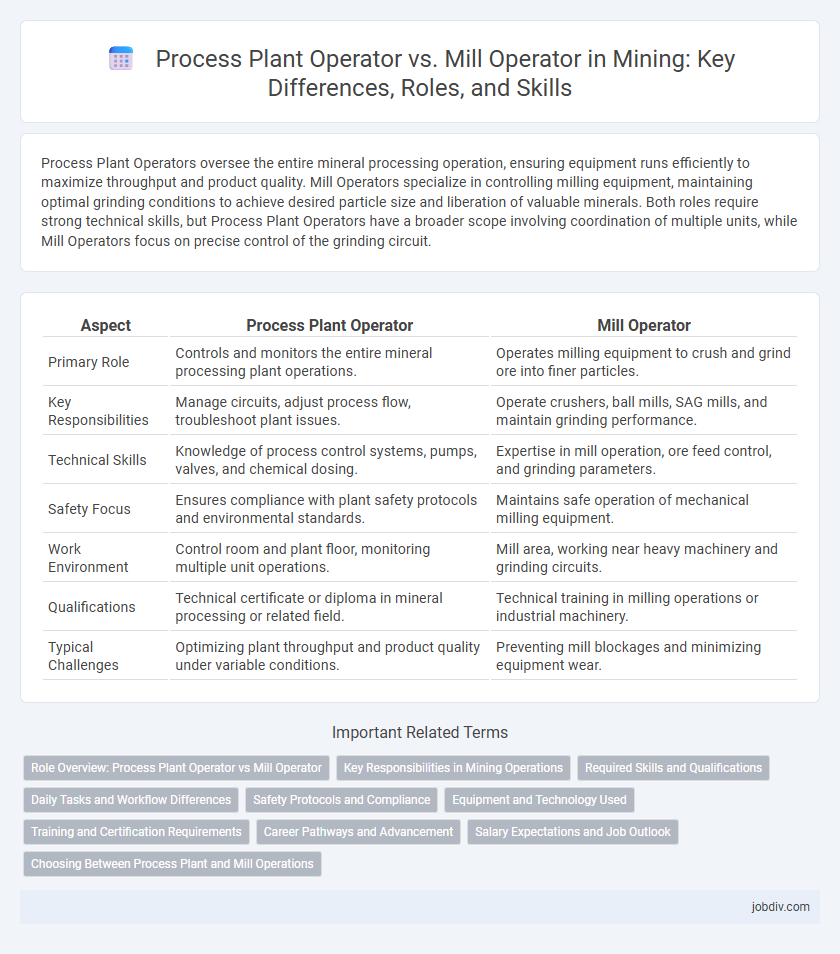

Process Plant Operators oversee the entire mineral processing operation, ensuring equipment runs efficiently to maximize throughput and product quality. Mill Operators specialize in controlling milling equipment, maintaining optimal grinding conditions to achieve desired particle size and liberation of valuable minerals. Both roles require strong technical skills, but Process Plant Operators have a broader scope involving coordination of multiple units, while Mill Operators focus on precise control of the grinding circuit.

Table of Comparison

| Aspect | Process Plant Operator | Mill Operator |

|---|---|---|

| Primary Role | Controls and monitors the entire mineral processing plant operations. | Operates milling equipment to crush and grind ore into finer particles. |

| Key Responsibilities | Manage circuits, adjust process flow, troubleshoot plant issues. | Operate crushers, ball mills, SAG mills, and maintain grinding performance. |

| Technical Skills | Knowledge of process control systems, pumps, valves, and chemical dosing. | Expertise in mill operation, ore feed control, and grinding parameters. |

| Safety Focus | Ensures compliance with plant safety protocols and environmental standards. | Maintains safe operation of mechanical milling equipment. |

| Work Environment | Control room and plant floor, monitoring multiple unit operations. | Mill area, working near heavy machinery and grinding circuits. |

| Qualifications | Technical certificate or diploma in mineral processing or related field. | Technical training in milling operations or industrial machinery. |

| Typical Challenges | Optimizing plant throughput and product quality under variable conditions. | Preventing mill blockages and minimizing equipment wear. |

Role Overview: Process Plant Operator vs Mill Operator

Process Plant Operators manage the entire processing facility, overseeing equipment operation, monitoring process parameters, and ensuring optimal material flow and safety compliance. Mill Operators specialize in operating and maintaining milling machines, focusing on crushing, grinding, and size reduction of ore to achieve desired particle sizes for further processing. Both roles require technical knowledge and adherence to safety standards but differ in scope, with Process Plant Operators handling broader processes and Mill Operators concentrating specifically on milling operations.

