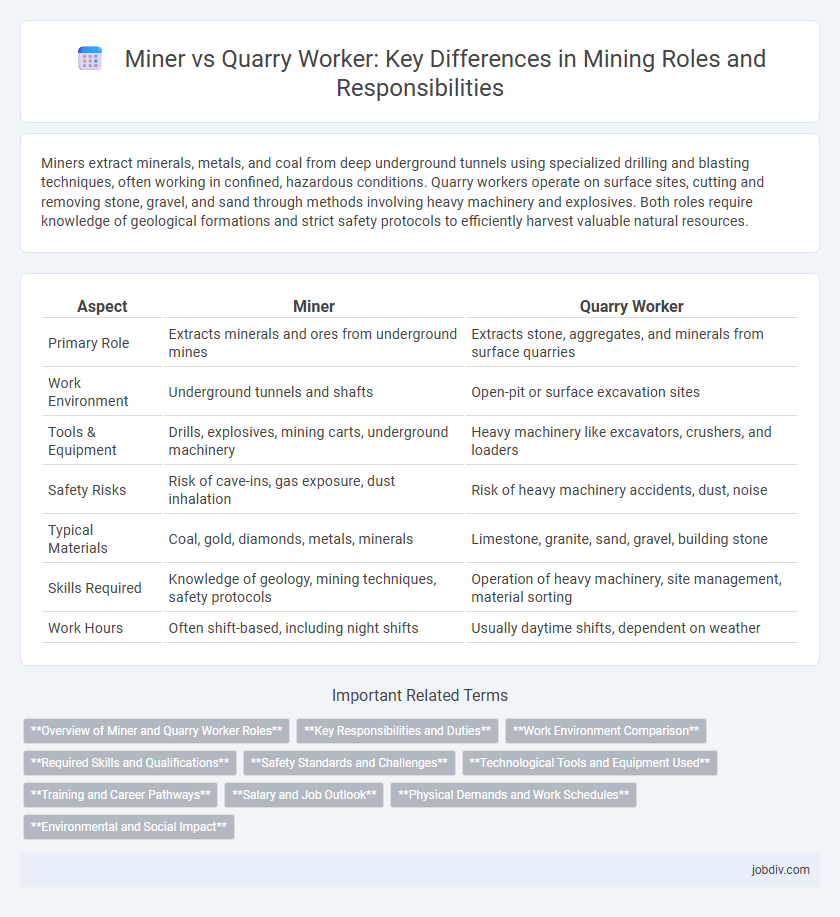

Miners extract minerals, metals, and coal from deep underground tunnels using specialized drilling and blasting techniques, often working in confined, hazardous conditions. Quarry workers operate on surface sites, cutting and removing stone, gravel, and sand through methods involving heavy machinery and explosives. Both roles require knowledge of geological formations and strict safety protocols to efficiently harvest valuable natural resources.

Table of Comparison

| Aspect | Miner | Quarry Worker |

|---|---|---|

| Primary Role | Extracts minerals and ores from underground mines | Extracts stone, aggregates, and minerals from surface quarries |

| Work Environment | Underground tunnels and shafts | Open-pit or surface excavation sites |

| Tools & Equipment | Drills, explosives, mining carts, underground machinery | Heavy machinery like excavators, crushers, and loaders |

| Safety Risks | Risk of cave-ins, gas exposure, dust inhalation | Risk of heavy machinery accidents, dust, noise |

| Typical Materials | Coal, gold, diamonds, metals, minerals | Limestone, granite, sand, gravel, building stone |

| Skills Required | Knowledge of geology, mining techniques, safety protocols | Operation of heavy machinery, site management, material sorting |

| Work Hours | Often shift-based, including night shifts | Usually daytime shifts, dependent on weather |

Overview of Miner and Quarry Worker Roles

Miners extract valuable minerals and ores from underground or surface mines using specialized equipment and techniques to access and process raw materials. Quarry workers focus on extracting stone, gravel, and other construction aggregates from open-pit quarries, often involving heavy machinery and blasting methods. Both roles require knowledge of safety protocols, geology, and equipment operation but differ primarily in the materials handled and mining environments.

