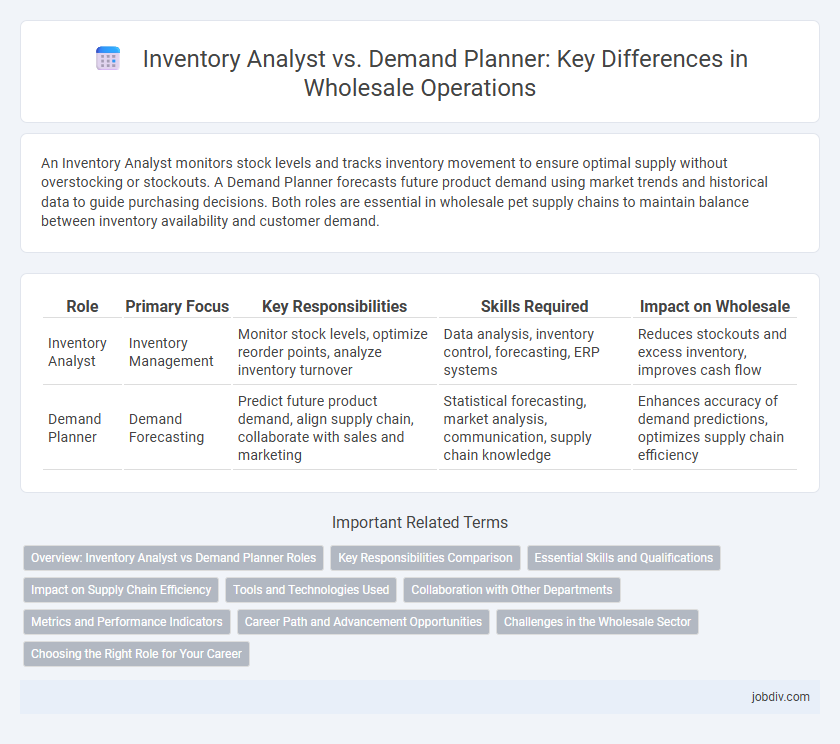

An Inventory Analyst monitors stock levels and tracks inventory movement to ensure optimal supply without overstocking or stockouts. A Demand Planner forecasts future product demand using market trends and historical data to guide purchasing decisions. Both roles are essential in wholesale pet supply chains to maintain balance between inventory availability and customer demand.

Table of Comparison

| Role | Primary Focus | Key Responsibilities | Skills Required | Impact on Wholesale |

|---|---|---|---|---|

| Inventory Analyst | Inventory Management | Monitor stock levels, optimize reorder points, analyze inventory turnover | Data analysis, inventory control, forecasting, ERP systems | Reduces stockouts and excess inventory, improves cash flow |

| Demand Planner | Demand Forecasting | Predict future product demand, align supply chain, collaborate with sales and marketing | Statistical forecasting, market analysis, communication, supply chain knowledge | Enhances accuracy of demand predictions, optimizes supply chain efficiency |

Overview: Inventory Analyst vs Demand Planner Roles

Inventory Analysts focus on monitoring stock levels, analyzing inventory turnover, and identifying discrepancies to optimize warehouse efficiency and reduce holding costs. Demand Planners forecast customer demand using historical sales data, market trends, and seasonal factors to ensure accurate production and procurement plans. Both roles collaborate closely to balance supply and demand, minimizing stockouts and excess inventory in wholesale operations.

Key Responsibilities Comparison

Inventory Analysts focus on monitoring stock levels, analyzing inventory turnover, and ensuring optimal stock availability to reduce carrying costs. Demand Planners forecast customer demand using historical sales data, market trends, and predictive analytics to inform procurement and production decisions. Both roles collaborate to balance supply chain efficiency, but Inventory Analysts prioritize inventory accuracy while Demand Planners drive demand forecasting accuracy.

Essential Skills and Qualifications

Inventory Analysts require strong data analysis skills, proficiency in inventory management software, and expertise in forecasting demand to optimize stock levels and reduce holding costs. Demand Planners need advanced skills in market research, statistical forecasting, and supply chain coordination to accurately predict customer demand and align procurement strategies. Both roles demand excellent communication and problem-solving abilities, but Inventory Analysts focus more on operational efficiency while Demand Planners emphasize strategic demand forecasting.

Impact on Supply Chain Efficiency

Inventory Analysts optimize stock levels by monitoring inventory turnover rates and identifying slow-moving products, directly reducing carrying costs and minimizing stockouts. Demand Planners forecast customer demand using historical sales data and market trends, enabling accurate production scheduling and procurement decisions. Combining these roles enhances supply chain efficiency through balanced inventory control and demand-driven replenishment strategies.

Tools and Technologies Used

Inventory Analysts utilize advanced inventory management software such as NetSuite and SAP to track stock levels, forecast inventory needs, and optimize warehouse operations. Demand Planners rely heavily on demand forecasting tools like Oracle Demantra and Anaplan, incorporating predictive analytics and machine learning algorithms to anticipate market trends and customer demand. Both roles benefit from integrating data visualization platforms such as Tableau and Power BI to enhance reporting accuracy and decision-making processes.

Collaboration with Other Departments

Inventory Analysts collaborate closely with procurement, sales, and warehouse teams to maintain accurate stock levels and optimize inventory turnover. Demand Planners coordinate with marketing, sales forecasting, and finance departments to predict customer demand and develop effective replenishment strategies. Both roles rely on cross-functional communication to align inventory availability with market needs and company goals in wholesale operations.

Metrics and Performance Indicators

Inventory Analysts prioritize metrics such as stock turnover ratio, carrying costs, and order accuracy to optimize warehouse efficiency and reduce excess inventory. Demand Planners focus on forecast accuracy, bias, and service level performance to align inventory levels with actual market demand and improve replenishment cycles. Both roles leverage key performance indicators (KPIs) like fill rate and lead time variability to synchronize supply chain operations and enhance wholesale distribution profitability.

Career Path and Advancement Opportunities

Inventory Analysts in wholesale primarily focus on tracking stock levels and optimizing inventory turnover, building expertise in supply chain data analytics that can lead to roles such as Inventory Manager or Supply Chain Analyst. Demand Planners specialize in forecasting customer demand using statistical models and market trends, often progressing to senior forecasting roles or strategic positions like Sales and Operations Planning (S&OP) Manager. Career advancement for both roles benefits from proficiency in ERP systems, data analysis tools, and cross-functional collaboration, with opportunities to move into broader supply chain management or commercial strategy roles.

Challenges in the Wholesale Sector

Inventory Analysts face challenges in the wholesale sector such as managing vast product assortments and accurately tracking stock levels to avoid overstock or stockouts. Demand Planners struggle with forecasting demand fluctuations driven by seasonal trends, market volatility, and shifting consumer preferences in wholesale markets. Both roles require advanced data analytics and collaborative communication with supply chain teams to optimize inventory turnover and reduce holding costs.

Choosing the Right Role for Your Career

Inventory Analysts specialize in managing stock levels, optimizing warehouse space, and ensuring accurate inventory records to prevent overstocking or stockouts in wholesale operations. Demand Planners focus on forecasting customer demand using historical sales data, market trends, and predictive analytics to align inventory and production schedules with market needs. Choosing the right role depends on your strengths in data analysis versus strategic forecasting, with Inventory Analysts excelling in operational control and Demand Planners driving proactive supply chain decisions.

Inventory Analyst vs Demand Planner Infographic

jobdiv.com

jobdiv.com