An e-waste processor specializes in breaking down electronic devices, extracting valuable metals, and safely handling hazardous materials to prevent environmental contamination. In contrast, a scrap metal sorter primarily separates ferrous and non-ferrous metals for recycling without specifically targeting electronic components. Efficient e-waste processing reduces toxic waste in landfills while scrap metal sorting supports the broader recycling industry by ensuring metals are properly categorized for reuse.

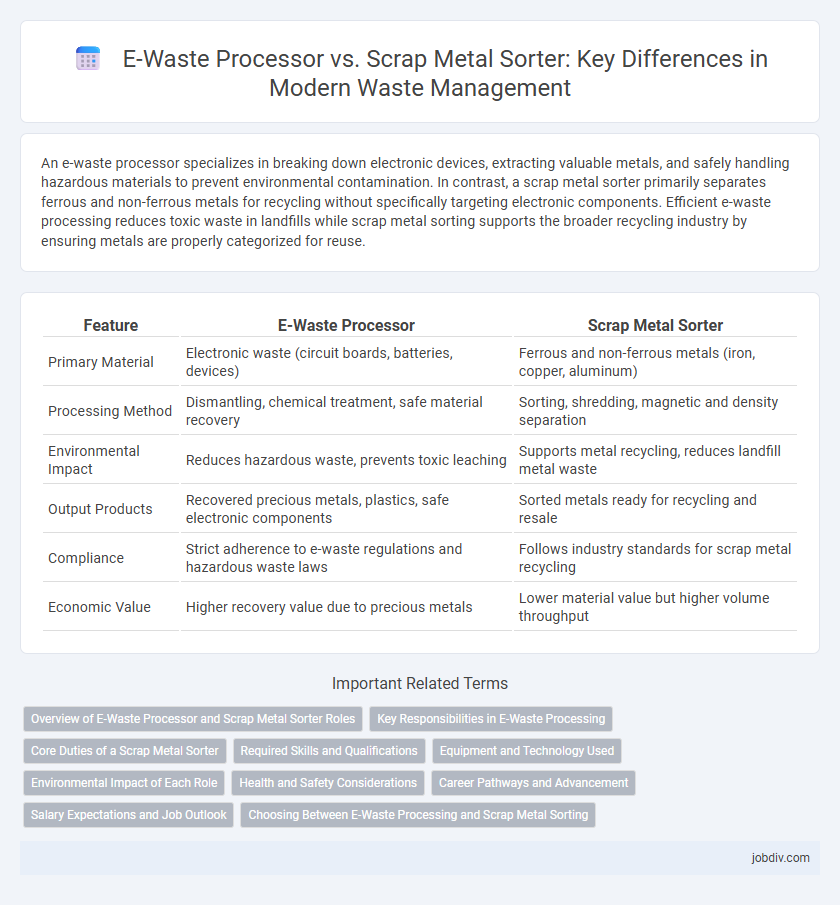

Table of Comparison

| Feature | E-Waste Processor | Scrap Metal Sorter |

|---|---|---|

| Primary Material | Electronic waste (circuit boards, batteries, devices) | Ferrous and non-ferrous metals (iron, copper, aluminum) |

| Processing Method | Dismantling, chemical treatment, safe material recovery | Sorting, shredding, magnetic and density separation |

| Environmental Impact | Reduces hazardous waste, prevents toxic leaching | Supports metal recycling, reduces landfill metal waste |

| Output Products | Recovered precious metals, plastics, safe electronic components | Sorted metals ready for recycling and resale |

| Compliance | Strict adherence to e-waste regulations and hazardous waste laws | Follows industry standards for scrap metal recycling |

| Economic Value | Higher recovery value due to precious metals | Lower material value but higher volume throughput |

Overview of E-Waste Processor and Scrap Metal Sorter Roles

E-waste processors specialize in dismantling and recycling electronic waste by extracting valuable materials such as precious metals, plastics, and glass, reducing environmental impact. Scrap metal sorters focus on categorizing and separating various types of metals from mixed waste streams to optimize recycling efficiency and material recovery. Both roles are crucial in the circular economy, facilitating resource conservation and minimizing landfill contributions.

Key Responsibilities in E-Waste Processing

E-waste processors specialize in dismantling and recovering valuable materials such as precious metals, plastics, and circuit boards from discarded electronic devices, ensuring hazardous substances are safely handled and disposed of. Scrap metal sorters focus on separating ferrous and non-ferrous metals, identifying various metal types to enhance recycling efficiency and material purity. Both roles require precise knowledge of material composition, compliance with environmental regulations, and operation of specialized machinery to maximize resource recovery and minimize ecological impact.