Key Responsibilities in Mining Operations

Process Plant Operators in mining oversee the entire processing flow, ensuring raw materials are efficiently transformed into valuable minerals through equipment monitoring, chemical balancing, and adherence to safety protocols. Mill Operators concentrate on managing grinding mills, controlling feed rates, and maintaining equipment to optimize ore crushing and size reduction. Both roles are critical for maximizing mineral recovery and maintaining smooth, continuous production in mining operations.

Required Skills and Qualifications

Process Plant Operators must have strong knowledge of process control systems, mechanical aptitude, and proficiency in monitoring equipment performance to ensure efficient plant operations. Mill Operators require skills in operating grinding and crushing machinery, understanding ore characteristics, and maintaining precise control over particle size to optimize mineral recovery. Both roles demand qualifications in mining engineering or related fields, safety certifications, and hands-on experience with heavy machinery and industrial processes.

Daily Tasks and Workflow Differences

Process Plant Operators oversee the entire mineral processing facility, ensuring all equipment runs efficiently to achieve optimal ore extraction from raw materials, while Mill Operators focus specifically on operating and maintaining grinding mills that reduce ore size for further processing. Daily tasks for Process Plant Operators include monitoring control systems, adjusting chemical feed rates, and coordinating with maintenance teams to prevent downtime, whereas Mill Operators primarily manage mill speed, liner replacements, and perform routine inspections to maintain grinding efficiency. Workflow differences highlight Process Plant Operators' broader scope in managing interconnected plant units, contrasting with Mill Operators' specialized focus on grinding operations within the milling circuit.

Safety Protocols and Compliance

Process Plant Operators and Mill Operators both adhere strictly to safety protocols and regulatory compliance to prevent accidents and ensure operational efficiency in mining environments. Process Plant Operators manage the entire processing system, requiring comprehensive knowledge of hazard identification and emergency response across multiple plant stages. Mill Operators focus on the grinding and milling stages, emphasizing machine-specific safety standards, equipment inspections, and lockout-tagout procedures to mitigate risks associated with heavy machinery.

Equipment and Technology Used

Process plant operators manage a range of advanced equipment including crushers, conveyors, flotation cells, and thickening systems to optimize mineral processing efficiency. Mill operators focus primarily on operating grinding mills like SAG, ball, and rod mills, utilizing control systems and automation technology to maintain precise particle size reduction. Both roles require expertise in monitoring instrumentation, troubleshooting mechanical issues, and ensuring equipment runs at optimal throughput for consistent ore processing.

Training and Certification Requirements

Process Plant Operators require specialized training in chemical processing, safety protocols, and equipment operation, often needing certifications like the National Institute for Occupational Safety and Health (NIOSH) or state-specific industrial licenses. Mill Operators focus on the operation and maintenance of milling machinery, typically requiring certification in mechanical systems and possibly a Mill Operator Certificate from recognized mining training institutions. Both roles demand adherence to occupational health and safety standards, but Process Plant Operators tend to have more extensive chemical process training while Mill Operators emphasize mechanical and equipment proficiency.

Career Pathways and Advancement

Process Plant Operators manage the overall operations of mineral processing plants, overseeing equipment to ensure efficient recovery and adherence to safety standards. Mill Operators specialize in controlling and monitoring grinding mills and related machinery, focusing on optimizing ore reduction processes. Career advancement for Process Plant Operators often leads to supervisory roles or plant management, while Mill Operators may progress to senior technical positions or specialized maintenance roles within the milling department.

Salary Expectations and Job Outlook

Process Plant Operators in mining sectors typically earn an average salary ranging from $55,000 to $80,000 annually, while Mill Operators' salaries range between $50,000 and $75,000, reflecting slightly lower compensation due to differing operational responsibilities. Job outlook for both roles remains steady, driven by ongoing demand for mineral processing and ore refinement, with Process Plant Operators experiencing marginally higher growth prospects due to their broader skill requirements. Employment opportunities continue to arise in mining regions with active extraction projects, emphasizing the importance of technical expertise and experience in process control and equipment maintenance.

Choosing Between Process Plant and Mill Operations

Choosing between a Process Plant Operator and a Mill Operator hinges on understanding the specific responsibilities and technical demands of each role in mining operations. Process Plant Operators manage the entire processing facility, overseeing equipment that extracts minerals from ore through crushing, grinding, and chemical treatments, while Mill Operators primarily focus on operating and maintaining grinding mills to reduce ore size. Evaluating expertise in equipment handling, safety protocols, and production efficiency is crucial for selecting the optimal career path within mining process operations.

Process Plant Operator vs Mill Operator Infographic

jobdiv.com

jobdiv.com