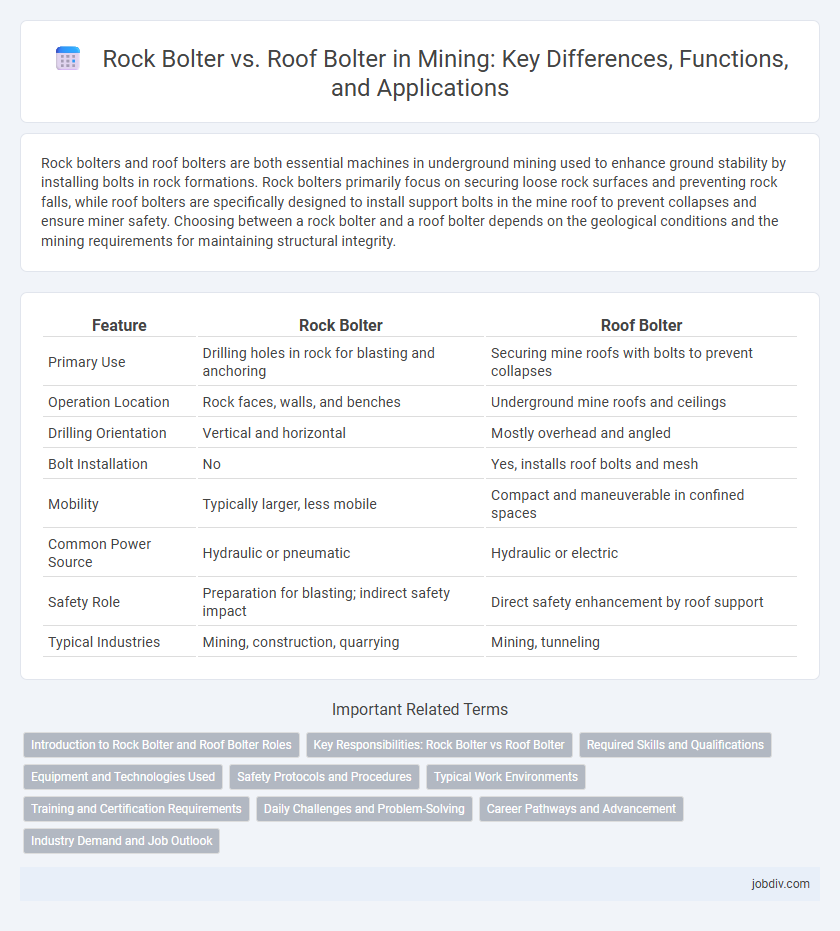

Rock bolters and roof bolters are both essential machines in underground mining used to enhance ground stability by installing bolts in rock formations. Rock bolters primarily focus on securing loose rock surfaces and preventing rock falls, while roof bolters are specifically designed to install support bolts in the mine roof to prevent collapses and ensure miner safety. Choosing between a rock bolter and a roof bolter depends on the geological conditions and the mining requirements for maintaining structural integrity.

Table of Comparison

| Feature | Rock Bolter | Roof Bolter |

|---|---|---|

| Primary Use | Drilling holes in rock for blasting and anchoring | Securing mine roofs with bolts to prevent collapses |

| Operation Location | Rock faces, walls, and benches | Underground mine roofs and ceilings |

| Drilling Orientation | Vertical and horizontal | Mostly overhead and angled |

| Bolt Installation | No | Yes, installs roof bolts and mesh |

| Mobility | Typically larger, less mobile | Compact and maneuverable in confined spaces |

| Common Power Source | Hydraulic or pneumatic | Hydraulic or electric |

| Safety Role | Preparation for blasting; indirect safety impact | Direct safety enhancement by roof support |

| Typical Industries | Mining, construction, quarrying | Mining, tunneling |

Introduction to Rock Bolter and Roof Bolter Roles

Rock bolters and roof bolters play crucial roles in mining operations by stabilizing underground rock formations to prevent collapses. Rock bolters specifically install rock bolts into mining walls or ceilings to reinforce weak rock masses, enhancing structural integrity and safety. Roof bolters focus on the immediate roof of mining entries, installing roof bolts to support overhead rock layers and maintain tunnel stability during excavation activities.

