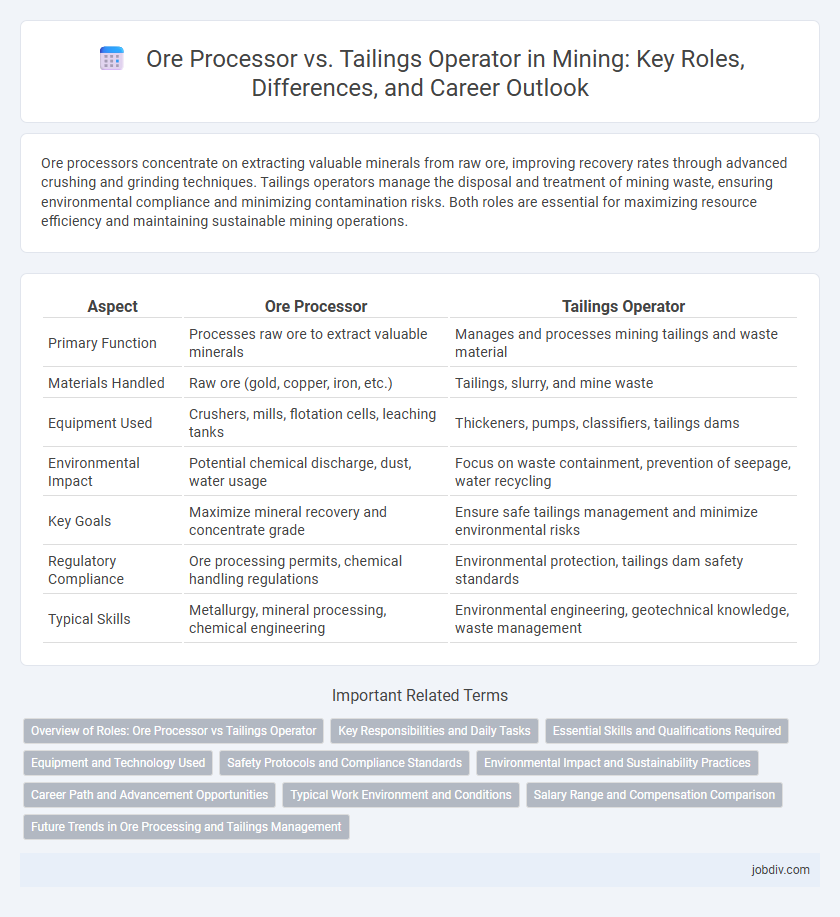

Ore processors concentrate on extracting valuable minerals from raw ore, improving recovery rates through advanced crushing and grinding techniques. Tailings operators manage the disposal and treatment of mining waste, ensuring environmental compliance and minimizing contamination risks. Both roles are essential for maximizing resource efficiency and maintaining sustainable mining operations.

Table of Comparison

| Aspect | Ore Processor | Tailings Operator |

|---|---|---|

| Primary Function | Processes raw ore to extract valuable minerals | Manages and processes mining tailings and waste material |

| Materials Handled | Raw ore (gold, copper, iron, etc.) | Tailings, slurry, and mine waste |

| Equipment Used | Crushers, mills, flotation cells, leaching tanks | Thickeners, pumps, classifiers, tailings dams |

| Environmental Impact | Potential chemical discharge, dust, water usage | Focus on waste containment, prevention of seepage, water recycling |

| Key Goals | Maximize mineral recovery and concentrate grade | Ensure safe tailings management and minimize environmental risks |

| Regulatory Compliance | Ore processing permits, chemical handling regulations | Environmental protection, tailings dam safety standards |

| Typical Skills | Metallurgy, mineral processing, chemical engineering | Environmental engineering, geotechnical knowledge, waste management |

Overview of Roles: Ore Processor vs Tailings Operator

Ore Processors handle the extraction and initial treatment of valuable minerals from raw ore, utilizing crushing, grinding, and chemical processes to maximize metal yield. Tailings Operators manage the disposal and containment of waste materials leftover after mineral extraction, ensuring environmental compliance and safe storage through tailings dams and filtration systems. Both roles are critical in mining operations, with Ore Processors focused on resource recovery and Tailings Operators dedicated to sustainable waste management.

