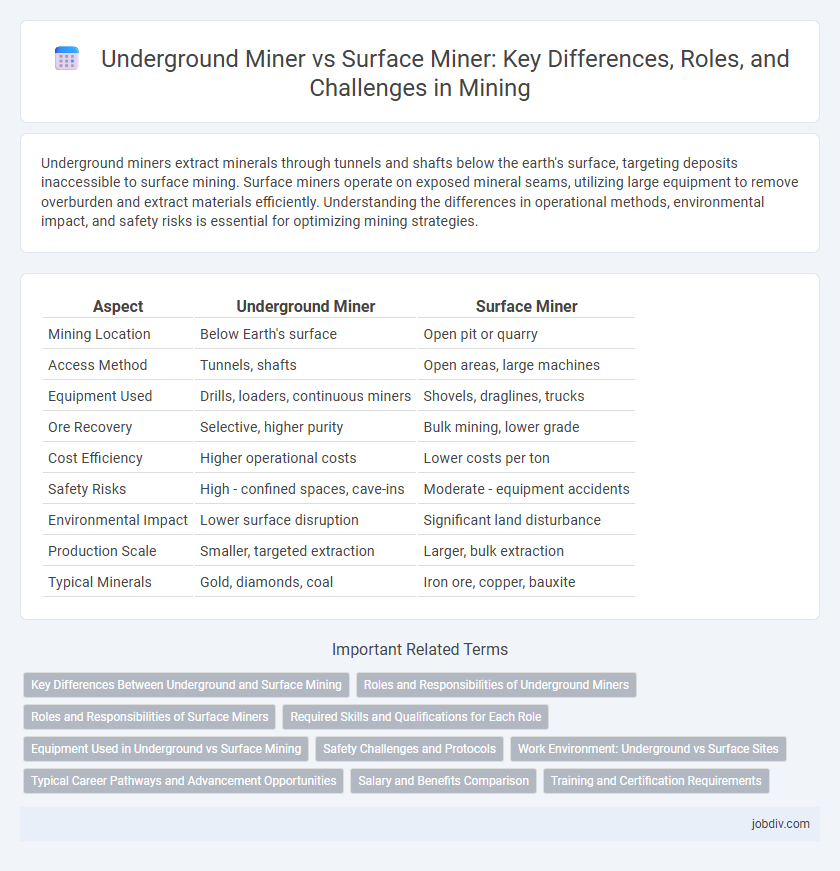

Underground miners extract minerals through tunnels and shafts below the earth's surface, targeting deposits inaccessible to surface mining. Surface miners operate on exposed mineral seams, utilizing large equipment to remove overburden and extract materials efficiently. Understanding the differences in operational methods, environmental impact, and safety risks is essential for optimizing mining strategies.

Table of Comparison

| Aspect | Underground Miner | Surface Miner |

|---|---|---|

| Mining Location | Below Earth's surface | Open pit or quarry |

| Access Method | Tunnels, shafts | Open areas, large machines |

| Equipment Used | Drills, loaders, continuous miners | Shovels, draglines, trucks |

| Ore Recovery | Selective, higher purity | Bulk mining, lower grade |

| Cost Efficiency | Higher operational costs | Lower costs per ton |

| Safety Risks | High - confined spaces, cave-ins | Moderate - equipment accidents |

| Environmental Impact | Lower surface disruption | Significant land disturbance |

| Production Scale | Smaller, targeted extraction | Larger, bulk extraction |

| Typical Minerals | Gold, diamonds, coal | Iron ore, copper, bauxite |

Key Differences Between Underground and Surface Mining

Underground mining involves extracting minerals from beneath the earth's surface through tunnels or shafts, allowing access to deep ore deposits, whereas surface mining removes overlying soil and rock to reach minerals near the surface. Key differences include operational costs, with underground mining typically being more expensive due to safety measures and ventilation requirements, while surface mining offers higher productivity and lower costs. Environmental impact varies as surface mining disrupts large land areas and ecosystems, whereas underground mining has a smaller surface footprint but poses risks like subsidence.

