Ore haulers are heavy-duty vehicles designed for transporting large quantities of mined ore efficiently across mining sites, while rock breakers are specialized machines used to break oversized rocks and boulders into manageable pieces for easier handling and processing. Ore haulers maximize productivity by ensuring continuous material flow, whereas rock breakers focus on minimizing equipment damage and downtime caused by large, unmanageable rocks. Effective integration of both machines significantly enhances operational efficiency and safety in mining environments.

Table of Comparison

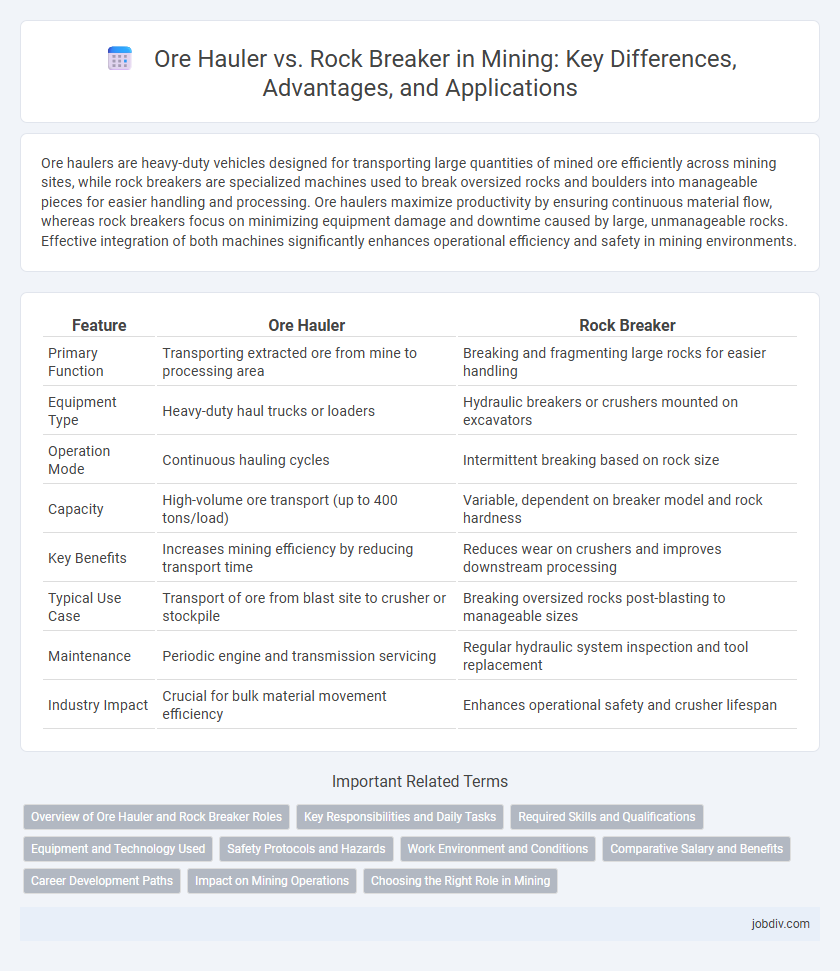

| Feature | Ore Hauler | Rock Breaker |

|---|---|---|

| Primary Function | Transporting extracted ore from mine to processing area | Breaking and fragmenting large rocks for easier handling |

| Equipment Type | Heavy-duty haul trucks or loaders | Hydraulic breakers or crushers mounted on excavators |

| Operation Mode | Continuous hauling cycles | Intermittent breaking based on rock size |

| Capacity | High-volume ore transport (up to 400 tons/load) | Variable, dependent on breaker model and rock hardness |

| Key Benefits | Increases mining efficiency by reducing transport time | Reduces wear on crushers and improves downstream processing |

| Typical Use Case | Transport of ore from blast site to crusher or stockpile | Breaking oversized rocks post-blasting to manageable sizes |

| Maintenance | Periodic engine and transmission servicing | Regular hydraulic system inspection and tool replacement |

| Industry Impact | Crucial for bulk material movement efficiency | Enhances operational safety and crusher lifespan |

Overview of Ore Hauler and Rock Breaker Roles

Ore haulers are heavy-duty vehicles designed to transport large quantities of mined ore from extraction sites to processing or loading areas efficiently, minimizing downtime in mining operations. Rock breakers are specialized machines equipped with hydraulic arms and powerful hammers to precisely fracture oversized rocks and debris, facilitating easier handling and crushing processes. Both roles are critical in streamlining material flow and enhancing productivity in mining operations by optimizing ore handling and size reduction.