Core Duties of a Scrap Metal Sorter

A scrap metal sorter plays a crucial role in the waste management industry by identifying, separating, and categorizing various types of scrap metals based on composition and quality to ensure efficient recycling. Their core duties include inspecting incoming metal waste, using magnets and sensors to distinguish ferrous from non-ferrous metals, and preparing sorted materials for further processing or sale. Proficiency in operating sorting machinery and adherence to environmental and safety regulations are essential to optimize material recovery and minimize environmental impact.

Required Skills and Qualifications

E-waste processors require technical knowledge in electronics, familiarity with hazardous material handling, and certifications in environmental safety standards to ensure proper dismantling and recycling of electronic components. Scrap metal sorters need expertise in identifying various metal types, physical strength for manual sorting, and experience with magnet-based separation tools to efficiently categorize and prepare metals for recycling. Both roles benefit from adherence to workplace safety protocols and basic understanding of material recovery processes but diverge significantly in specialized skills related to their respective materials.

Equipment and Technology Used

E-waste processors utilize advanced automated dismantling equipment, including robotic arms, conveyor belts, and sensor-based sorting systems to accurately separate electronic components and recover valuable materials such as precious metals and rare earth elements. Scrap metal sorters rely on magnetic separators, eddy current separators, and optical sensors to categorize ferrous and non-ferrous metals efficiently, optimizing yield and purity of recycled metal streams. Both industries increasingly integrate AI-powered systems and real-time data analytics to enhance sorting precision and operational efficiency, reducing environmental impact and increasing material recovery rates.

Environmental Impact of Each Role

E-waste processors reduce hazardous waste by safely extracting valuable materials like gold, silver, and rare earth metals from electronic devices, thus preventing toxic substances such as lead and mercury from contaminating soil and water. Scrap metal sorters contribute to environmental sustainability by categorizing ferrous and non-ferrous metals for recycling, reducing the need for virgin metal extraction and lowering greenhouse gas emissions. While both roles support resource conservation, e-waste processors focus on mitigating electronic contaminants, whereas scrap metal sorters primarily facilitate metal reuse and energy savings.

Health and Safety Considerations

E-waste processors face significant health risks from exposure to toxic substances such as lead, mercury, and cadmium commonly found in electronic waste, necessitating stringent protective measures and specialized ventilation systems. Scrap metal sorters encounter dangers related to heavy machinery, sharp metal edges, and airborne dust, requiring robust personal protective equipment and rigorous safety protocols to prevent injuries. Both occupations demand comprehensive training in hazardous material handling and adherence to occupational safety standards to mitigate long-term health consequences.

Career Pathways and Advancement

E-waste processors specialize in dismantling and recycling electronic components, offering career advancement through certifications in hazardous material handling and sustainable technology management. Scrap metal sorters focus on categorizing and preparing metals for reuse, with progression opportunities involving expertise in metal identification technologies and supply chain logistics. Both fields emphasize skills development in recycling regulations and environmental compliance, creating pathways toward supervisory and managerial roles in waste management.

Salary Expectations and Job Outlook

E-waste processors typically earn higher salaries than scrap metal sorters due to specialized skills in handling hazardous materials and electronic components, with average annual wages ranging from $35,000 to $55,000 compared to $25,000 to $40,000 for scrap metal sorting roles. The job outlook for e-waste processors is more favorable, driven by increasing electronic consumption and strict environmental regulations promoting e-waste recycling, resulting in a projected growth rate of 10-15% over the next decade. Scrap metal sorters face moderate job growth, influenced by fluctuating metal prices and automation advancements that impact manual sorting demand.

Choosing Between E-Waste Processing and Scrap Metal Sorting

Choosing between e-waste processing and scrap metal sorting depends on material specificity and environmental impact priorities. E-waste processors specialize in safely dismantling electronic devices to recover valuable metals like gold, silver, and palladium while reducing hazardous waste, whereas scrap metal sorters focus on categorizing ferrous and non-ferrous metals for recycling efficiency. Opting for e-waste processing is ideal when handling complex electronics, while scrap metal sorting suits bulk metal recovery from construction debris or automotive parts.

E-Waste Processor vs Scrap Metal Sorter Infographic

jobdiv.com

jobdiv.com