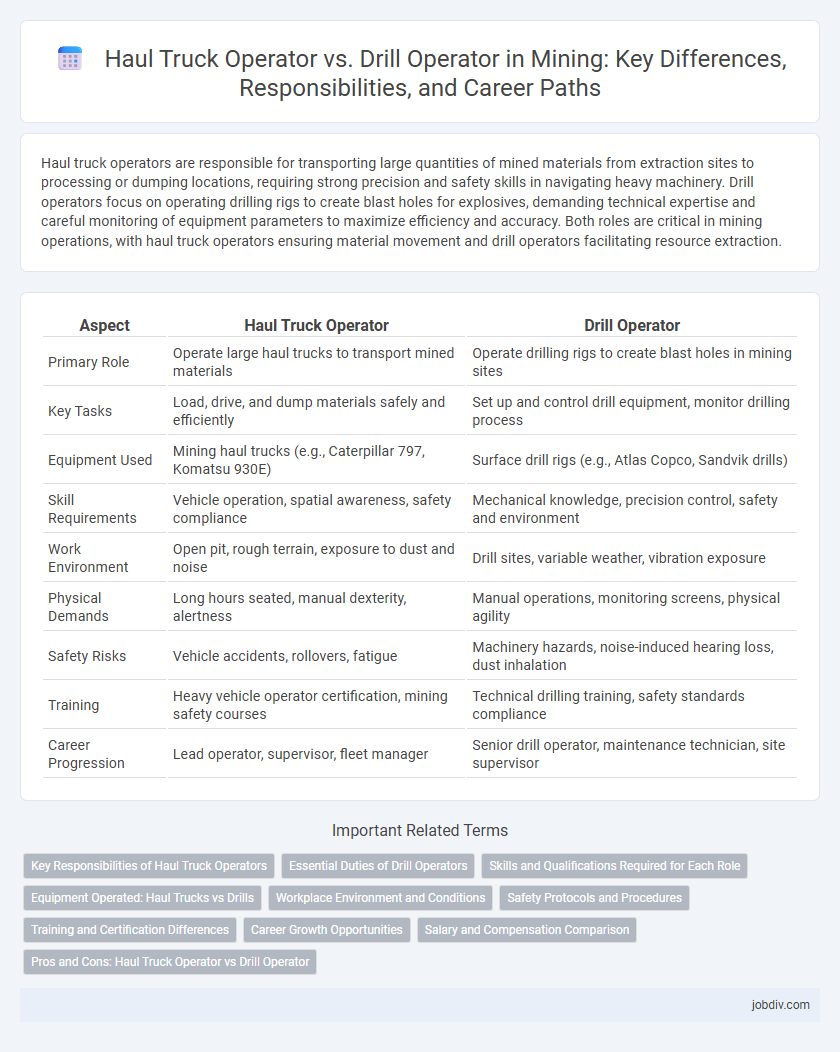

Haul truck operators are responsible for transporting large quantities of mined materials from extraction sites to processing or dumping locations, requiring strong precision and safety skills in navigating heavy machinery. Drill operators focus on operating drilling rigs to create blast holes for explosives, demanding technical expertise and careful monitoring of equipment parameters to maximize efficiency and accuracy. Both roles are critical in mining operations, with haul truck operators ensuring material movement and drill operators facilitating resource extraction.

Table of Comparison

| Aspect | Haul Truck Operator | Drill Operator |

|---|---|---|

| Primary Role | Operate large haul trucks to transport mined materials | Operate drilling rigs to create blast holes in mining sites |

| Key Tasks | Load, drive, and dump materials safely and efficiently | Set up and control drill equipment, monitor drilling process |

| Equipment Used | Mining haul trucks (e.g., Caterpillar 797, Komatsu 930E) | Surface drill rigs (e.g., Atlas Copco, Sandvik drills) |

| Skill Requirements | Vehicle operation, spatial awareness, safety compliance | Mechanical knowledge, precision control, safety and environment |

| Work Environment | Open pit, rough terrain, exposure to dust and noise | Drill sites, variable weather, vibration exposure |

| Physical Demands | Long hours seated, manual dexterity, alertness | Manual operations, monitoring screens, physical agility |

| Safety Risks | Vehicle accidents, rollovers, fatigue | Machinery hazards, noise-induced hearing loss, dust inhalation |

| Training | Heavy vehicle operator certification, mining safety courses | Technical drilling training, safety standards compliance |

| Career Progression | Lead operator, supervisor, fleet manager | Senior drill operator, maintenance technician, site supervisor |

Key Responsibilities of Haul Truck Operators

Haul truck operators are responsible for safely transporting large volumes of ore and waste material between mining sites and processing facilities, ensuring efficient cycle times and minimizing equipment downtime. They conduct pre-trip inspections, monitor truck performance, and maintain communication with dispatch to optimize haul routes and avoid delays. Precision in load management and adherence to safety protocols are critical to prevent accidents and maintain operational flow in open-pit and underground mining environments.

