Underground mining involves extracting minerals from deep beneath the earth's surface through tunnels and shafts, allowing access to resources that are not feasible to reach via surface mining. Open-pit mining, in contrast, excavates large surface holes to access ore deposits closer to the surface, offering a more cost-effective and safer method for minerals spread over a wide area. While underground mining minimizes surface disturbance and environmental impact, open-pit mining enables higher production rates and easier mechanization.

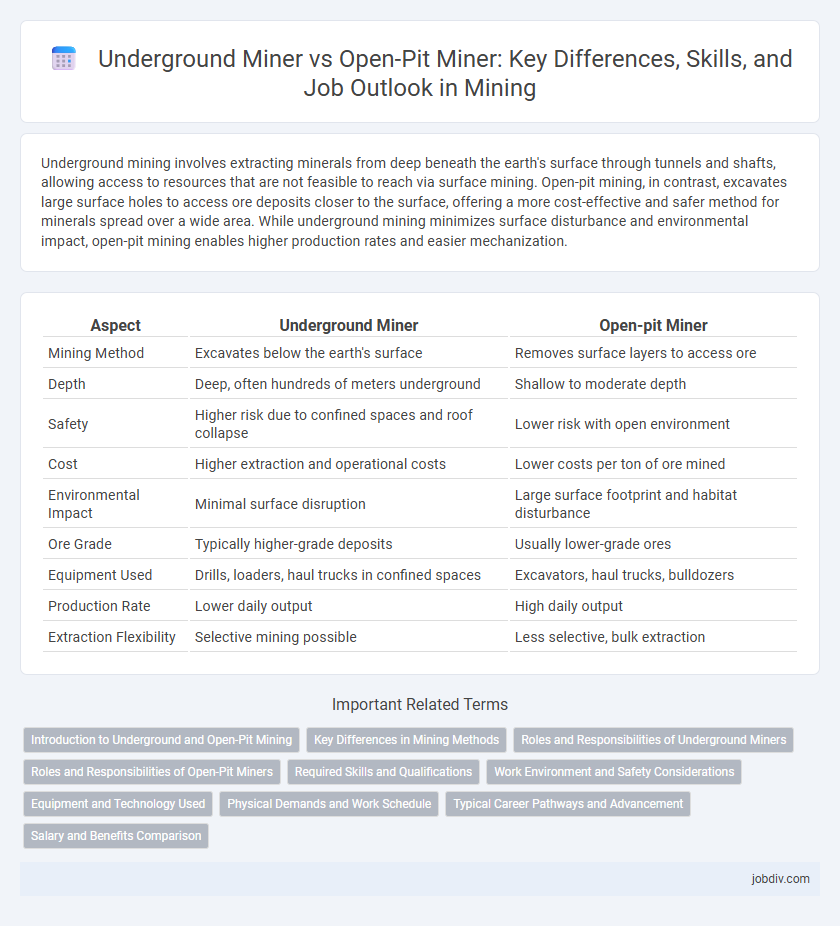

Table of Comparison

| Aspect | Underground Miner | Open-pit Miner |

|---|---|---|

| Mining Method | Excavates below the earth's surface | Removes surface layers to access ore |

| Depth | Deep, often hundreds of meters underground | Shallow to moderate depth |

| Safety | Higher risk due to confined spaces and roof collapse | Lower risk with open environment |

| Cost | Higher extraction and operational costs | Lower costs per ton of ore mined |

| Environmental Impact | Minimal surface disruption | Large surface footprint and habitat disturbance |

| Ore Grade | Typically higher-grade deposits | Usually lower-grade ores |

| Equipment Used | Drills, loaders, haul trucks in confined spaces | Excavators, haul trucks, bulldozers |

| Production Rate | Lower daily output | High daily output |

| Extraction Flexibility | Selective mining possible | Less selective, bulk extraction |

Introduction to Underground and Open-Pit Mining

Underground mining involves extracting minerals from deep beneath the Earth's surface through tunnels and shafts, allowing access to ore bodies that are not economically viable to reach via surface methods. Open-pit mining, by contrast, removes large quantities of surface soil and rock to expose ore deposits near the surface, enabling efficient extraction with heavy machinery. Both methods require extensive geological surveying and planning to optimize resource recovery while managing environmental impact and operational costs.

