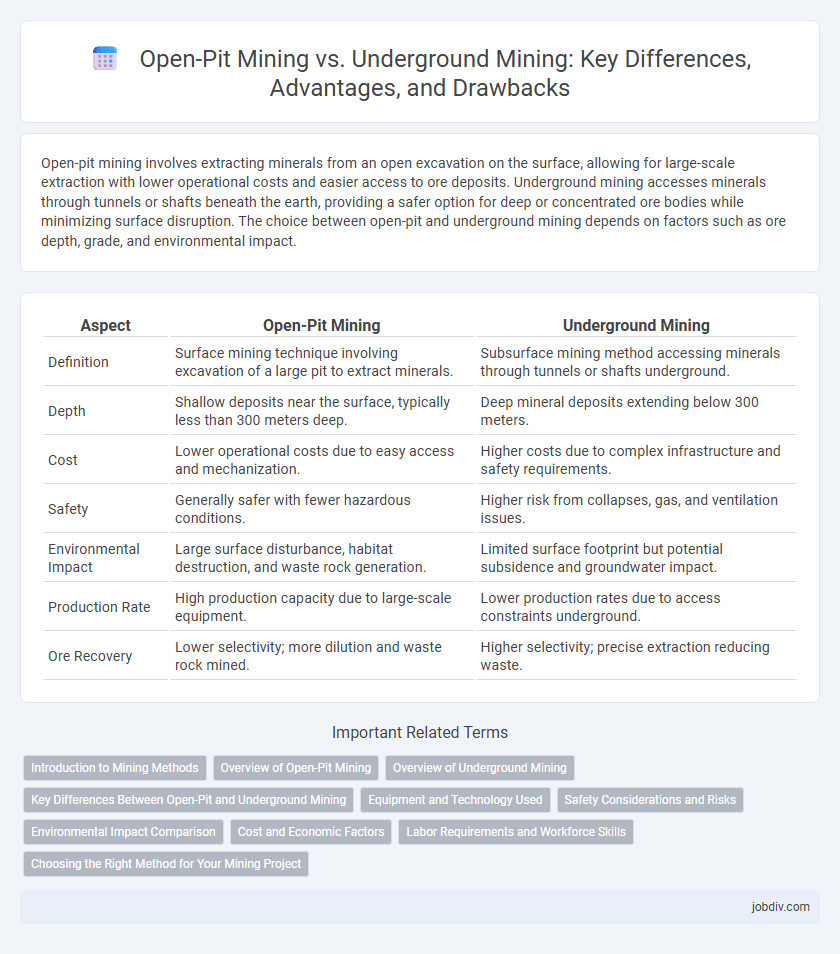

Open-pit mining involves extracting minerals from an open excavation on the surface, allowing for large-scale extraction with lower operational costs and easier access to ore deposits. Underground mining accesses minerals through tunnels or shafts beneath the earth, providing a safer option for deep or concentrated ore bodies while minimizing surface disruption. The choice between open-pit and underground mining depends on factors such as ore depth, grade, and environmental impact.

Table of Comparison

| Aspect | Open-Pit Mining | Underground Mining |

|---|---|---|

| Definition | Surface mining technique involving excavation of a large pit to extract minerals. | Subsurface mining method accessing minerals through tunnels or shafts underground. |

| Depth | Shallow deposits near the surface, typically less than 300 meters deep. | Deep mineral deposits extending below 300 meters. |

| Cost | Lower operational costs due to easy access and mechanization. | Higher costs due to complex infrastructure and safety requirements. |

| Safety | Generally safer with fewer hazardous conditions. | Higher risk from collapses, gas, and ventilation issues. |

| Environmental Impact | Large surface disturbance, habitat destruction, and waste rock generation. | Limited surface footprint but potential subsidence and groundwater impact. |

| Production Rate | High production capacity due to large-scale equipment. | Lower production rates due to access constraints underground. |

| Ore Recovery | Lower selectivity; more dilution and waste rock mined. | Higher selectivity; precise extraction reducing waste. |

Introduction to Mining Methods

Open-pit mining involves extracting minerals from an open excavation on the surface, ideal for large, near-surface ore bodies with lower operational costs and higher safety compared to underground methods. Underground mining targets deeper ore deposits, utilizing tunnels and shafts to access minerals while minimizing surface disturbance and allowing extraction of high-grade ores. Selecting between open-pit and underground mining depends on ore depth, grade, geology, and economic factors, influencing equipment choice, environmental impact, and operational efficiency.

