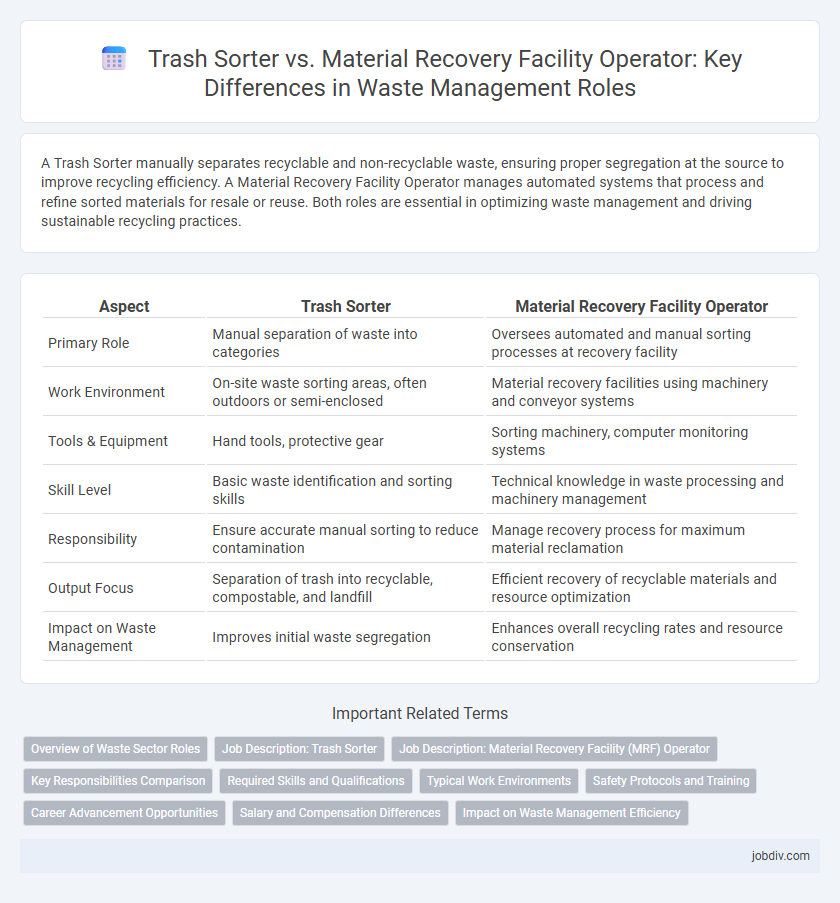

A Trash Sorter manually separates recyclable and non-recyclable waste, ensuring proper segregation at the source to improve recycling efficiency. A Material Recovery Facility Operator manages automated systems that process and refine sorted materials for resale or reuse. Both roles are essential in optimizing waste management and driving sustainable recycling practices.

Table of Comparison

| Aspect | Trash Sorter | Material Recovery Facility Operator |

|---|---|---|

| Primary Role | Manual separation of waste into categories | Oversees automated and manual sorting processes at recovery facility |

| Work Environment | On-site waste sorting areas, often outdoors or semi-enclosed | Material recovery facilities using machinery and conveyor systems |

| Tools & Equipment | Hand tools, protective gear | Sorting machinery, computer monitoring systems |

| Skill Level | Basic waste identification and sorting skills | Technical knowledge in waste processing and machinery management |

| Responsibility | Ensure accurate manual sorting to reduce contamination | Manage recovery process for maximum material reclamation |

| Output Focus | Separation of trash into recyclable, compostable, and landfill | Efficient recovery of recyclable materials and resource optimization |

| Impact on Waste Management | Improves initial waste segregation | Enhances overall recycling rates and resource conservation |

Overview of Waste Sector Roles

Trash Sorters manually separate recyclable materials from general waste, enhancing the efficiency of subsequent processing stages by removing contaminants early. Material Recovery Facility Operators oversee the operation and maintenance of automated systems that further segregate sorted waste into specific material streams such as plastics, metals, and paper for recycling. Both roles are critical in the waste management hierarchy, ensuring higher recovery rates and supporting sustainable waste diversion goals.

