Diamond drillers use a diamond-embedded drill bit to extract core samples, providing precise geological information crucial for mineral exploration. Reverse circulation drillers employ high-pressure air to return rock cuttings to the surface, enabling faster and more cost-effective sampling in softer formations. Selecting between these methods depends on the required sample quality and the geological conditions of the mining site.

Table of Comparison

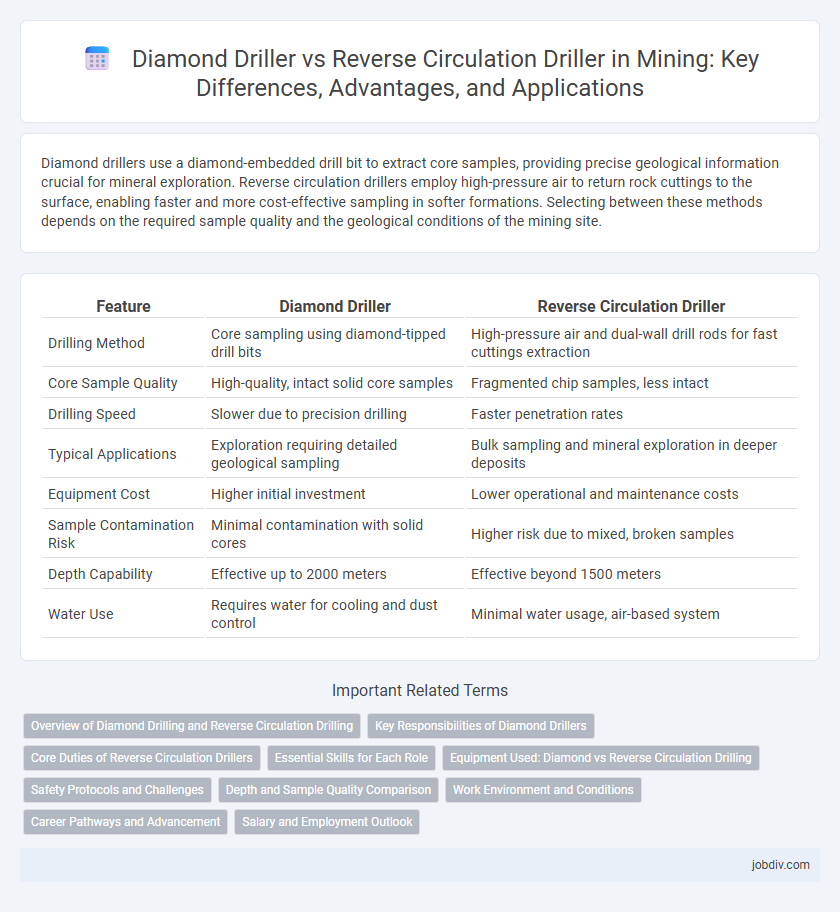

| Feature | Diamond Driller | Reverse Circulation Driller |

|---|---|---|

| Drilling Method | Core sampling using diamond-tipped drill bits | High-pressure air and dual-wall drill rods for fast cuttings extraction |

| Core Sample Quality | High-quality, intact solid core samples | Fragmented chip samples, less intact |

| Drilling Speed | Slower due to precision drilling | Faster penetration rates |

| Typical Applications | Exploration requiring detailed geological sampling | Bulk sampling and mineral exploration in deeper deposits |

| Equipment Cost | Higher initial investment | Lower operational and maintenance costs |

| Sample Contamination Risk | Minimal contamination with solid cores | Higher risk due to mixed, broken samples |

| Depth Capability | Effective up to 2000 meters | Effective beyond 1500 meters |

| Water Use | Requires water for cooling and dust control | Minimal water usage, air-based system |

Overview of Diamond Drilling and Reverse Circulation Drilling

Diamond drilling uses a rotating drill bit embedded with industrial diamonds to create core samples, providing precise geological information and valuable mineral data. Reverse circulation drilling employs dual-walled drill rods to efficiently extract rock cuttings via compressed air, offering faster penetration rates and cost-effective sampling for mineral exploration. Both methods are essential in mining for accurate subsurface analysis but differ in sample quality, extraction speed, and application suitability.