Overview of Open-Pit Mining

Open-pit mining involves extracting minerals from an open excavation or borrow pit on the surface, allowing access to large ore bodies near the surface with minimal overburden removal. This method is highly efficient for mining resources like copper, iron, gold, and coal, enabling economies of scale and facilitating easier transportation of ore. Environmental considerations include landscape disruption and waste rock management, but advanced reclamation techniques help mitigate impacts.

Overview of Underground Mining

Underground mining involves extracting minerals from deep beneath the earth's surface using tunnels and shafts, enabling access to ore deposits that are not economically feasible to mine by open-pit methods. This technique minimizes surface disturbance and is often essential for minerals located at great depths or beneath urban areas. Key methods include room-and-pillar, cut-and-fill, and block caving, each selected based on geology, ore body shape, and economic factors.

Key Differences Between Open-Pit and Underground Mining

Open-pit mining involves extracting minerals from an open excavation on the surface, offering easier access to ore bodies and allowing the use of large machinery, making it cost-effective for shallow deposits. Underground mining accesses deeper mineral deposits through tunnels or shafts, minimizing surface environmental impact but requiring complex ventilation and safety systems. The choice between these methods depends on deposit depth, ore grade, and environmental considerations, influencing operational costs and extraction efficiency.

Equipment and Technology Used

Open-pit mining utilizes large-scale equipment such as electric shovels, haul trucks, and drills designed for surface extraction, alongside advanced GPS and real-time data tracking systems to enhance operational efficiency. Underground mining relies on specialized machinery like continuous miners, longwall shearers, and roof bolters, integrated with ventilation control technologies and remote monitoring systems to ensure safety and productivity in confined spaces. Both methods increasingly incorporate automation and IoT-enabled devices to optimize ore extraction and reduce operational costs.

Safety Considerations and Risks

Open-pit mining presents higher risks of slope failures, rock falls, and equipment accidents, requiring extensive safety barriers, monitoring systems, and proper ventilation to mitigate hazards. Underground mining involves dangers such as cave-ins, gas explosions, and limited escape routes, necessitating rigorous air quality control, structural support, and emergency response plans. Both methods demand strict adherence to safety regulations, continuous risk assessments, and worker training to minimize incidents and protect miner health.

Environmental Impact Comparison

Open-pit mining generates significant surface disturbance, deforestation, and habitat destruction, leading to increased soil erosion and water contamination from exposed tailings and chemicals. Underground mining minimizes surface footprint but risks subsidence and groundwater pollution through acid mine drainage. Both methods require extensive remediation efforts, but underground mining generally results in less visible environmental degradation compared to the expansive land disruption caused by open-pit operations.

Cost and Economic Factors

Open-pit mining generally incurs lower operational costs due to easier access to ore and higher production rates, making it more economically viable for large, near-surface deposits. Underground mining involves higher expenses from complex infrastructure, ventilation, and safety measures, increasing the overall cost per ton of extracted material. Economic feasibility depends on ore grade, depth, and market prices, with open-pit favored for shallow deposits and underground preferred for deeper, high-grade ores.

Labor Requirements and Workforce Skills

Open-pit mining demands a larger workforce with skills in heavy machinery operation and surface mining techniques, prioritizing efficiency in large-scale excavation. Underground mining requires a smaller, highly specialized labor force proficient in tunneling, ventilation management, and safety protocols due to confined working environments. Workforce training intensity and safety expertise significantly differ, with underground mining emphasizing advanced technical skills and hazard mitigation.

Choosing the Right Method for Your Mining Project

Selecting the appropriate mining method hinges on ore depth, geologic conditions, and economic factors; open-pit mining is optimal for shallow, expansive ore bodies allowing cost-effective extraction, while underground mining suits deeper, concentrated deposits requiring minimal surface disruption. Considerations include ore grade, environmental impact, safety risks, and operational costs, which influence project feasibility and profitability. Leveraging advanced geological surveys and economic modeling guides the decision-making process, ensuring alignment with project goals and regulatory compliance.

Open-Pit Mining vs Underground Mining Infographic

jobdiv.com

jobdiv.com