Roles and Responsibilities of Underground Miners

Underground miners specialize in extracting minerals from below the earth's surface, navigating confined tunnels and ensuring structural stability through roof support installation and ventilation management. Their responsibilities include operating drilling equipment, blasting rock with precise explosives placement, and transporting ore to surface processing areas while adhering to strict safety protocols. Unlike surface miners who manage large-scale excavation, underground miners focus on maintaining continuous communication and monitoring gas levels to prevent hazardous conditions in subterranean environments.

Roles and Responsibilities of Surface Miners

Surface miners operate heavy machinery to extract minerals from open-pit mines, focusing on efficient material removal and site safety. They manage equipment such as draglines, bucket-wheel excavators, and shovel loaders, ensuring optimal production rates and minimal environmental impact. Their responsibilities include monitoring surface conditions, conducting routine maintenance, and coordinating with blasting teams to maintain continuous workflow.

Required Skills and Qualifications for Each Role

Underground miners require expertise in confined space navigation, ventilation systems, and rock mechanics, often needing certifications in safety protocols like MSHA or equivalent. Surface miners prioritize skills in operating heavy machinery such as draglines and excavators, combined with knowledge of terrain analysis and environmental regulations. Both roles demand physical fitness, technical training, and a thorough understanding of mining safety standards to minimize risks and optimize productivity.

Equipment Used in Underground vs Surface Mining

Underground mining utilizes equipment such as continuous miners, longwall miners, shuttle cars, and roof bolters designed to operate in confined spaces and ensure miner safety. Surface mining relies on larger machinery like draglines, bucket-wheel excavators, bulldozers, and haul trucks capable of handling vast overburden removal and high-volume extraction. The equipment choice directly impacts operational efficiency, cost-effectiveness, and environmental footprint in mining projects.

Safety Challenges and Protocols

Underground mining presents unique safety challenges such as limited ventilation, risk of rock falls, and hazardous gas buildup, necessitating stringent protocols including continuous air quality monitoring, reinforced tunnel supports, and emergency evacuation plans. Surface mining involves exposure to extreme weather, heavy machinery accidents, and dust inhalation, requiring protocols like dust suppression systems, rigorous equipment maintenance, and comprehensive worker training. Both mining methods demand robust safety management systems tailored to their operational environments to minimize accidents and ensure worker protection.

Work Environment: Underground vs Surface Sites

Underground mining occurs in confined tunnels with limited ventilation and higher safety risks due to potential collapses and gas exposure, requiring specialized protective equipment and rigorous monitoring. Surface mining takes place in open environments with better air quality and natural light but often involves heavy machinery and dust generation, impacting worker health differently. The choice between underground and surface mining environments significantly affects operational strategies, safety protocols, and worker comfort.

Typical Career Pathways and Advancement Opportunities

Underground miners often start as entry-level laborers or equipment operators, advancing to roles such as shift supervisors, safety inspectors, or mine managers through experience and specialized training in confined environments. Surface miners typically begin as heavy machinery operators or drillers, progressing to positions like blasting specialists, site foremen, or operations managers with skills in open-pit or strip mining techniques. Both pathways offer opportunities for further advancement through certifications in mine safety, engineering, and geology, enhancing career growth in the mining industry.

Salary and Benefits Comparison

Underground miners typically earn higher salaries due to the hazardous working conditions and specialized skills required, with average wages ranging from $60,000 to $90,000 annually, compared to surface miners who earn between $45,000 and $70,000. Benefits for underground miners often include hazard pay, comprehensive health insurance, and retirement plans tailored to compensate for the physical risks, while surface miners usually receive standard health benefits and performance bonuses. Both roles may offer overtime pay and training programs, but underground mining positions generally present greater financial incentives linked to the job's complexity and safety challenges.

Training and Certification Requirements

Underground miners typically require specialized training focused on confined space safety, ventilation control, and emergency response, often mandated by regulatory bodies such as MSHA in the United States. Surface miners, on the other hand, undergo certification programs emphasizing equipment operation, environmental management, and hazard identification relevant to open-pit conditions. Both roles demand rigorous practical assessments and ongoing credential renewals to ensure compliance with regional mining safety standards.

Underground Miner vs Surface Miner Infographic

jobdiv.com

jobdiv.com