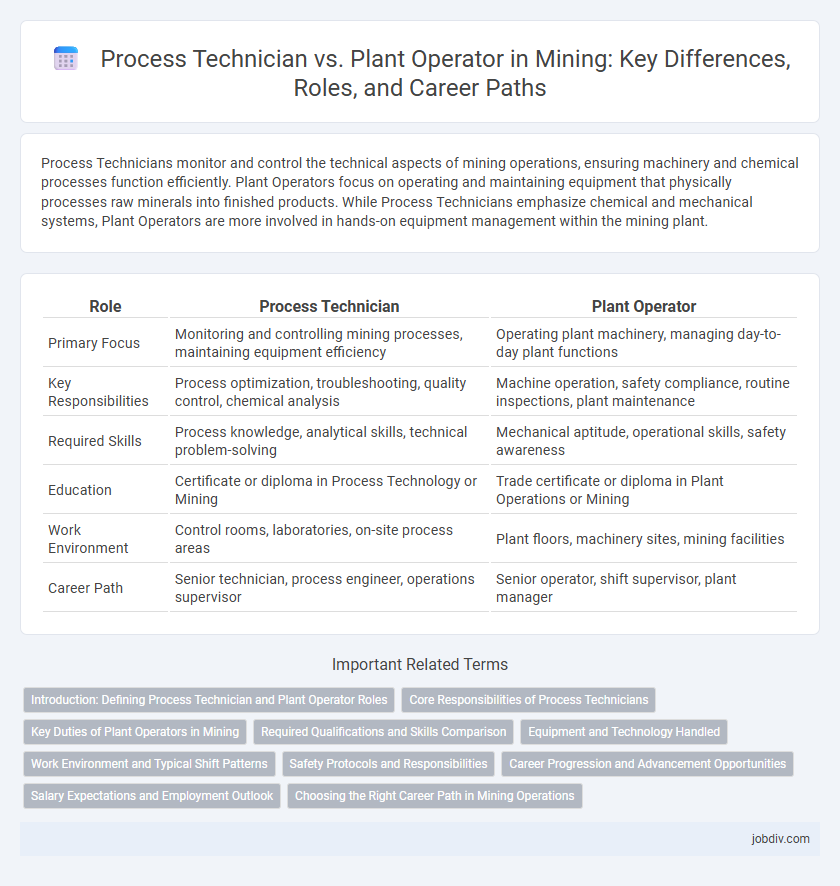

Process Technicians monitor and control the technical aspects of mining operations, ensuring machinery and chemical processes function efficiently. Plant Operators focus on operating and maintaining equipment that physically processes raw minerals into finished products. While Process Technicians emphasize chemical and mechanical systems, Plant Operators are more involved in hands-on equipment management within the mining plant.

Table of Comparison

| Role | Process Technician | Plant Operator |

|---|---|---|

| Primary Focus | Monitoring and controlling mining processes, maintaining equipment efficiency | Operating plant machinery, managing day-to-day plant functions |

| Key Responsibilities | Process optimization, troubleshooting, quality control, chemical analysis | Machine operation, safety compliance, routine inspections, plant maintenance |

| Required Skills | Process knowledge, analytical skills, technical problem-solving | Mechanical aptitude, operational skills, safety awareness |

| Education | Certificate or diploma in Process Technology or Mining | Trade certificate or diploma in Plant Operations or Mining |

| Work Environment | Control rooms, laboratories, on-site process areas | Plant floors, machinery sites, mining facilities |

| Career Path | Senior technician, process engineer, operations supervisor | Senior operator, shift supervisor, plant manager |

Introduction: Defining Process Technician and Plant Operator Roles

Process Technicians specialize in monitoring and controlling industrial processes to ensure efficient production and product quality in mining operations. Plant Operators manage the overall functioning of processing plants, overseeing equipment operation and maintenance to maximize output and safety. Both roles are critical for optimizing resource extraction and processing in the mining industry.

