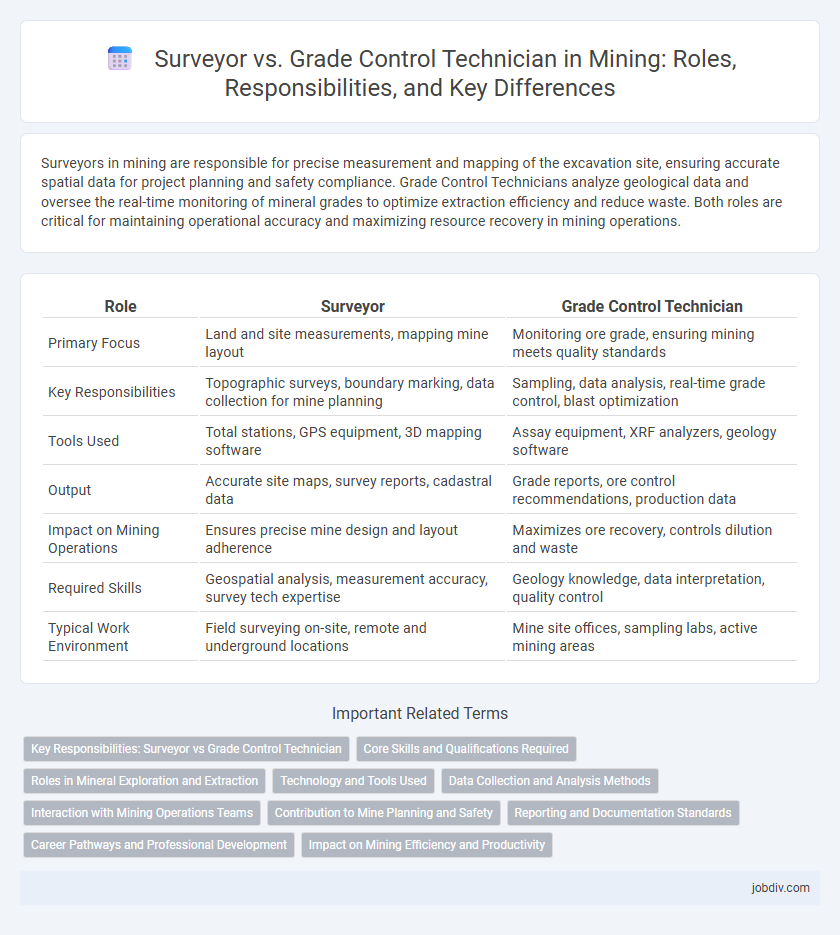

Surveyors in mining are responsible for precise measurement and mapping of the excavation site, ensuring accurate spatial data for project planning and safety compliance. Grade Control Technicians analyze geological data and oversee the real-time monitoring of mineral grades to optimize extraction efficiency and reduce waste. Both roles are critical for maintaining operational accuracy and maximizing resource recovery in mining operations.

Table of Comparison

| Role | Surveyor | Grade Control Technician |

|---|---|---|

| Primary Focus | Land and site measurements, mapping mine layout | Monitoring ore grade, ensuring mining meets quality standards |

| Key Responsibilities | Topographic surveys, boundary marking, data collection for mine planning | Sampling, data analysis, real-time grade control, blast optimization |

| Tools Used | Total stations, GPS equipment, 3D mapping software | Assay equipment, XRF analyzers, geology software |

| Output | Accurate site maps, survey reports, cadastral data | Grade reports, ore control recommendations, production data |

| Impact on Mining Operations | Ensures precise mine design and layout adherence | Maximizes ore recovery, controls dilution and waste |

| Required Skills | Geospatial analysis, measurement accuracy, survey tech expertise | Geology knowledge, data interpretation, quality control |

| Typical Work Environment | Field surveying on-site, remote and underground locations | Mine site offices, sampling labs, active mining areas |

Key Responsibilities: Surveyor vs Grade Control Technician

Surveyors in mining are primarily responsible for measuring and mapping mine sites, using GPS and total station equipment to ensure accurate spatial data that guides excavation and infrastructure placement. Grade Control Technicians focus on analyzing ore body data and providing precise instructions for blasting and excavation to maintain optimal ore quality and minimize dilution. Both roles collaborate to optimize mining operations by integrating topographical accuracy with real-time geological information.

