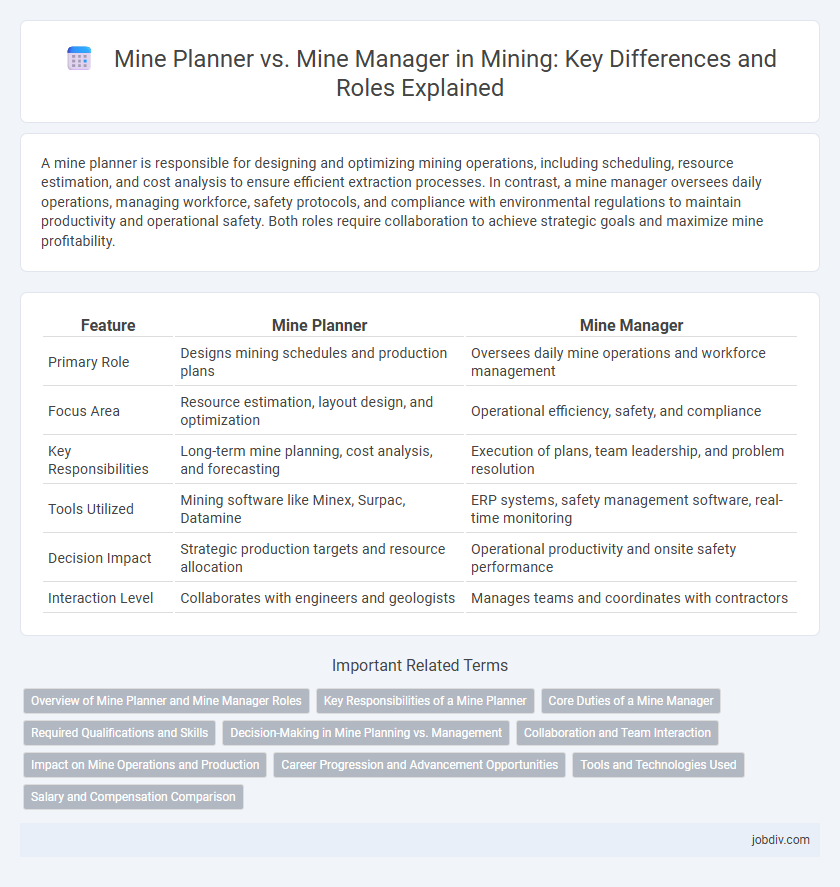

A mine planner is responsible for designing and optimizing mining operations, including scheduling, resource estimation, and cost analysis to ensure efficient extraction processes. In contrast, a mine manager oversees daily operations, managing workforce, safety protocols, and compliance with environmental regulations to maintain productivity and operational safety. Both roles require collaboration to achieve strategic goals and maximize mine profitability.

Table of Comparison

| Feature | Mine Planner | Mine Manager |

|---|---|---|

| Primary Role | Designs mining schedules and production plans | Oversees daily mine operations and workforce management |

| Focus Area | Resource estimation, layout design, and optimization | Operational efficiency, safety, and compliance |

| Key Responsibilities | Long-term mine planning, cost analysis, and forecasting | Execution of plans, team leadership, and problem resolution |

| Tools Utilized | Mining software like Minex, Surpac, Datamine | ERP systems, safety management software, real-time monitoring |

| Decision Impact | Strategic production targets and resource allocation | Operational productivity and onsite safety performance |

| Interaction Level | Collaborates with engineers and geologists | Manages teams and coordinates with contractors |

Overview of Mine Planner and Mine Manager Roles

Mine Planners develop detailed mining plans using geological data and production targets to optimize resource extraction, focusing on scheduling, cost control, and safety compliance. Mine Managers oversee overall mining operations, ensuring productivity, workforce management, regulatory adherence, and site safety. Both roles are critical for efficient mine development, but the planner emphasizes strategic layout and process optimization while the manager handles daily operational execution.

