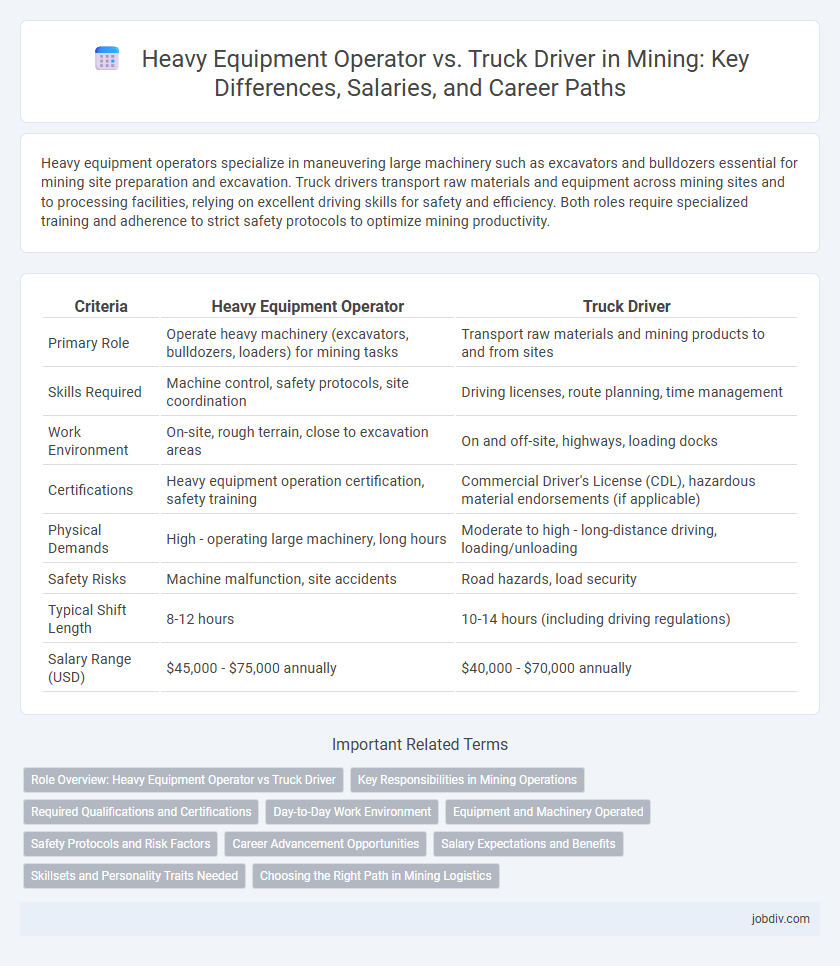

Heavy equipment operators specialize in maneuvering large machinery such as excavators and bulldozers essential for mining site preparation and excavation. Truck drivers transport raw materials and equipment across mining sites and to processing facilities, relying on excellent driving skills for safety and efficiency. Both roles require specialized training and adherence to strict safety protocols to optimize mining productivity.

Table of Comparison

| Criteria | Heavy Equipment Operator | Truck Driver |

|---|---|---|

| Primary Role | Operate heavy machinery (excavators, bulldozers, loaders) for mining tasks | Transport raw materials and mining products to and from sites |

| Skills Required | Machine control, safety protocols, site coordination | Driving licenses, route planning, time management |

| Work Environment | On-site, rough terrain, close to excavation areas | On and off-site, highways, loading docks |

| Certifications | Heavy equipment operation certification, safety training | Commercial Driver's License (CDL), hazardous material endorsements (if applicable) |

| Physical Demands | High - operating large machinery, long hours | Moderate to high - long-distance driving, loading/unloading |

| Safety Risks | Machine malfunction, site accidents | Road hazards, load security |

| Typical Shift Length | 8-12 hours | 10-14 hours (including driving regulations) |

| Salary Range (USD) | $45,000 - $75,000 annually | $40,000 - $70,000 annually |

Role Overview: Heavy Equipment Operator vs Truck Driver

Heavy Equipment Operators in mining control large machinery such as excavators, bulldozers, and loaders to excavate, move, and manage earth and materials efficiently on-site. Truck Drivers specialize in transporting ore, minerals, and equipment between mining sites and processing facilities, ensuring timely and safe delivery while navigating challenging terrain. Both roles are critical to mining operations, with Heavy Equipment Operators focusing on material handling and site preparation, while Truck Drivers emphasize logistics and supply chain continuity.