Key Responsibilities and Daily Tasks

Ore processors specialize in extracting valuable minerals by operating crushing, grinding, and separation equipment to ensure optimal metal recovery. Tailings operators manage the disposal and treatment of mining waste, monitoring tailings ponds to prevent environmental contamination and maintain regulatory compliance. Both roles require constant equipment inspection, sample analysis, and coordination with safety protocols to maximize efficiency and minimize environmental impact.

Essential Skills and Qualifications Required

Ore processors require strong knowledge of mineralogy, crushing and grinding techniques, and proficiency in operating heavy machinery with precision for optimal ore extraction. Tailings operators must possess expertise in environmental safety protocols, waste management, and skillful handling of tailings disposal systems to prevent ecological contamination. Both roles demand attention to detail, mechanical aptitude, and compliance with mining regulations and safety standards.

Equipment and Technology Used

Ore processors utilize crushing mills, gravity separators, and flotation cells to extract valuable minerals efficiently, focusing on maximizing ore recovery through advanced sensor-based sorting and automation technologies. Tailings operators employ thickening tanks, filtration systems, and water treatment plants to manage and recycle mining residues, integrating real-time monitoring and geotechnical instruments to ensure environmental compliance and tailings dam stability. Equipment upgrades in both roles emphasize digital integration, such as IoT-enabled machinery and AI-driven process optimization, enhancing operational safety and productivity.

Safety Protocols and Compliance Standards

Ore processors and tailings operators both adhere to strict safety protocols and compliance standards to minimize workplace hazards and environmental impact. Ore processors focus on managing high-risk activities related to crushing, grinding, and chemical treatment of ore, requiring rigorous personal protective equipment (PPE) use and monitoring of dust and chemical exposure. Tailings operators prioritize containment and stability of waste materials, enforcing stringent procedures for dam safety, water treatment, and continuous environmental monitoring to prevent spills and contamination.

Environmental Impact and Sustainability Practices

Ore processors play a significant role in minimizing environmental impact by efficiently extracting valuable minerals, reducing waste generation, and enabling resource recovery through advanced technologies like flotation and bioleaching. Tailings operators focus on managing and stabilizing mining waste by implementing sustainable practices such as dry stacking, reprocessing tailings for residual metals, and ensuring containment to prevent soil and water contamination. Both roles are critical in promoting sustainable mining operations by reducing ecological footprint and enhancing resource optimization.

Career Path and Advancement Opportunities

Ore Processors typically start their careers handling raw materials and operating crushing, grinding, and separating machinery, gaining technical expertise in mineral extraction and processing techniques. Tailings Operators specialize in managing and monitoring waste materials from mining operations, focusing on environmental compliance, waste management, and rehabilitation processes, which often leads to roles in environmental management or regulatory affairs. Career advancement for Ore Processors often progresses towards senior technical positions or process optimization roles, while Tailings Operators can advance into environmental supervision, sustainability coordination, or regulatory compliance management within the mining sector.

Typical Work Environment and Conditions

Ore processors typically work in controlled industrial settings within processing plants where they manage crushers, grinders, and flotation cells under strict safety protocols to handle ore extraction efficiently. Tailings operators are often situated near tailings storage facilities, exposed to outdoor conditions with potential dust, moisture, and varying weather, requiring vigilance to maintain environmental safety and prevent contamination. Both roles demand adherence to regulatory standards and the use of personal protective equipment to mitigate occupational hazards in mining operations.

Salary Range and Compensation Comparison

Ore Processors typically earn between $45,000 and $70,000 annually, reflecting the technical skill required to extract valuable minerals from raw ore. Tailings Operators generally have a salary range of $40,000 to $65,000, focusing on managing waste materials from mining operations to ensure environmental compliance. Compensation packages for Ore Processors often include performance bonuses and hazard pay due to the intensive nature of ore extraction, whereas Tailings Operators may receive additional benefits linked to environmental stewardship and safety protocols.

Future Trends in Ore Processing and Tailings Management

Future trends in ore processing emphasize automation and advanced sensor technologies to enhance recovery rates and reduce energy consumption, while tailings management increasingly adopts sustainable practices such as dry stacking and real-time monitoring to minimize environmental impact. Digital twins and AI-driven predictive maintenance are transforming both ore processors and tailings operators by optimizing operational efficiency and safety. The integration of circular economy principles drives innovation in resource recovery from tailings, highlighting an industry shift toward zero-waste mining operations.

Ore Processor vs Tailings Operator Infographic

jobdiv.com

jobdiv.com