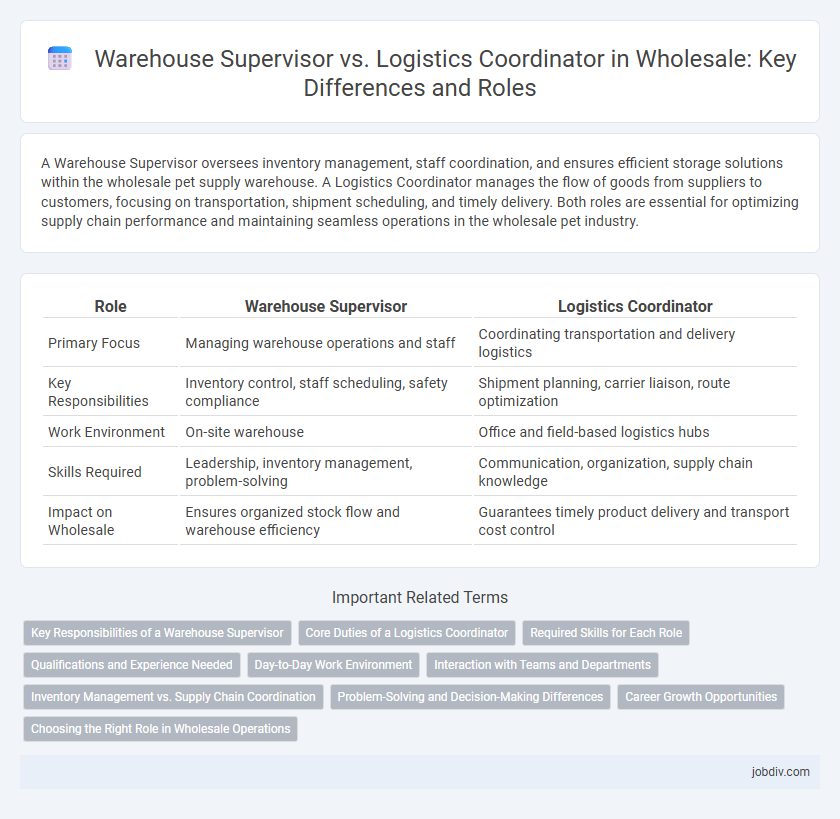

A Warehouse Supervisor oversees inventory management, staff coordination, and ensures efficient storage solutions within the wholesale pet supply warehouse. A Logistics Coordinator manages the flow of goods from suppliers to customers, focusing on transportation, shipment scheduling, and timely delivery. Both roles are essential for optimizing supply chain performance and maintaining seamless operations in the wholesale pet industry.

Table of Comparison

| Role | Warehouse Supervisor | Logistics Coordinator |

|---|---|---|

| Primary Focus | Managing warehouse operations and staff | Coordinating transportation and delivery logistics |

| Key Responsibilities | Inventory control, staff scheduling, safety compliance | Shipment planning, carrier liaison, route optimization |

| Work Environment | On-site warehouse | Office and field-based logistics hubs |

| Skills Required | Leadership, inventory management, problem-solving | Communication, organization, supply chain knowledge |

| Impact on Wholesale | Ensures organized stock flow and warehouse efficiency | Guarantees timely product delivery and transport cost control |

Key Responsibilities of a Warehouse Supervisor

A Warehouse Supervisor manages inventory accuracy, oversees daily warehouse operations, and ensures compliance with safety standards in wholesale environments. They coordinate staff schedules, monitor shipment processing, and implement efficient storage systems to optimize space utilization. Maintaining quality control and resolving logistical discrepancies are critical responsibilities that support seamless supply chain management.

Core Duties of a Logistics Coordinator

A Logistics Coordinator in wholesale manages the efficient movement of goods from suppliers to customers, coordinating shipment schedules, tracking inventory levels, and liaising with carriers to ensure timely delivery. Key duties include optimizing transportation routes, preparing shipping documentation, and resolving logistical issues to minimize delays and costs. This role requires strong communication and organizational skills to maintain seamless supply chain operations, distinguishing it from a Warehouse Supervisor who primarily oversees storage, inventory control, and on-site staff management.

