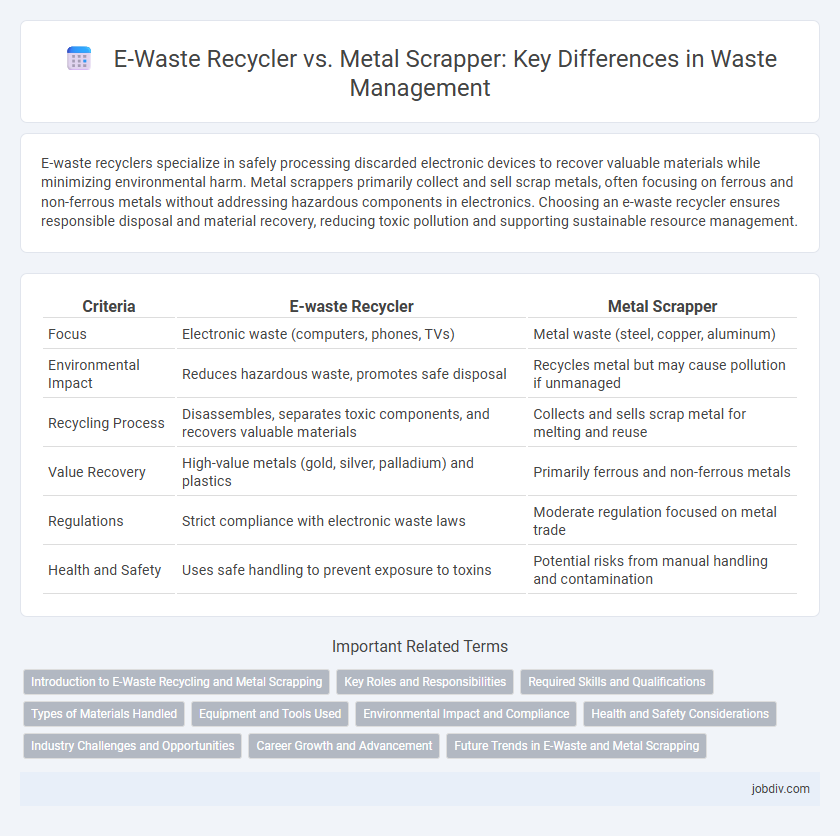

E-waste recyclers specialize in safely processing discarded electronic devices to recover valuable materials while minimizing environmental harm. Metal scrappers primarily collect and sell scrap metals, often focusing on ferrous and non-ferrous metals without addressing hazardous components in electronics. Choosing an e-waste recycler ensures responsible disposal and material recovery, reducing toxic pollution and supporting sustainable resource management.

Table of Comparison

| Criteria | E-waste Recycler | Metal Scrapper |

|---|---|---|

| Focus | Electronic waste (computers, phones, TVs) | Metal waste (steel, copper, aluminum) |

| Environmental Impact | Reduces hazardous waste, promotes safe disposal | Recycles metal but may cause pollution if unmanaged |

| Recycling Process | Disassembles, separates toxic components, and recovers valuable materials | Collects and sells scrap metal for melting and reuse |

| Value Recovery | High-value metals (gold, silver, palladium) and plastics | Primarily ferrous and non-ferrous metals |

| Regulations | Strict compliance with electronic waste laws | Moderate regulation focused on metal trade |

| Health and Safety | Uses safe handling to prevent exposure to toxins | Potential risks from manual handling and contamination |

Introduction to E-Waste Recycling and Metal Scrapping

E-waste recycling involves the processing of discarded electronic devices to recover valuable materials such as gold, copper, and rare earth metals through environmentally sound methods. Metal scrapping focuses on collecting and selling scrap metals like steel, aluminum, and copper, often sourced from obsolete appliances, vehicles, and construction waste. Both practices contribute to resource conservation, but e-waste recycling requires advanced facilities to safely handle hazardous substances contained in electronic components.