Key Responsibilities and Daily Tasks

Ore haulers are responsible for transporting extracted ore from the mining site to processing areas, ensuring timely and efficient material movement using heavy-duty haul trucks. Rock breakers perform the critical task of breaking oversized rocks and boulders in crushers or stockpiles to facilitate smoother loading and processing workflows. Daily tasks for ore haulers include vehicle inspection, load management, and adherence to safety protocols, while rock breakers focus on operating hydraulic breakers, monitoring rock fragmentation, and maintaining breaker equipment.

Required Skills and Qualifications

Operating an ore hauler requires proficiency in heavy machinery handling, mechanical knowledge, and adherence to safety protocols to efficiently transport mined materials. Rock breaker operators must possess skills in hydraulic equipment operation, precision control to break large rocks safely, and understanding of mining site geology to optimize fragmentation. Both roles demand physical stamina, attention to detail, and certifications such as Mine Safety and Health Administration (MSHA) compliance and equipment-specific licenses.

Equipment and Technology Used

Ore haulers utilize heavy-duty trucks equipped with advanced GPS and load management systems to efficiently transport extracted minerals from the mine site to processing facilities. Rock breakers employ hydraulic arms with powerful impact tools and precision sensors, enabling controlled fragmentation of oversized rocks to improve crusher efficiency. Both machines integrate real-time data monitoring and automation technology to optimize excavation and material handling processes in mining operations.

Safety Protocols and Hazards

Ore haulers and rock breakers present distinct safety protocols due to their operational hazards in mining environments. Ore haulers require rigorous training for maneuvering heavy loads on uneven terrain, emphasizing collision avoidance and load securement to prevent spills and tipping accidents. Rock breakers demand strict adherence to protocols addressing flying debris, noise exposure, and proximity hazards, including the use of protective barriers, regular equipment maintenance, and personal protective equipment (PPE) to mitigate risks of injury from rock fragmentation.

Work Environment and Conditions

Ore haulers operate primarily in open-pit mining environments, navigating rough terrain and transporting large volumes of extracted ore under variable weather conditions. Rock breakers are stationed at crusher sites or underground mines, where they work in confined spaces exposed to dust, noise, and vibrations from breaking oversized rocks. Both roles demand stringent safety protocols, with ore haulers facing risks of vehicular accidents and rock breakers managing hazards related to heavy machinery operation and rock fragmentation.

Comparative Salary and Benefits

Ore haulers typically earn higher salaries than rock breakers due to the greater responsibility and skill required for operating heavy hauling machinery in mining operations. Benefits for ore haulers often include comprehensive health insurance, retirement plans, and performance bonuses, reflecting the demanding nature of their role. In contrast, rock breakers receive competitive wages but fewer performance incentives, with benefits focused more on safety equipment and training programs.

Career Development Paths

Ore haulers specialize in transporting large quantities of mined material, offering career advancement through roles in logistics management, equipment maintenance supervision, and safety compliance coordination. Rock breaker operators develop expertise in fragmentation techniques, progressing towards positions in equipment operation training, site operations management, and technical consulting on rock mechanics. Both careers require strong knowledge of mining equipment and safety protocols, with opportunities to evolve into supervisory or technical specialist roles within the mining industry.

Impact on Mining Operations

Ore haulers significantly enhance mining operations by improving ore transport efficiency, reducing cycle times, and increasing overall productivity through rapid and reliable material movement. Rock breakers optimize mining safety and continuous fragmentation processes by minimizing equipment downtime and enabling precise size reduction directly at the excavation site. Together, these machines streamline the mining workflow, lowering operational costs and boosting extraction rates.

Choosing the Right Role in Mining

Ore haulers maximize efficiency by transporting large volumes of extracted ore from the mining site to processing facilities, using heavy-duty trucks designed for high payload capacity and rugged terrain. Rock breakers play a critical role in enhancing material handling by breaking oversized rocks into manageable pieces, ensuring continuous operation of crushers and conveyors. Selecting the right equipment depends on production goals, site conditions, and integration with other mining operations to maintain workflow efficiency and cost-effectiveness.

Ore Hauler vs Rock Breaker Infographic

jobdiv.com

jobdiv.com