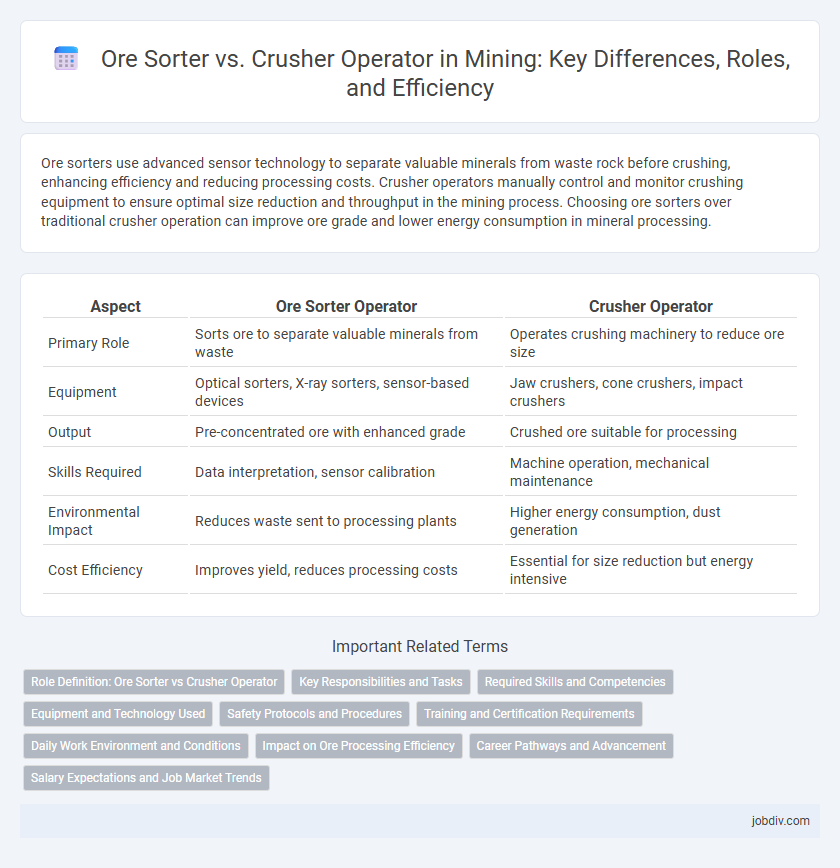

Ore sorters use advanced sensor technology to separate valuable minerals from waste rock before crushing, enhancing efficiency and reducing processing costs. Crusher operators manually control and monitor crushing equipment to ensure optimal size reduction and throughput in the mining process. Choosing ore sorters over traditional crusher operation can improve ore grade and lower energy consumption in mineral processing.

Table of Comparison

| Aspect | Ore Sorter Operator | Crusher Operator |

|---|---|---|

| Primary Role | Sorts ore to separate valuable minerals from waste | Operates crushing machinery to reduce ore size |

| Equipment | Optical sorters, X-ray sorters, sensor-based devices | Jaw crushers, cone crushers, impact crushers |

| Output | Pre-concentrated ore with enhanced grade | Crushed ore suitable for processing |

| Skills Required | Data interpretation, sensor calibration | Machine operation, mechanical maintenance |

| Environmental Impact | Reduces waste sent to processing plants | Higher energy consumption, dust generation |

| Cost Efficiency | Improves yield, reduces processing costs | Essential for size reduction but energy intensive |

Role Definition: Ore Sorter vs Crusher Operator

Ore sorters utilize advanced sensor-based technology to separate valuable minerals from waste rock, enhancing ore quality before processing. Crusher operators control and monitor machinery that breaks down large rocks into smaller, manageable pieces for further refinement in the mining process. The ore sorter role emphasizes precision and material discrimination, while crusher operators focus on mechanical operation and equipment maintenance.