Key Responsibilities: Rock Bolter vs Roof Bolter

Rock bolters specialize in installing rock reinforcement systems to stabilize underground mine walls and prevent rock falls, focusing on drilling, placing rock bolts, and ensuring structural integrity. Roof bolters primarily secure the overhead rock strata by drilling holes and inserting support bolts to maintain roof stability and protect miners from collapses. Both roles require precision in bolt placement and maintenance of mining safety standards, with rock bolters targeting lateral rock mass and roof bolters concentrating on the mine ceiling.

Required Skills and Qualifications

Rock Bolters require expertise in handling heavy drilling machinery and knowledge of rock mechanics to ensure safe and precise installation of bolts in underground mining operations. Roof Bolters must possess skills in operating specialized bolting equipment, understanding geological formations, and adhering to stringent safety protocols for roof reinforcement. Both roles demand mechanical aptitude, familiarity with mining regulations, and the ability to perform physical labor in confined spaces.

Equipment and Technologies Used

Rock bolters and roof bolters are essential mining equipment designed to enhance underground stability by anchoring rock layers. Rock bolters typically use mechanical or resin anchor systems powered by hydraulic or pneumatic drills, whereas roof bolters often incorporate automated drilling rigs with advanced dust suppression and real-time monitoring technologies. Both machines employ innovative torque control and sensor integration to optimize bolt installation, ensuring safety and operational efficiency in underground mining environments.

Safety Protocols and Procedures

Rock bolters and roof bolters require stringent safety protocols to prevent rock falls and structural collapses in underground mining environments. Proper training on equipment handling, routine inspections, and the use of personal protective equipment (PPE) reduce the risk of accidents during bolting operations. Adherence to established procedures, such as securing loose material prior to bolting and monitoring bolt integrity, enhances the overall safety of mine workers.

Typical Work Environments

Rock bolters are primarily used in underground mining operations where they stabilize rock formations in tunnels and shafts, often working in confined and unstable rock faces. Roof bolters are specifically designed for securing the overhead rock layers in underground coal mines and hard rock mines, functioning in environments requiring precise overhead support to prevent roof falls. Both machines operate in hazardous conditions demanding strict safety protocols and trained operators to ensure structural integrity and worker safety.

Training and Certification Requirements

Rock bolters and roof bolters in mining require specialized training focused on equipment operation, safety protocols, and hazard recognition specific to underground environments. Certification programs typically mandate hands-on instruction, competency assessments, and compliance with Mine Safety and Health Administration (MSHA) standards for both types of bolters. Employers often require continuous education and recertification to ensure up-to-date knowledge on new technologies and safety regulations.

Daily Challenges and Problem-Solving

Rock bolters in mining face daily challenges such as uneven rock surfaces and varying rock hardness, requiring adaptive drilling techniques to ensure secure stabilization. Roof bolters confront issues like confined working spaces and roof irregularities, necessitating precise positioning and reliable bolt installation to prevent collapses. Both machines demand regular maintenance and operator skill to efficiently address equipment wear and unexpected geological conditions.

Career Pathways and Advancement

Rock Bolters typically begin in entry-level mining roles, gaining hands-on experience with drilling and rock reinforcement techniques before advancing to supervisory positions. Roof Bolters often follow a career path emphasizing safety management and equipment operation, progressing from operator to safety specialist or maintenance supervisor. Both careers offer opportunities for advancement into mining engineering or site management, with strong emphasis on technical skills and safety certifications.

Industry Demand and Job Outlook

The demand for Rock Bolters remains strong in underground mining operations due to their efficiency in stabilizing rock formations and preventing collapses, which is critical for worker safety. Roof Bolters are increasingly sought after as mining companies invest in automation and advanced bolting technology to enhance operational efficiency and reduce downtime. Job outlook for both positions shows steady growth, driven by expansion in mineral extraction projects and the need for improved safety standards in mines worldwide.

Rock Bolter vs Roof Bolter Infographic

jobdiv.com

jobdiv.com