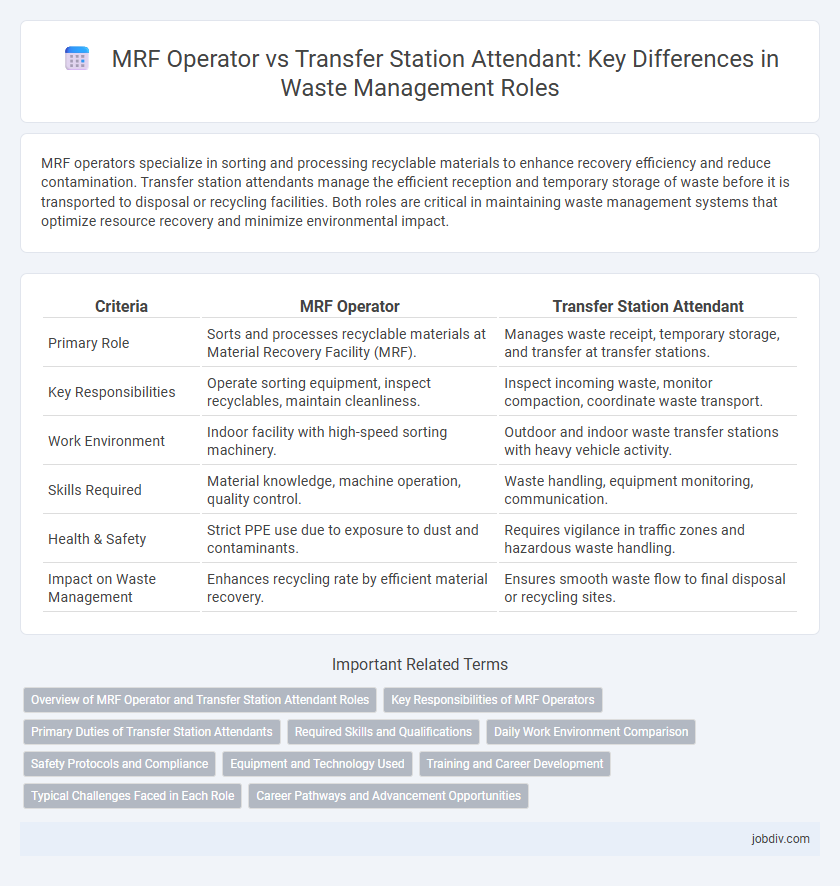

MRF operators specialize in sorting and processing recyclable materials to enhance recovery efficiency and reduce contamination. Transfer station attendants manage the efficient reception and temporary storage of waste before it is transported to disposal or recycling facilities. Both roles are critical in maintaining waste management systems that optimize resource recovery and minimize environmental impact.

Table of Comparison

| Criteria | MRF Operator | Transfer Station Attendant |

|---|---|---|

| Primary Role | Sorts and processes recyclable materials at Material Recovery Facility (MRF). | Manages waste receipt, temporary storage, and transfer at transfer stations. |

| Key Responsibilities | Operate sorting equipment, inspect recyclables, maintain cleanliness. | Inspect incoming waste, monitor compaction, coordinate waste transport. |

| Work Environment | Indoor facility with high-speed sorting machinery. | Outdoor and indoor waste transfer stations with heavy vehicle activity. |

| Skills Required | Material knowledge, machine operation, quality control. | Waste handling, equipment monitoring, communication. |

| Health & Safety | Strict PPE use due to exposure to dust and contaminants. | Requires vigilance in traffic zones and hazardous waste handling. |

| Impact on Waste Management | Enhances recycling rate by efficient material recovery. | Ensures smooth waste flow to final disposal or recycling sites. |

Overview of MRF Operator and Transfer Station Attendant Roles

MRF Operators manage materials recovery facilities by sorting, processing, and preparing recyclable materials for shipment, ensuring compliance with environmental regulations and optimizing resource recovery. Transfer Station Attendants oversee the transfer station's operations, coordinating waste collection, inspecting incoming loads for prohibited items, and maintaining site safety protocols. Both roles are integral to waste management systems, with MRF Operators focused on material processing and Transfer Station Attendants on waste consolidation and site management.

