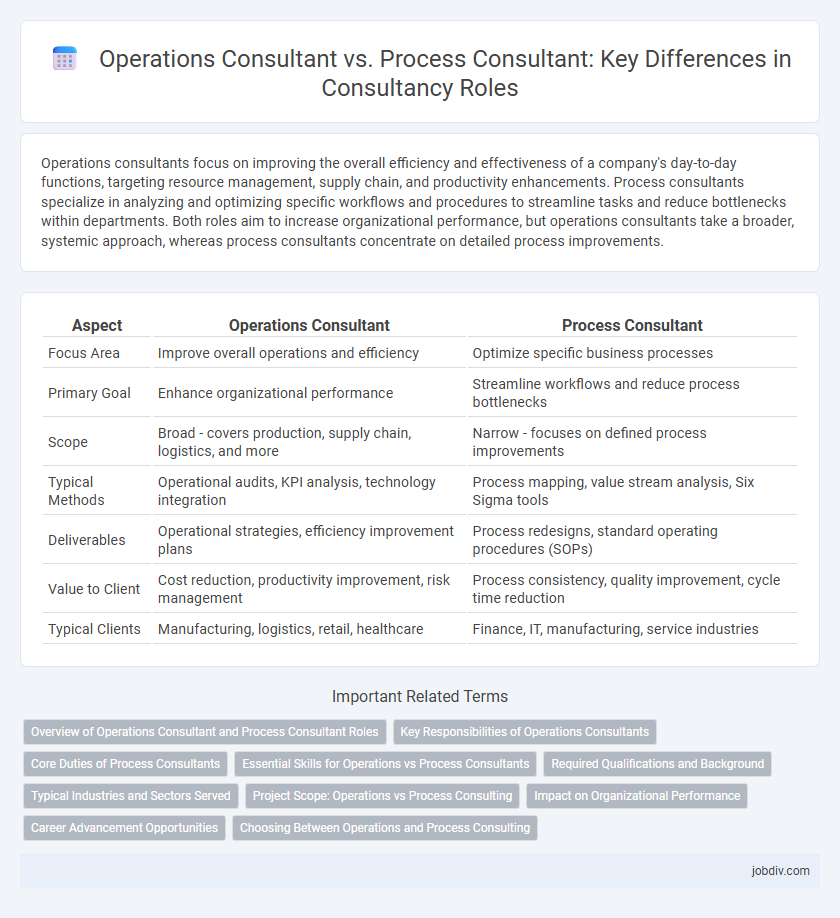

Operations consultants focus on improving the overall efficiency and effectiveness of a company's day-to-day functions, targeting resource management, supply chain, and productivity enhancements. Process consultants specialize in analyzing and optimizing specific workflows and procedures to streamline tasks and reduce bottlenecks within departments. Both roles aim to increase organizational performance, but operations consultants take a broader, systemic approach, whereas process consultants concentrate on detailed process improvements.

Table of Comparison

| Aspect | Operations Consultant | Process Consultant |

|---|---|---|

| Focus Area | Improve overall operations and efficiency | Optimize specific business processes |

| Primary Goal | Enhance organizational performance | Streamline workflows and reduce process bottlenecks |

| Scope | Broad - covers production, supply chain, logistics, and more | Narrow - focuses on defined process improvements |

| Typical Methods | Operational audits, KPI analysis, technology integration | Process mapping, value stream analysis, Six Sigma tools |

| Deliverables | Operational strategies, efficiency improvement plans | Process redesigns, standard operating procedures (SOPs) |

| Value to Client | Cost reduction, productivity improvement, risk management | Process consistency, quality improvement, cycle time reduction |

| Typical Clients | Manufacturing, logistics, retail, healthcare | Finance, IT, manufacturing, service industries |

Overview of Operations Consultant and Process Consultant Roles

Operations Consultants focus on enhancing overall business efficiency by analyzing and improving organizational workflows, resource management, and operations strategy to drive cost reduction and productivity growth. Process Consultants specialize in identifying, mapping, and refining specific business processes to streamline activities, reduce errors, and ensure compliance with industry standards. Both roles collaborate to align operational execution with strategic goals, but Operations Consultants take a broader scope while Process Consultants concentrate on detailed process optimization.