Key Responsibilities of a Mine Planner

Mine Planners are responsible for designing detailed mine operation schedules, optimizing resource extraction, and creating efficient production plans that align with long-term mining objectives. They analyze geological data, forecast material outputs, and develop cost-effective strategies to maximize mine productivity. Their role requires coordination with engineers and geologists to ensure safety compliance and adherence to environmental regulations throughout the mining process.

Core Duties of a Mine Manager

A Mine Manager oversees the entire mining operation, ensuring safety compliance, production targets, and budget management are met efficiently. Their core duties include coordinating labor and equipment, optimizing resource extraction, and implementing regulatory standards to maintain operational integrity. Unlike a Mine Planner who focuses on designing mine layouts and schedules, the Mine Manager takes a hands-on role in daily site management and strategic decision-making.

Required Qualifications and Skills

Mine Planners require strong technical skills in geology, mine design software, and resource estimation, with qualifications typically including a degree in mining engineering or geology. Mine Managers need leadership abilities, operational management expertise, and a comprehensive understanding of safety regulations, often holding advanced qualifications in mining engineering or business management. Both roles demand proficiency in project management and excellent communication skills to ensure efficient mine operations.

Decision-Making in Mine Planning vs. Management

Mine Planners focus on data-driven decision-making, utilizing geological models, scheduling software, and production forecasts to design efficient extraction strategies that maximize ore recovery and operational safety. Mine Managers prioritize operational decision-making, integrating real-time information on workforce, equipment, and site conditions to optimize daily production, cost control, and compliance with safety and environmental regulations. Both roles require critical decisions but differ in scope, with Planners emphasizing long-term optimization and Managers ensuring effective execution and adaptive control of mining operations.

Collaboration and Team Interaction

Mine planners and mine managers collaborate closely to ensure efficient mining operations by aligning strategic planning with day-to-day management. Effective communication between the two roles enhances resource allocation, safety protocols, and production schedules, fostering a cohesive team environment. Their interaction integrates technical planning with operational execution, driving productivity and minimizing operational risks.

Impact on Mine Operations and Production

The Mine Planner impacts mine operations by developing strategic plans that optimize resource extraction and ensure efficient use of equipment, directly influencing production schedules and cost management. The Mine Manager oversees day-to-day mine operations, ensuring plans are executed effectively while maintaining safety standards and regulatory compliance, which drives operational continuity and productivity. Together, their roles harmonize to maximize output, minimize downtime, and enhance overall mine performance.

Career Progression and Advancement Opportunities

Mine planners develop detailed operational strategies and schedules, focusing on resource estimation and efficient extraction methods using advanced software tools. Mine managers oversee daily mining operations, safety protocols, and workforce coordination, requiring strong leadership and decision-making skills. Career progression often starts with mine planning roles to gain technical expertise, advancing to mine management positions that emphasize operational oversight and strategic leadership.

Tools and Technologies Used

Mine planners primarily utilize advanced software such as Surpac, Datamine, and Micromine for geological modeling, pit optimization, and scheduling, enabling precise resource estimation and extraction sequencing. Mine managers rely on integrated management systems like SAP, Fleet Management Systems (FMS), and real-time monitoring tools to oversee operations, safety protocols, and equipment maintenance. Both roles leverage Geographic Information Systems (GIS) and drone technology for spatial analysis and operational efficiency in modern mining environments.

Salary and Compensation Comparison

Mine planners typically earn an average salary ranging from $70,000 to $100,000 annually, influenced by experience and location, whereas mine managers command higher compensation, often between $90,000 and $150,000 per year due to their broader responsibilities. Benefits for mine managers frequently include performance bonuses, profit sharing, and executive incentives, which contribute significantly to total remuneration packages. Salary disparities reflect differences in job scope, with mine managers overseeing operations and safety compliance, while mine planners focus on designing efficient extraction processes.

Mine Planner vs Mine Manager Infographic

jobdiv.com

jobdiv.com