Key Responsibilities and Duties

Miners extract minerals, metals, and coal from underground or surface mines using specialized equipment and techniques to ensure safety and efficiency. Quarry workers focus on extracting stone, gravel, and sand from open pit quarries, operating heavy machinery for cutting, drilling, and transporting raw materials. Both roles require knowledge of geological formations and adherence to environmental and safety regulations to minimize risks and optimize resource recovery.

Work Environment Comparison

Miners typically work underground in confined, dark tunnels with limited ventilation and high risks of cave-ins and exposure to hazardous gases. Quarry workers operate in open-pit environments exposed to weather conditions, heavy machinery noise, and dust from rock blasting processes. Both professions demand strict safety measures, but the underground setting of miners poses unique challenges compared to the outdoor, surface-based work of quarry workers.

Required Skills and Qualifications

Miner roles demand proficiency in heavy machinery operation, knowledge of geological formations, and adherence to safety protocols, often requiring certifications in mining technology or engineering. Quarry workers must have skills in excavation, equipment maintenance, and materials handling, with qualifications typically including vocational training or experience in construction-related fields. Both occupations require physical stamina, problem-solving abilities, and compliance with occupational health and safety standards.

Safety Standards and Challenges

Miner safety standards require strict adherence to regulations like MSHA's 30 CFR Part 57, emphasizing air quality, roof support, and methane monitoring to prevent underground hazards. Quarry workers face challenges related to dust exposure, heavy machinery, and unstable rock faces, necessitating rigorous PPE use and continuous environmental monitoring. Both roles demand comprehensive training and emergency preparedness to mitigate the risks associated with falling debris, equipment accidents, and respiratory hazards.

Technological Tools and Equipment Used

Miners utilize advanced drilling machines, automated tunneling equipment, and remote-controlled loaders to extract minerals from underground deposits, enhancing safety and efficiency. Quarry workers operate heavy-duty machinery like stone crushers, excavators, and conveyor systems designed for surface extraction and material processing. Both professions increasingly rely on GPS technology, drones for site surveying, and real-time monitoring systems to optimize productivity and ensure worker safety.

Training and Career Pathways

Miner training typically involves specialized programs in underground or surface mining techniques, safety protocols, and equipment operation, often provided by trade schools or mining companies with apprenticeships. Quarry workers usually follow a career path starting with on-the-job training focused on stone extraction, machinery handling, and site maintenance, frequently supported by vocational training or certifications in heavy equipment operation. Both fields offer opportunities for advancement into supervisory or technical specialist roles through continuous education and hands-on experience.

Salary and Job Outlook

Miner salaries typically range from $45,000 to $70,000 annually, while quarry workers earn between $35,000 and $60,000, reflecting variations in skill level and geography. The job outlook for miners is projected to grow by 2% over the next decade due to increasing demand for minerals and energy resources. Quarry workers face a slightly slower growth rate of about 1%, influenced by mechanization and environmental regulations impacting quarry operations.

Physical Demands and Work Schedules

Miner roles require intense physical strength to handle heavy machinery and operate in confined, often hazardous underground environments, demanding stamina and resilience. Quarry workers engage in physically demanding tasks like drilling, blasting, and transporting large rocks in open-air settings, necessitating endurance and frequent heavy lifting. Miners typically work in shifts that may include nights and extended hours due to continuous underground operations, whereas quarry workers often follow more regular daytime schedules with occasional overtime depending on production needs.

Environmental and Social Impact

Miners often operate underground, minimizing surface disruption, whereas quarry workers extract materials from open pits, leading to significant landscape alteration and habitat loss. Quarrying typically generates higher levels of dust and noise pollution, negatively impacting nearby communities compared to most mining operations. Socially, quarry sites frequently cause displacement and reduce local land usability, while mining projects may foster more sustained economic development through employment and infrastructure.

Miner vs Quarry Worker Infographic

jobdiv.com

jobdiv.com