Key Responsibilities of Diamond Drillers

Diamond drillers operate specialized core drilling rigs to extract cylindrical rock samples from deep underground, enabling detailed geological analysis essential for mineral exploration. Their key responsibilities include maintaining and operating diamond drill equipment, monitoring drilling parameters to optimize core recovery, and ensuring adherence to safety protocols during drilling operations. Precise geological data collection and sample preservation differentiate diamond drillers from reverse circulation drillers, who primarily focus on faster but less detailed material extraction.

Core Duties of Reverse Circulation Drillers

Reverse Circulation Drillers specialize in extracting rock samples by using dual-walled drill pipes that separate drill cuttings from the drilling fluid, ensuring faster and cleaner sample recovery compared to Diamond Drillers. Their core duties include operating and maintaining high-pressure drilling rigs, monitoring drilling parameters to optimize penetration rates, and collecting bulk samples used primarily for mineral exploration and grade control. Precision in maintaining drill bit pressure and efficient removal of cuttings directly influences sampling accuracy and overall project efficiency in mining operations.

Essential Skills for Each Role

Diamond drillers require precise control and expertise in operating core drilling rigs to extract intact rock samples for mineral analysis, emphasizing steady hand coordination and depth management. Reverse circulation drillers specialize in efficient large-scale drilling using dual-walled drill pipes to swiftly collect rock chips, focusing on equipment maintenance skills and quick decision-making to optimize sample recovery. Both roles demand strong technical knowledge of drill mechanics, safety protocols, and troubleshooting to ensure accurate data collection in diverse mining conditions.

Equipment Used: Diamond vs Reverse Circulation Drilling

Diamond drilling equipment utilizes a core barrel fitted with industrial-grade diamond-impregnated drill bits to extract precise cylindrical rock samples, enabling detailed geological analysis. Reverse circulation drilling systems employ dual-walled drill rods and high-pressure air to efficiently return rock cuttings to the surface, optimizing sample recovery and minimizing contamination. The choice between diamond and reverse circulation drilling equipment hinges on the project's requirement for sample integrity and drilling speed in mineral exploration.

Safety Protocols and Challenges

Diamond Drillers rely on diamond-tipped bits to penetrate hard rock formations, requiring strict safety protocols to manage high vibration and the risk of core barrel jamming, which can lead to drill string failure. Reverse Circulation Drillers use dual-wall drill pipes to circulate drilling fluid and cuttings simultaneously, necessitating rigorous inspection to prevent blowouts and ensure proper sealing of the inner and outer pipes. Both drilling methods face challenges including maintaining operator safety in confined spaces and managing the exposure to airborne silica dust during rock fragment extraction.

Depth and Sample Quality Comparison

Diamond drillers achieve depths exceeding 1,000 meters with core samples that retain intact rock structures, ensuring high sample integrity for precise geological analysis. Reverse circulation drillers typically reach depths up to 500 meters, delivering rock chip samples that are less intact but provide faster recovery rates and cost efficiency. While diamond drilling excels in detailed subsurface information through continuous core samples, reverse circulation drilling prioritizes speed and sample volume, affecting the precision of mineral grade estimation.

Work Environment and Conditions

Diamond drillers operate in highly controlled, often underground or remote environments requiring precise core sampling with minimal contamination, handling slower drilling speeds and high-pressure water usage. Reverse circulation drillers work primarily in surface or open-pit settings, managing faster drilling rates with dual tubing systems that optimize cuttings removal amid dustier, more abrasive conditions. Both roles demand rigorous safety protocols but differ significantly in noise levels, vibration exposure, and equipment complexity due to their distinct operational focuses.

Career Pathways and Advancement

Diamond drillers advance through specialized training in core sampling and geological analysis, often progressing to supervisory roles in exploration projects. Reverse circulation drillers gain expertise in efficient rock fragment extraction and equipment maintenance, with career growth leading to rig management and operational planning positions. Both pathways offer opportunities for certification and transition into broader mining engineering or project management roles.

Salary and Employment Outlook

Diamond drillers typically earn higher salaries ranging from $60,000 to $90,000 annually due to specialized skills in core sampling and precision drilling, while reverse circulation drillers' salaries average between $50,000 and $75,000 given their focus on bulk sampling for mineral exploration. Employment opportunities for diamond drillers are projected to grow steadily with increased demand in deep mineral exploration and mining projects worldwide. Reverse circulation drillers also face positive job prospects, particularly in regions with active resource extraction industries emphasizing rapid and efficient ore recovery methods.

Diamond Driller vs Reverse Circulation Driller Infographic

jobdiv.com

jobdiv.com