Core Responsibilities of Process Technicians

Process Technicians in mining primarily manage and control complex chemical and physical processes to optimize ore extraction and refinement. They monitor equipment performance, adjust process parameters, and ensure compliance with safety and quality standards to maximize production efficiency. Unlike Plant Operators who focus on mechanical operation and maintenance, Process Technicians emphasize process optimization and troubleshooting to improve mineral recovery rates and reduce operational costs.

Key Duties of Plant Operators in Mining

Plant operators in mining oversee the operation and maintenance of heavy machinery, ensuring optimal performance in mineral extraction and processing. They monitor equipment conditions, adjust controls to maintain production targets, and conduct safety checks to comply with mining regulations. Their role is vital in minimizing downtime and maximizing efficiency within the plant's operational workflow.

Required Qualifications and Skills Comparison

Process Technicians require technical diplomas in chemical or process engineering with expertise in monitoring and optimizing industrial systems, strong analytical skills, and proficiency in process control software. Plant Operators typically need certifications in equipment operation, hands-on experience with machinery, and knowledge of safety protocols, emphasizing mechanical aptitude and real-time problem-solving abilities. Both roles demand attention to detail and adherence to safety standards, but Process Technicians focus more on process optimization, while Plant Operators concentrate on equipment management and operation.

Equipment and Technology Handled

Process Technicians manage and optimize chemical processes using advanced control systems and laboratory equipment to ensure product quality and safety. Plant Operators oversee a wide range of heavy machinery, including crushers, conveyors, and pumps, ensuring optimal performance and maintenance to support continuous mining operations. Both roles require proficiency with automation technologies, but Process Technicians focus more on process control software, while Plant Operators emphasize mechanical equipment operation.

Work Environment and Typical Shift Patterns

Process Technicians in mining typically work in controlled environments within processing plants, handling chemical and mechanical systems, whereas Plant Operators often operate heavy machinery outdoors or in less controlled industrial settings. Shift patterns for Process Technicians commonly involve rotating or fixed shifts, often lasting 8 to 12 hours, matching plant operational demands. Plant Operators frequently work similar shift durations but may face more variable schedules due to equipment maintenance and site conditions.

Safety Protocols and Responsibilities

Process Technicians and Plant Operators both play critical roles in mining safety protocols, with Process Technicians focusing on monitoring chemical reactions and adjusting process parameters to prevent hazards. Plant Operators are responsible for overseeing machinery operation, ensuring equipment functionality, and responding swiftly to mechanical failures to avoid accidents. Both roles require strict adherence to safety regulations, hazard identification, and emergency response procedures to maintain a secure mining environment.

Career Progression and Advancement Opportunities

Process Technicians in mining typically advance by gaining specialized skills in chemical processing and system troubleshooting, leading to supervisory roles or technical expert positions. Plant Operators generally progress through mastering equipment operation and maintenance, moving towards shift management or operational coordinator roles. Both career paths offer opportunities for advancement into management or engineering positions, with growth influenced by certifications, experience, and the complexity of the plant.

Salary Expectations and Employment Outlook

Process Technicians in mining typically earn between $55,000 and $75,000 annually, while Plant Operators' salaries range from $45,000 to $65,000, reflecting differences in technical responsibilities and experience levels. Employment outlook for both roles remains strong due to ongoing demand for skilled workers in mineral processing facilities and mining plants, with Process Technicians experiencing slightly higher growth rates driven by advanced automation and process optimization needs. Job stability and opportunities for advancement are favorable in mining regions where extensive mineral extraction projects support sustained operations and workforce expansion.

Choosing the Right Career Path in Mining Operations

Process Technicians specialize in monitoring and optimizing chemical processes, ensuring efficient mineral extraction and product quality, while Plant Operators manage the overall functioning of mining plants, including equipment operation and maintenance. Choosing between these roles depends on your preference for detailed process control and troubleshooting versus overseeing plant systems and operational logistics in mining operations. Skills in process control technology, safety protocols, and equipment management are critical for both career paths within the mining industry.

Process Technician vs Plant Operator Infographic

jobdiv.com

jobdiv.com