Key Responsibilities of Operations Consultants

Operations consultants specialize in improving an organization's overall efficiency by analyzing and redesigning core business processes, managing supply chain logistics, and optimizing resource allocation. They focus on enhancing operational performance metrics such as cost reduction, productivity, and quality control across multiple departments. Key responsibilities include assessing workflow bottlenecks, implementing technology solutions, and recommending strategies for operational scalability and risk management.

Core Duties of Process Consultants

Process consultants specialize in analyzing and enhancing organizational workflows to improve efficiency and productivity. Their core duties include mapping existing processes, identifying bottlenecks, and designing optimized procedures that align with company objectives. They collaborate closely with stakeholders to implement continuous improvement strategies and ensure sustainable operational excellence.

Essential Skills for Operations vs Process Consultants

Operations consultants excel in strategic planning, resource management, and performance optimization to enhance overall business efficiency. Process consultants specialize in workflow analysis, process mapping, and continuous improvement methodologies like Lean and Six Sigma to streamline operations. Both roles require strong analytical skills, effective communication, and the ability to implement change management for sustainable results.

Required Qualifications and Background

Operations consultants typically require a strong background in business administration, supply chain management, and data analytics, with expertise in optimizing organizational performance and operational efficiency. Process consultants often possess qualifications in industrial engineering, quality management, and Lean Six Sigma methodologies, focusing on designing, analyzing, and improving specific business processes. Both roles demand excellent problem-solving skills and experience with change management, though operations consultants lean more toward broad organizational improvements while process consultants specialize in detailed process optimization.

Typical Industries and Sectors Served

Operations consultants typically serve manufacturing, logistics, and retail industries, focusing on optimizing supply chain management, production efficiency, and operational workflows. Process consultants concentrate on financial services, healthcare, and information technology sectors by refining business processes, enhancing compliance, and improving service delivery frameworks. Both roles drive performance improvements but target different aspects of organizational effectiveness tailored to industry-specific challenges.

Project Scope: Operations vs Process Consulting

Operations consultants focus on optimizing overall business performance by analyzing and improving end-to-end operational workflows, resource allocation, and supply chain management within a project's scope. Process consultants specialize in detailed mapping, assessment, and redesign of specific business processes to enhance efficiency, reduce waste, and streamline task execution. Project scope in operations consulting tends to encompass broader organizational systems, while process consulting targets discrete workflows for incremental improvements.

Impact on Organizational Performance

Operations consultants optimize supply chain efficiency, resource allocation, and production workflows, directly enhancing organizational performance through cost reduction and improved output quality. Process consultants focus on refining business processes, streamlining workflows, and implementing continuous improvement methodologies like Lean and Six Sigma to increase speed, accuracy, and customer satisfaction. Both roles drive performance improvement, with operations consultants targeting operational execution and process consultants emphasizing systemic process enhancements.

Career Advancement Opportunities

Operations consultants focus on optimizing overall business functions, offering broader career advancement opportunities into executive roles such as Chief Operating Officer or Operations Director. Process consultants specialize in improving specific workflows and methodologies, often progressing into expert roles like Process Improvement Manager or Lean Six Sigma Coach. Both career paths emphasize strategic problem-solving skills but differ in scope and trajectory within consultancy firms.

Choosing Between Operations and Process Consulting

Choosing between operations consulting and process consulting depends on business priorities: operations consulting focuses on improving overall organizational efficiency, resource management, and performance metrics, while process consulting targets the optimization and redesign of specific workflows and procedures. Businesses aiming to enhance end-to-end operational effectiveness may benefit more from operations consultants, whereas those seeking detailed process improvements and reduced cycle times should consider process consultants. Evaluating current challenges, desired outcomes, and scalability needs helps determine the most suitable consulting approach for sustainable growth.

Operations Consultant vs Process Consultant Infographic

jobdiv.com

jobdiv.com