Key Roles and Responsibilities

E-waste recyclers specialize in safely dismantling and processing electronic devices to recover valuable materials like gold, copper, and rare earth metals while ensuring hazardous substances such as lead and mercury are properly managed. Metal scrappers primarily collect and sort scrap metals from various sources, including discarded appliances and vehicles, focusing on preparing these materials for melting and reuse in manufacturing. Both roles contribute to resource conservation and environmental protection, but e-waste recyclers require specialized knowledge of electronic components and regulatory compliance for hazardous waste.

Required Skills and Qualifications

E-waste recyclers require specialized knowledge in electronics, including understanding circuit boards, hazardous material handling, and data security protocols, often necessitating certifications in environmental safety and electronics recycling. Metal scrappers primarily need physical strength, familiarity with different metal types, and basic tools for dismantling, with minimal formal qualifications required. Both roles demand adherence to environmental regulations, but e-waste recyclers focus more on technical expertise and safe disposal of toxic components.

Types of Materials Handled

E-waste recyclers primarily handle electronic components such as circuit boards, batteries, and circuit assemblies containing valuable metals like gold, silver, copper, and palladium. Metal scrappers focus on ferrous and non-ferrous metals including steel, aluminum, copper wiring, and brass, typically sourced from industrial scrap, vehicles, and household appliances. The distinction lies in e-waste recyclers targeting complex electronic waste with hazardous substances, while metal scrappers deal with mostly bulk metal materials suitable for melting and reuse.

Equipment and Tools Used

E-waste recyclers primarily utilize advanced sorting machines, shredders, and chemical processing equipment to safely extract valuable metals and components from electronic waste. Metal scrappers depend on manual tools such as hammers, wire cutters, and magnets to dismantle and separate ferrous and non-ferrous metals. The specialized machinery used by e-waste recyclers enables more efficient recovery and environmental compliance compared to the traditional, labor-intensive methods of metal scrappers.

Environmental Impact and Compliance

E-waste recyclers specialize in safely dismantling and processing electronic waste, ensuring hazardous materials like lead, mercury, and cadmium are properly managed to minimize soil and water contamination. Metal scrappers often focus on extracting valuable metals without fully addressing toxic components, potentially leading to environmental pollution and health risks. Compliance with regulatory standards is stricter for certified e-waste recyclers, who follow guidelines such as R2 or e-Stewards certification, promoting responsible recycling and reduced ecological footprint.

Health and Safety Considerations

E-waste recyclers handle hazardous materials such as lead, mercury, and cadmium, requiring strict safety protocols and protective equipment to prevent toxic exposure and environmental contamination. Metal scrappers often work with non-toxic metals but face physical risks from heavy lifting, sharp objects, and machinery without standardized protective measures. Prioritizing worker health, e-waste facilities implement rigorous training and air filtration systems, whereas metal scrapping remains a higher risk for physical injury and unregulated chemical hazards.

Industry Challenges and Opportunities

E-waste recyclers face challenges in safely processing hazardous materials and recovering valuable metals from complex electronic components, while metal scrappers primarily deal with bulk metal recovery but often lack the technology to handle electronic waste's toxic elements. Both industries encounter regulatory pressures around environmental compliance and worker safety, creating opportunities for advanced recycling technologies and sustainable practices. Collaboration between e-waste recyclers and metal scrappers can optimize resource recovery and reduce landfill waste, supporting circular economy goals in the waste management sector.

Career Growth and Advancement

E-waste recyclers experience faster career growth due to the increasing demand for sustainable electronic waste management and advanced technical skills development in handling hazardous materials. Metal scrappers often face limited career advancement opportunities as the industry relies heavily on manual labor and lower technological integration. The shift towards green technologies and strict environmental regulations creates more specialized roles and higher earning potential in e-waste recycling compared to traditional metal scrapping.

Future Trends in E-Waste and Metal Scrapping

Future trends in e-waste recycling emphasize advanced automation and AI-driven sorting technologies that enhance material recovery rates and reduce environmental impact. Metal scrapping continues to evolve with improved smelting techniques and expanded raw material sourcing, addressing resource scarcity and regulatory demands. Both sectors increasingly adopt circular economy principles, promoting sustainable resource management and minimizing landfill contributions.

E-waste Recycler vs Metal Scrapper Infographic

jobdiv.com

jobdiv.com