Essential Duties of Drill Operators

Drill operators specialize in operating and maintaining drilling rigs to create blast holes for extraction, ensuring precision in depth and angle to optimize blasting efficiency. Their essential duties include monitoring equipment performance, conducting routine inspections, and adhering to safety protocols to prevent accidents during drilling operations. Unlike haul truck operators who focus on transporting materials, drill operators directly influence blast pattern quality and overall mine productivity through accurate hole placement.

Skills and Qualifications Required for Each Role

Haul truck operators require strong vehicle control skills, knowledge of heavy machinery maintenance, and the ability to navigate challenging terrains safely, often with a heavy equipment operator certification. Drill operators need expertise in operating drilling rigs, understanding geological data, and adhering to safety protocols, typically requiring specialized training in drilling techniques and certification in mine safety. Both roles demand physical stamina, attention to detail, and compliance with mining regulations, but drill operators must have more technical knowledge related to drilling operations, while haul truck operators focus on transportation efficiency.

Equipment Operated: Haul Trucks vs Drills

Haul Truck Operators skillfully manage large-capacity haul trucks designed for transporting massive loads of ore and overburden across mining sites, optimizing material movement efficiency. Drill Operators handle advanced drilling rigs essential for creating blast holes and exploration boreholes, ensuring precise penetration and rock fragmentation. Understanding the distinct equipment specifications like truck payload capacity versus drill bit diameter is crucial for matching operator skills to mining operations.

Workplace Environment and Conditions

Haul truck operators work in dynamic, often dusty open-pit mine environments, managing large vehicles over rough terrain and varying weather conditions, which demands high physical endurance and awareness of safety protocols. Drill operators operate heavy drilling machinery in confined and noisy settings, frequently exposed to vibrations and airborne particles, requiring precise control to maintain drill accuracy and avoid equipment damage. Both roles involve shift work with potential exposure to extreme temperatures, but haul truck operators experience more mobility-related challenges, while drill operators face constant mechanical interaction in a stationary position.

Safety Protocols and Procedures

Haul truck operators and drill operators follow stringent safety protocols tailored to their roles in mining operations, ensuring compliance with industry standards like MSHA and OSHA. Haul truck operators must adhere to procedures regarding vehicle inspections, load securement, and blind spot awareness to prevent collisions and maintain site safety. Drill operators focus on maintaining equipment stability, performing pre-shift safety checks, and following blast area restrictions to minimize hazards associated with drilling operations.

Training and Certification Differences

Haul truck operators typically require training in heavy machinery operation, safety protocols, and site navigation, with certifications such as the National Mining Association's haul truck operator license. Drill operators undergo specialized training focused on drill mechanics, precision techniques, and explosive handling, often obtaining certifications like the Mine Safety and Health Administration (MSHA) Part 46 Rigging and Hoisting. The key distinction lies in the drill operator's emphasis on technical expertise for controlled drilling processes versus the haul truck operator's focus on vehicle maneuvering and load management.

Career Growth Opportunities

Haul truck operators in mining often experience faster career growth through opportunities in equipment supervision and fleet management, given their direct involvement in material transport logistics. Drill operators, while specialized in drilling techniques and geological assessment, have pathways into technical roles such as drilling engineering or mine planning that require advanced skill sets. Both positions offer distinct career trajectories, with haul truck operators leaning toward operational leadership and drill operators toward technical expertise and engineering roles.

Salary and Compensation Comparison

Haul Truck Operators in mining typically earn an average annual salary ranging from $55,000 to $80,000, with compensation influenced by factors such as experience, location, and shift differentials. Drill Operators often see slightly higher pay scales, averaging between $60,000 and $85,000 annually, due to the technical expertise required for precision drilling tasks. Both roles may receive additional benefits including overtime pay, bonuses, and allowances for hazardous work environments, impacting total compensation packages significantly.

Pros and Cons: Haul Truck Operator vs Drill Operator

Haul Truck Operators benefit from high visibility and relatively straightforward controls, allowing efficient transportation of mined materials but face physically demanding conditions and long hours of repetitive motion. Drill Operators gain expertise in precision and technical skills with the advantage of dynamic, skill-intensive tasks, though they often endure noisy environments and require continuous focus to maintain accuracy and safety. Both roles are critical in mining operations, with haul truck operators emphasizing endurance and logistics, while drill operators prioritize technical proficiency and operational precision.

Haul Truck Operator vs Drill Operator Infographic

jobdiv.com

jobdiv.com