Key Responsibilities in Mining Operations

Heavy equipment operators in mining are responsible for operating machinery such as excavators, bulldozers, and loaders to extract and move materials efficiently. Truck drivers specialize in transporting mined materials from extraction sites to processing plants or stockpiles, ensuring timely and safe delivery. Both roles require adherence to safety protocols and coordination with site supervisors to maintain operational flow in mining operations.

Required Qualifications and Certifications

Heavy equipment operators in mining must hold certifications such as a Commercial Driver's License (CDL) with specialized endorsements and OSHA safety training, while truck drivers require a CDL with a focus on hauling heavy loads and hazardous materials endorsements. Operators often need technical training in machinery operation, including bulldozers, excavators, and loaders, alongside knowledge of mining site safety protocols. Truck drivers must demonstrate expertise in vehicle maintenance, route planning, and compliance with Department of Transportation (DOT) regulations for transporting mined materials.

Day-to-Day Work Environment

Heavy equipment operators in mining manage machinery such as excavators, bulldozers, and loaders, working directly on-site to move earth and extract materials in often challenging terrain and weather conditions. Truck drivers handle the transportation of mined materials, operating large haul trucks over long distances within and outside the mine, requiring focus on safety, vehicle maintenance, and adherence to schedules. Both roles demand physical endurance and strict compliance with mining safety protocols, but operators are more engaged in technical machine operation while drivers prioritize logistical efficiency and road navigation.

Equipment and Machinery Operated

Heavy equipment operators in mining manage machinery such as excavators, bulldozers, and loaders essential for earthmoving, drilling, and site preparation. Truck drivers operate haul trucks and dump trucks designed for transporting ore, minerals, and materials across mining sites and processing plants. The distinction lies in the operation of stationary or mobile equipment for extraction versus vehicles focused on material transport within the mining workflow.

Safety Protocols and Risk Factors

Heavy Equipment Operators and Truck Drivers in mining both adhere to rigorous safety protocols, including mandatory personal protective equipment (PPE), regular equipment inspections, and adherence to site-specific hazard controls to mitigate risks. Operators face risks such as equipment rollovers, entrapment, and mechanical failures, while Truck Drivers encounter hazards like fatigue-induced errors, load shifts, and high-impact collisions during transport. Comprehensive training programs and real-time monitoring systems are critical in reducing incidents and ensuring compliance with Occupational Safety and Health Administration (OSHA) guidelines and mining safety standards.

Career Advancement Opportunities

Heavy Equipment Operators in mining often have clearer paths to supervisory or specialized technical roles due to the complexity of machinery operated, leading to opportunities in equipment maintenance management and project coordination. Truck Drivers in mining primarily advance through logistics management or fleet supervision by gaining experience in route optimization and safety compliance. Career advancement for both roles depends on acquiring certifications, safety training, and operational expertise within the mining industry.

Salary Expectations and Benefits

Heavy equipment operators in mining typically earn an average salary between $55,000 and $80,000 annually, reflecting specialized skills in handling machinery such as excavators and bulldozers. Truck drivers in mining, particularly those operating haul trucks, generally have salary expectations ranging from $50,000 to $75,000 per year, with potential incentives for overtime and long-haul routes. Both roles often receive comprehensive benefits packages including health insurance, retirement plans, and paid leave, though heavy equipment operators may have access to higher bonuses due to the technical nature of their work.

Skillsets and Personality Traits Needed

Heavy Equipment Operators in mining require technical proficiency in operating machinery such as excavators, bulldozers, and loaders, along with spatial awareness for precise maneuvering in challenging terrains. Truck Drivers need strong navigation skills, endurance for long haul routes, and the ability to manage heavy loads safely while adhering to regulations. Both roles demand high attention to safety protocols, quick decision-making, and adaptability to dynamic mining site conditions, but Heavy Equipment Operators typically exhibit more mechanical aptitude, whereas Truck Drivers show greater stamina and route-planning expertise.

Choosing the Right Path in Mining Logistics

Heavy equipment operators and truck drivers play critical roles in mining logistics, with operators handling machinery like excavators and loaders for material extraction, while truck drivers specialize in transporting these materials across sites and to processing facilities. Selecting the right path depends on one's skills and interest in either operating complex machinery or focusing on efficient and safe transportation within mining environments. Understanding job demands, safety protocols, and certification requirements for heavy equipment operation versus commercial trucking licenses can guide career decisions in the mining logistics sector.

Heavy Equipment Operator vs Truck Driver Infographic

jobdiv.com

jobdiv.com