Core Skills and Qualifications Required

Surveyors in mining require expertise in topographic mapping, land measurement, and GPS technology to accurately delineate site boundaries and ensure regulatory compliance. Grade Control Technicians must be proficient in geological interpretation, drill data analysis, and the use of specialized software like Datamine or Surpac to optimize ore extraction and maintain production targets. Both roles demand strong mathematical skills, attention to detail, and knowledge of mining safety regulations to effectively support mine planning and operations.

Roles in Mineral Exploration and Extraction

Surveyors in mineral exploration focus on mapping terrain and establishing precise boundaries to guide drilling and resource estimation, ensuring accurate spatial data acquisition. Grade Control Technicians analyze ore quality and distribution through sampling and real-time data processing, optimizing extraction by guiding mining operations to prioritize high-value material. Together, these roles enhance mining efficiency by combining spatial accuracy with ore quality assessment throughout the exploration and extraction phases.

Technology and Tools Used

Surveyors in mining primarily utilize GPS, total stations, and drone technology to create accurate topographic maps and ensure site layout precision. Grade Control Technicians rely on 3D modeling software, laser scanners, and real-time data systems to monitor ore body boundaries and optimize pit designs. Both roles integrate advanced geospatial and digital tools, enhancing operational efficiency and safety in mining projects.

Data Collection and Analysis Methods

Surveyors in mining utilize advanced GPS and total station equipment to collect precise spatial data for mapping and site planning, ensuring accurate topographical measurements. Grade Control Technicians employ laser scanning, sensor-equipped machinery, and real-time data collection tools to monitor ore boundaries and maintain excavation accuracy. Both roles analyze collected data using specialized software like GIS and mine modeling programs to optimize extraction processes and improve operational efficiency.

Interaction with Mining Operations Teams

Surveyors collaborate closely with mining operations teams by providing precise topographical data and boundary measurements essential for planning and design accuracy. Grade Control Technicians interact directly with drilling and blasting teams to ensure excavation follows exact grade specifications, optimizing ore recovery and minimizing waste. Both roles require seamless communication with equipment operators and geologists to maintain operational efficiency and safety standards.

Contribution to Mine Planning and Safety

Surveyors provide precise topographic data essential for creating accurate mine plans and ensuring boundaries are maintained, reducing risks of equipment collision and structural failures. Grade Control Technicians analyze ore boundaries and geology through sampling, directly impacting efficient extraction plans and minimizing dilution or ore loss. Their combined efforts optimize mine planning accuracy and enhance operational safety by preventing geotechnical hazards and ensuring compliance with design specifications.

Reporting and Documentation Standards

Surveyors in mining are responsible for precise spatial measurements and generating detailed topographic maps that comply with industry surveying standards and regulatory requirements. Grade Control Technicians focus on collecting and interpreting geological data to produce accurate block models and quality control reports essential for guiding excavation activities. Both roles demand meticulous documentation practices, with surveyors emphasizing spatial accuracy and legal compliance, while grade control technicians prioritize geological data integrity and operational reporting for production optimization.

Career Pathways and Professional Development

Surveyors in mining focus on land measurement, mapping, and resource estimation, leading to career paths in geospatial analysis, project management, and engineering roles. Grade Control Technicians specialize in analyzing ore quality and optimizing extraction processes, progressing toward roles in mine planning, production supervision, and quality assurance. Both career pathways require continuous professional development through certifications, software proficiency, and technical training to advance in the evolving mining industry.

Impact on Mining Efficiency and Productivity

Surveyors ensure precise mine mapping and boundary delineation, which directly supports efficient resource extraction and reduces operational errors. Grade Control Technicians continuously monitor ore grades at the face, optimizing blasting and excavation to enhance recovery rates and minimize dilution. Together, their roles synergistically improve mining productivity by maintaining accurate spatial data and controlling ore quality throughout production.

Surveyor vs Grade Control Technician Infographic

jobdiv.com

jobdiv.com