Job Description: Trash Sorter

Trash Sorters manually separate recyclable materials from waste streams to ensure proper categorization and reduce landfill contributions. They identify and remove items such as plastics, metals, glass, and paper, improving the efficiency of recycling processes. This role requires attention to detail, physical stamina, and knowledge of waste types to support sustainable waste management.

Job Description: Material Recovery Facility (MRF) Operator

A Material Recovery Facility (MRF) Operator is responsible for overseeing the sorting and processing of recyclable materials to ensure efficient recovery and reuse. They operate advanced machinery to separate various waste streams, such as plastics, metals, paper, and glass, optimizing material quality for recycling markets. Expertise in waste management technologies and adherence to environmental regulations are essential to maintain operational efficiency and reduce landfill contributions.

Key Responsibilities Comparison

Trash Sorters primarily focus on manually separating recyclable materials from general waste to streamline processing and reduce landfill use. Material Recovery Facility (MRF) Operators manage the entire facility's operations, utilizing advanced machinery and technology to efficiently sort, process, and prepare recyclable materials for reuse. While trash sorters ensure accurate initial separation, MRF operators oversee large-scale sorting systems, maintenance, and quality control to maximize resource recovery rates.

Required Skills and Qualifications

Trash Sorters require basic sorting skills, attention to detail, and the ability to identify recyclable materials, often needing minimal formal education or on-the-job training. Material Recovery Facility Operators demand advanced technical knowledge in operating sorting machinery, understanding waste processing systems, and ensuring compliance with environmental regulations, typically requiring specialized certifications or vocational training. Both roles prioritize physical stamina and safety awareness, but operators must also possess problem-solving skills and maintenance expertise to manage complex equipment efficiently.

Typical Work Environments

Trash sorters typically work in sorting centers or collection points where waste materials are manually separated to facilitate recycling. Material recovery facility (MRF) operators are employed in industrial settings equipped with advanced machinery designed to process mixed recyclables on a larger scale. Both roles require environments with safety protocols due to exposure to varied waste types and heavy equipment operation.

Safety Protocols and Training

Trash sorters undergo basic safety training that emphasizes proper handling of waste, use of personal protective equipment (PPE), and hazard recognition to minimize injury risks during manual sorting. Material Recovery Facility (MRF) operators receive advanced training on machine operation, emergency procedures, and environmental compliance to ensure safe processing of recyclables and adherence to regulatory standards. Both roles prioritize ongoing safety education, but MRF operators focus more on technical skills and operational safety protocols due to the complex machinery involved.

Career Advancement Opportunities

Trash sorter positions often serve as entry-level roles with limited advancement, primarily focused on manual waste separation, whereas material recovery facility operators hold more technical responsibilities involving machinery operation and quality control, leading to greater career growth potential. Operators can progress into supervisory or maintenance roles, gaining specialized skills in waste processing technologies and facility management. The demand for sustainability expertise further opens pathways for operators to advance into environmental compliance and waste management consulting careers.

Salary and Compensation Differences

Trash sorter positions typically offer lower salaries, averaging around $25,000 to $35,000 annually, reflecting entry-level responsibilities in manual waste separation. Material Recovery Facility (MRF) operators command higher compensation, often ranging from $40,000 to $60,000 per year, due to their skills in managing complex machinery and overseeing recycling processes. Benefits for MRF operators frequently include performance bonuses and health coverage, which are less common in trash sorter roles.

Impact on Waste Management Efficiency

Trash sorters enhance waste management efficiency by manually separating recyclables and contaminants, improving the quality of recovered materials. Material Recovery Facility (MRF) operators use advanced machinery and automation to process large volumes of waste, increasing throughput and reducing labor costs. Combining manual sorting with MRF technologies optimizes resource recovery rates and minimizes landfill disposal.

Trash Sorter vs Material Recovery Facility Operator Infographic

jobdiv.com

jobdiv.com