Key Differences in Mining Methods

Underground mining involves extracting minerals through tunnels or shafts beneath the earth's surface, targeting deep-seated ore deposits with minimal surface impact. Open-pit mining extracts minerals from a large, open excavation at the surface, ideal for shallow, massive ore bodies but causing significant landscape alteration. Key differences include depth of operation, environmental footprint, and equipment used, with underground mining offering higher precision and safety challenges, while open-pit mining emphasizes volume and cost-efficiency.

Roles and Responsibilities of Underground Miners

Underground miners specialize in extracting minerals from deep beneath the earth's surface, operating within tunnels and shafts to access ore deposits that are inaccessible to open-pit miners. Their roles include drilling, blasting, and transporting ore while ensuring structural safety and ventilation to prevent hazardous conditions. These miners must also monitor ground stability, maintain equipment, and follow strict safety protocols to mitigate risks associated with confined spaces and potential underground hazards.

Roles and Responsibilities of Open-Pit Miners

Open-pit miners manage large surface excavations, extracting minerals by removing overburden and drilling, blasting, loading, and hauling ore efficiently. Their responsibilities include operating heavy machinery such as excavators, haul trucks, and drills, ensuring strict adherence to safety protocols and environmental regulations. Open-pit miners also monitor geological data to optimize extraction processes and maintain cost-effective mining operations.

Required Skills and Qualifications

Underground miners require specialized training in confined space navigation, ventilation systems, and safety protocols due to the high-risk subterranean environment, often holding certifications in mine rescue and hazardous materials handling. Open-pit miners need expertise in heavy machinery operation, earthmoving equipment, and surface surveying techniques, with qualifications frequently including mechanical skills and knowledge of environmental regulations. Both roles demand physical stamina, adherence to safety standards, and experience with mining software for site planning and resource extraction optimization.

Work Environment and Safety Considerations

Underground miners operate in confined, dark tunnels with higher risks of roof collapses, gas leaks, and limited ventilation, necessitating stringent safety measures and continuous monitoring. Open-pit miners work in exposed environments where hazards include heavy machinery accidents, dust, and extreme weather conditions, requiring comprehensive protective equipment and dust control systems. Both environments demand specialized training and protocols to mitigate the inherent safety risks unique to each mining method.

Equipment and Technology Used

Underground mining employs specialized equipment such as continuous miners, shuttle cars, and roof bolters designed for confined spaces and precise excavation, whereas open-pit mining utilizes large-scale machinery including draglines, bucket-wheel excavators, and haul trucks optimized for extracting surface deposits. Advanced technologies like automated drilling systems and remote-controlled vehicles enhance safety and efficiency underground, while GPS-guided equipment and real-time data analytics improve the operational accuracy and productivity in open-pit mining. Both mining methods integrate ventilation control and environmental monitoring systems, tailored to their specific operational challenges and equipment requirements.

Physical Demands and Work Schedule

Underground miners face intense physical demands such as maneuvering in confined spaces, handling heavy equipment, and enduring high humidity and low ventilation, often working in shifts lasting 8 to 12 hours. Open-pit miners experience strenuous labor involving continuous exposure to weather conditions, operating large machinery, and performing repetitive tasks, with work schedules typically from 10 to 12-hour day shifts. Both roles require stamina and adaptability, but underground mining frequently poses greater risks due to adverse environmental factors and irregular airflow.

Typical Career Pathways and Advancement

Underground miners often begin as laborers or helpers, advancing through roles like shotfirer, driller, and shift supervisor due to specialized skills in confined, hazardous environments. Open-pit miners typically start as heavy equipment operators or truck drivers, progressing to site supervisor and mine manager positions, leveraging expertise in large-scale surface extraction and equipment management. Career advancement in both fields depends on technical certifications, experience, and leadership abilities, with underground mining requiring more intensive safety and operational training.

Salary and Benefits Comparison

Underground miners typically earn higher salaries than open-pit miners due to the increased risks and technical skills required for subterranean operations, with average annual wages ranging from $60,000 to $90,000 compared to $50,000 to $75,000 for open-pit miners. Benefits for underground miners often include comprehensive health insurance, hazard pay, and additional safety bonuses reflecting the demanding work environment, while open-pit miners may have more standard benefit packages but often receive performance-based incentives. The variance in compensation aligns closely with the complexity, safety risks, and physical demands inherent to each mining method.

Underground Miner vs Open-pit Miner Infographic

jobdiv.com

jobdiv.com