout efficiently to ensure easy access and minimize retrieval times. Both roles collaborate closely to streamline order fulfillment processes and maintain optimal inventory levels.

Physical Demands and Work Environment

Order fillers engage in repetitive lifting, bending, and standing for extended periods in climate-controlled warehouse settings, often handling small to medium-sized items with precision. Stockers perform more heavy lifting and physical labor, moving bulky goods and pallets, sometimes in less climate-regulated areas such as loading docks or storage yards. Both roles require strong physical stamina and attention to safety protocols due to the demanding nature of warehouse environments.

Training and Education Requirements

Order fillers require basic training focused on picking accuracy, inventory systems, and safety protocols, often supported by on-the-job experience. Stockers benefit from more extensive education in material handling equipment operation, inventory management software, and adherence to detailed stocking procedures. Both roles prioritize safety training, but stockers typically engage in additional certifications to handle heavy machinery and complex storage systems.

Tools and Technology Used

Order fillers primarily use handheld barcode scanners, mobile computers, and voice-directed picking systems to efficiently locate and verify items for shipment, ensuring accuracy and speed. Stockers rely on pallet jacks, forklifts, and inventory management software to replenish shelves and organize stock systematically, often integrating automated storage and retrieval systems (AS/RS) for enhanced efficiency. Both roles leverage warehouse management systems (WMS) to optimize workflow, track inventory in real-time, and maintain seamless operational coordination.

Career Advancement Opportunities

Order fillers gain valuable experience in inventory accuracy and picking efficiency, laying a strong foundation for roles such as inventory control specialist or warehouse supervisor. Stockers develop expertise in stock organization and replenishment techniques, which can lead to advanced positions like stock coordinator or logistics analyst. Both roles offer pathways to higher responsibilities within supply chain management, with advancement potential depending on skill development and certifications acquired.

Common Challenges and Solutions

Order fillers and stockers both face challenges such as inventory misplacement, inaccurate stock counts, and time management issues in warehousing operations. Implementing advanced warehouse management systems (WMS) and barcode scanning technology enhances accuracy and reduces errors for both roles. Regular training and cross-functional collaboration improve efficiency, ensuring order fillers and stockers adapt to dynamic inventory demands and optimize workflow.

Salary and Benefits Comparison

Order fillers typically earn a median hourly wage of $13 to $17, reflecting skills in efficient item picking and packing, while stockers average slightly lower wages around $12 to $16 per hour due to responsibilities centered on shelving and inventory arrangement. Benefits for order fillers often include performance bonuses, healthcare plans, and paid time off, whereas stockers may have access to similar benefits but with less frequent incentive pay. Salary progression opportunities tend to be more pronounced for order fillers who demonstrate speed and accuracy, enhancing their compensation potential over stockers.

Choosing Between Order Filler and Stocker Roles

Choosing between order filler and stocker roles depends on operational priorities and skill sets; order fillers focus on accurately picking and packing customer orders to meet shipping deadlines, while stockers manage inventory restocking and organization to maintain warehouse efficiency. Companies seeking to optimize fulfillment speed prioritize order fillers with strong attention to detail, whereas those emphasizing inventory accuracy and space utilization benefit from experienced stockers. Understanding workload distribution and core competencies helps streamline warehouse operations and improve overall productivity.

Order Filler vs Stocker Infographic

jobdiv.com

jobdiv.com