Key Responsibilities of MRF Operators

MRF Operators manage the sorting and processing of recyclable materials to ensure efficient recovery and contamination reduction, operating advanced machinery like conveyor belts and optical sorters. They conduct quality control by inspecting materials for non-recyclable items and maintain operational safety standards within the facility. Accurate record-keeping of throughput volumes and equipment maintenance schedules is critical to optimizing processing efficiency and regulatory compliance.

Primary Duties of Transfer Station Attendants

Transfer Station Attendants manage the efficient intake and sorting of waste, ensuring compliance with safety and environmental regulations. They operate heavy machinery to transfer materials and monitor incoming loads for contamination or hazardous waste. Their role includes documenting waste types and volumes to support waste diversion and recycling efforts.

Required Skills and Qualifications

MRF Operators require expertise in sorting technologies, mechanical maintenance, and knowledge of waste processing regulations to efficiently manage material recovery facilities. Transfer Station Attendants must possess strong organizational skills, safety awareness, and the ability to operate heavy equipment while ensuring compliance with environmental standards. Both roles demand physical stamina, attention to detail, and familiarity with waste handling protocols to maintain operational efficiency and regulatory compliance.

Daily Work Environment Comparison

MRF operators primarily work indoors within Material Recovery Facilities, handling waste sorting, machinery operation, and quality control in a controlled environment with exposure to dust and noise. Transfer station attendants operate outdoors or semi-indoors at waste transfer stations, managing waste unloading, vehicle coordination, and site cleanliness while facing variable weather conditions. Both roles require adherence to safety protocols but differ significantly in physical demands and environmental exposure.

Safety Protocols and Compliance

MRF Operators strictly follow hazardous material handling procedures and personal protective equipment (PPE) standards to minimize exposure risks in waste sorting environments. Transfer Station Attendants prioritize adherence to site traffic control measures and load securement regulations to prevent accidents during waste transfer operations. Both roles ensure compliance with OSHA guidelines and environmental regulations to maintain workplace safety and regulatory standards.

Equipment and Technology Used

MRF operators utilize advanced sorting machinery such as optical sorters, conveyors, and balers to efficiently separate recyclables, while transfer station attendants primarily manage heavy equipment like front-end loaders and compactors to consolidate waste for transport. MRFs employ automated systems and data tracking technology to optimize material recovery rates, whereas transfer stations focus on infrastructure for temporary storage and vehicle logistics. The equipment distinctions reflect the MRF's role in processing and preparing recyclables versus the transfer station's function of waste collection and transfer logistics.

Training and Career Development

MRF operators require specialized training in sorting technologies, contamination identification, and equipment maintenance to ensure efficient material recovery and compliance with environmental regulations. Transfer station attendants focus on training in waste compaction techniques, safety protocols, and traffic management to maintain smooth operations and minimize hazards. Career development for MRF operators often involves advancing to supervisory roles or technical specialist positions, while transfer station attendants can progress to facility management or environmental compliance roles.

Typical Challenges Faced in Each Role

MRF operators frequently encounter challenges such as managing contamination in recyclable materials, maintaining machinery efficiency, and ensuring accurate sorting to meet recycling standards. Transfer station attendants face difficulties in coordinating incoming waste loads, preventing cross-contamination, and optimizing space utilization for efficient waste transfer. Both roles require adherence to safety protocols and efficient handling to minimize environmental impact and operational disruptions.

Career Pathways and Advancement Opportunities

MRF operators specialize in sorting and processing recyclables, developing expertise in materials recovery technology and equipment maintenance, which can lead to roles in plant supervision or environmental compliance. Transfer station attendants manage waste intake and loading operations, gaining skills in logistics and safety compliance, with potential advancement to site management or waste operations coordinator positions. Career pathways in both roles emphasize expertise in waste management systems, offering opportunities for upward mobility through specialized training and certifications.

MRF Operator vs Transfer Station Attendant Infographic

jobdiv.com

jobdiv.com