Key Responsibilities and Tasks

Ore Sorters specialize in analyzing and separating valuable minerals from raw ore using advanced sensor-based technology to improve efficiency and reduce waste. Crusher Operators manage heavy machinery that crushes and processes raw materials into smaller, manageable sizes, ensuring consistent flow and safety compliance. Both roles are essential in optimizing mineral extraction; ore sorters focus on precision sorting, while crusher operators emphasize machinery operation and material size management.

Required Skills and Competencies

Ore Sorters require expertise in sensor technology, machine calibration, and material sorting accuracy to effectively separate valuable minerals from waste rock. Crusher Operators need strong mechanical aptitude, knowledge of crushing equipment operation, and the ability to monitor equipment performance to ensure efficient size reduction. Both roles demand attention to safety protocols, problem-solving skills, and the ability to perform routine maintenance to maximize mining productivity.

Equipment and Technology Used

Ore sorters employ advanced sensor technologies such as X-ray transmission, near-infrared, and laser-induced breakdown spectroscopy to separate valuable minerals from waste rock with high precision. Crusher operators manage heavy machinery like jaw crushers, cone crushers, and impact crushers that mechanically break down large rocks into smaller fragments suitable for processing. While ore sorters rely on automated, real-time data processing for selective sorting, crusher operators oversee robust mechanical equipment essential for downstream mineral extraction and processing workflows.

Safety Protocols and Procedures

Ore Sorter operators follow strict safety protocols including sensor calibration checks and maintaining clear communication with equipment control teams to prevent accidents. Crusher Operators adhere to procedural safeguards such as lockout/tagout processes, regular equipment inspections, and wearing mandatory personal protective equipment (PPE) to mitigate risks from moving components and material ejections. Both roles require compliance with environmental health regulations and ongoing safety training to ensure operational safety and reduce workplace hazards.

Training and Certification Requirements

Ore Sorter operators require specialized training in sensor-based sorting technologies and material flow management, often supplemented by certification programs specific to advanced optical or X-ray sorting equipment. Crusher operators must complete comprehensive safety and mechanical training, including certification in heavy machinery operation and adherence to regulatory standards for crushing plant safety. Both roles emphasize rigorous hands-on experience and continuous skill development to maintain operational efficiency and workplace safety in mining environments.

Daily Work Environment and Conditions

Ore Sorters primarily work in controlled environments near processing plants, managing advanced sensor equipment to separate valuable minerals from waste efficiently. Crusher Operators spend their shifts in noisy, dusty settings, monitoring and adjusting heavy machinery that breaks down raw ore into smaller pieces for further processing. Both roles require strict adherence to safety protocols, but Ore Sorters often experience less physical strain compared to the physically demanding and equipment-intensive conditions faced by Crusher Operators.

Impact on Ore Processing Efficiency

Ore sorters improve ore processing efficiency by accurately separating valuable minerals from waste rock before crushing, reducing the volume of material processed and lowering energy consumption. Crusher operators manage equipment that breaks down ore into smaller pieces, but processing inefficiencies can arise if low-grade material is fed into crushers. Combining ore sorting with effective crusher operation optimizes throughput, minimizes wear on crushing equipment, and increases overall recovery rates in mining operations.

Career Pathways and Advancement

Ore sorters specialize in advanced sensor-based technology to separate valuable minerals from waste, often requiring technical training in automation and data analysis. Crusher operators manage heavy machinery to break down ore into smaller fragments, gaining expertise in equipment maintenance and safety protocols. Career advancement for ore sorters often leads to roles in process optimization or mining technology, while crusher operators may progress to supervisory or machinery management positions.

Salary Expectations and Job Market Trends

Ore Sorter operators typically command higher salaries than crusher operators, with average annual wages ranging from $55,000 to $75,000, driven by the increasing adoption of advanced sorting technologies in mining. Crusher operators, earning between $45,000 and $60,000 annually, face a more saturated job market due to the automation of crushing processes and fewer specialized skill requirements. Job market trends indicate growing demand for technically skilled ore sorter operators as mines prioritize efficiency and ore quality, while crusher operator positions may decline or stabilize with incremental automation.

Ore Sorter vs Crusher Operator Infographic

jobdiv.com

jobdiv.com