Required Skills for Each Role

Warehouse Supervisors require strong leadership abilities, inventory management expertise, and proficiency in warehouse management systems (WMS) to ensure efficient storage and retrieval processes. Logistics Coordinators need excellent organizational skills, knowledge of transportation regulations, and the ability to optimize supply chain schedules to facilitate timely deliveries. Both roles demand effective communication skills and a solid understanding of safety standards within wholesale distribution environments.

Qualifications and Experience Needed

A Warehouse Supervisor typically requires hands-on experience in inventory management, team leadership, and familiarity with warehouse safety protocols, often supported by certifications such as OSHA or forklift operation. A Logistics Coordinator generally needs expertise in supply chain management, transportation planning, and proficiency with logistics software like ERP systems, alongside strong analytical skills and a background in business or logistics administration. Both roles benefit from problem-solving abilities and effective communication, but the Warehouse Supervisor focuses more on operational oversight while the Logistics Coordinator emphasizes strategic planning and coordination.

Day-to-Day Work Environment

A Warehouse Supervisor manages inventory control, oversees loading and unloading operations, and ensures safety compliance within the warehouse environment. A Logistics Coordinator focuses on planning and coordinating transportation schedules, tracking shipments, and liaising with carriers to optimize delivery efficiency. Both roles require strong organizational skills, but the supervisor is more hands-on with warehouse staff, while the coordinator handles external logistics communication.

Interaction with Teams and Departments

Warehouse Supervisors oversee daily operations, ensuring smooth communication between inventory, shipping, and receiving teams to maintain efficient workflow in wholesale environments. Logistics Coordinators facilitate coordination among procurement, distribution, and customer service departments, optimizing supply chain processes and resolving cross-functional challenges. Effective interaction between these roles enhances overall operational efficiency and timely order fulfillment across all wholesale departments.

Inventory Management vs. Supply Chain Coordination

Warehouse Supervisors specialize in inventory management by overseeing stock levels, organizing storage, and ensuring accurate order fulfillment within the warehouse environment. Logistics Coordinators manage supply chain coordination by planning and tracking shipments, liaising with suppliers and carriers, and optimizing transportation efficiency. Effective wholesale operations require both roles to collaborate closely to maintain inventory accuracy and streamline distribution processes.

Problem-Solving and Decision-Making Differences

Warehouse Supervisors focus on solving operational issues such as inventory discrepancies, equipment malfunctions, and workforce allocation to maintain efficient warehouse workflows. Logistics Coordinators address broader supply chain challenges, including route optimization, carrier negotiations, and delivery scheduling to ensure timely distribution. Decision-making for Warehouse Supervisors emphasizes immediate, on-site problem resolution, while Logistics Coordinators prioritize strategic planning and coordination across multiple transportation and storage channels.

Career Growth Opportunities

Warehouse Supervisors often advance by gaining expertise in inventory management and team leadership, leading to roles such as Operations Manager or Distribution Center Manager. Logistics Coordinators develop skills in supply chain analysis and vendor relations, positioning them for careers in Supply Chain Management or Logistics Planning. Both roles offer robust career growth through specialization and expanding responsibilities in the wholesale industry.

Choosing the Right Role in Wholesale Operations

Warehouse Supervisors oversee inventory management and daily warehouse operations, ensuring efficient storage and timely dispatch in wholesale environments. Logistics Coordinators plan and coordinate the transportation and delivery of goods, optimizing supply chain workflows to minimize delays and costs. Selecting the right role depends on whether the priority lies in hands-on warehouse control or strategic logistics planning within wholesale operations.

Warehouse Supervisor vs Logistics Coordinator Infographic

jobdiv.com

jobdiv.com