Mine Planners develop strategic layouts and timelines for efficient resource extraction, optimizing long-term operational goals through geological data analysis. Production Schedulers focus on short-term execution, coordinating daily activities and equipment to meet production targets and minimize delays. Both roles are essential for synchronizing mine operations, but Mine Planners address future planning while Production Schedulers manage immediate workflow.

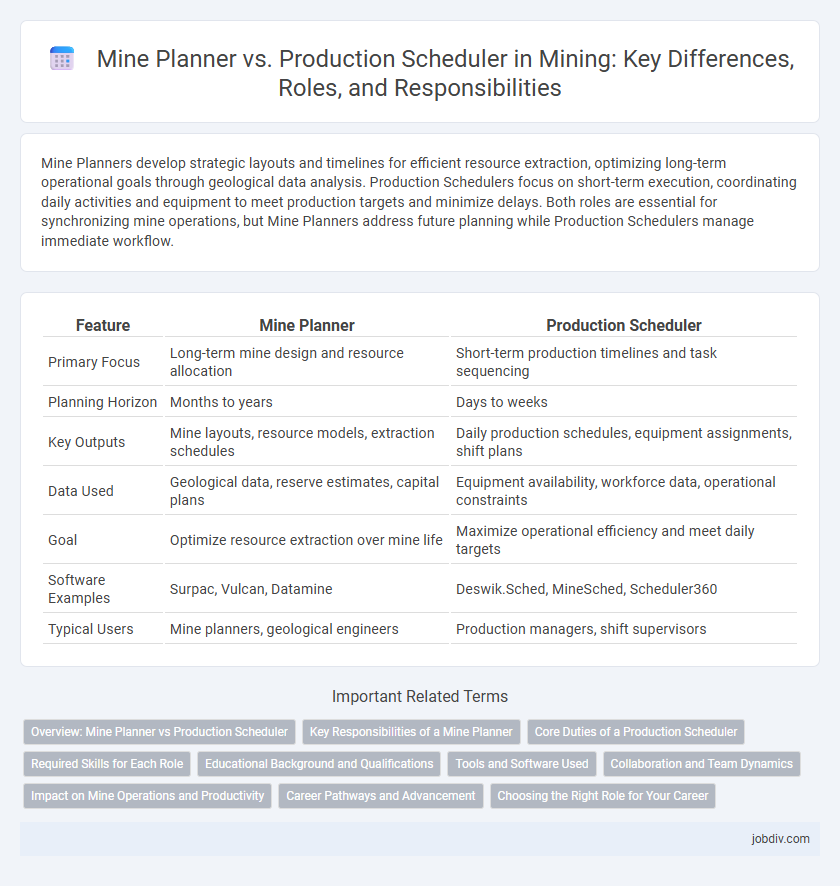

Table of Comparison

| Feature | Mine Planner | Production Scheduler |

|---|---|---|

| Primary Focus | Long-term mine design and resource allocation | Short-term production timelines and task sequencing |

| Planning Horizon | Months to years | Days to weeks |

| Key Outputs | Mine layouts, resource models, extraction schedules | Daily production schedules, equipment assignments, shift plans |

| Data Used | Geological data, reserve estimates, capital plans | Equipment availability, workforce data, operational constraints |

| Goal | Optimize resource extraction over mine life | Maximize operational efficiency and meet daily targets |

| Software Examples | Surpac, Vulcan, Datamine | Deswik.Sched, MineSched, Scheduler360 |

| Typical Users | Mine planners, geological engineers | Production managers, shift supervisors |

Overview: Mine Planner vs Production Scheduler

Mine Planner focuses on designing efficient mine layouts and long-term extraction strategies to optimize resource recovery and minimize operational costs. Production Scheduler concentrates on short-term task allocation and sequencing, ensuring daily operations align with production targets and equipment availability. Both roles are critical for maximizing mine productivity but operate on different planning horizons and detail levels.

Key Responsibilities of a Mine Planner

A Mine Planner develops detailed plans for efficient extraction of minerals, emphasizing scheduling, resource allocation, and safety compliance. Responsibilities include designing mine layouts, optimizing production sequences, and forecasting material outputs using geological data and software tools. They ensure alignment with environmental regulations and collaborate with engineers to maximize operational productivity and cost-effectiveness.

Core Duties of a Production Scheduler

A Production Scheduler in mining is responsible for creating detailed schedules that coordinate mining activities with processing plant capacity to maximize efficiency and output. They analyze production targets, allocate resources, and adjust schedules based on operational data and equipment availability to minimize downtime and meet deadlines. Their core duties include optimizing workflow sequences, monitoring progress against plans, and ensuring alignment between extraction rates and processing requirements.

Required Skills for Each Role

Mine Planners require strong expertise in geological modeling, resource estimation, and long-term strategic planning to develop efficient mine designs and schedules. Production Schedulers focus on operational management skills, including short-term scheduling, workforce coordination, and equipment allocation to optimize daily production. Both roles demand proficiency in mining software such as Surpac or Vulcan, but Mine Planners emphasize analytical and forecasting abilities, while Production Schedulers prioritize real-time problem-solving and communication skills.

Educational Background and Qualifications

Mine planners typically hold degrees in mining engineering or geological engineering, emphasizing strong skills in geological data analysis, mine design, and long-term strategic planning. Production schedulers often have backgrounds in mining engineering, industrial engineering, or related fields, focusing on operations management, resource allocation, and short-term production optimization. Certifications such as Professional Engineer (PE) or scheduling-specific credentials like PMI Scheduling Professional (PMI-SP) enhance qualifications for both roles.

Tools and Software Used

Mine planners primarily use geological modeling software like Surpac, Datamine, and Vulcan to design efficient extraction sequences and optimize resource utilization. Production schedulers rely heavily on scheduling tools such as Minemax, MineSched, and DESW scheduling modules to create detailed production timelines and align operational activities with supply chain demands. Integration between geological, planning, and scheduling software enhances decision-making accuracy and operational efficiency in mining projects.

Collaboration and Team Dynamics

Mine Planners and Production Schedulers collaborate closely to optimize resource allocation and production timelines, ensuring seamless operational flow in mining projects. Effective team dynamics between these roles involve continuous communication and data sharing to adjust plans based on real-time site conditions and equipment availability. This collaboration enhances decision-making accuracy, reduces bottlenecks, and maximizes overall mine productivity.

Impact on Mine Operations and Productivity

Mine planners strategically design extraction sequences and pit layouts, directly influencing resource recovery rates and long-term operational efficiency. Production schedulers allocate daily tasks and equipment, optimizing workforce deployment and machinery utilization to meet short-term production targets. Effective coordination between planning and scheduling maximizes ore yield, minimizes downtime, and enhances overall mine productivity.

Career Pathways and Advancement

Mine Planners develop strategic extraction plans using geological data and software, typically advancing to senior planning or project management roles through expertise in resource optimization. Production Schedulers coordinate daily mining operations to meet output targets, often progressing to operations management or logistics leadership by mastering workflow efficiency. Both roles require strong analytical skills and offer pathways to executive positions within the mining industry by driving operational excellence and cost-effective production.

Choosing the Right Role for Your Career

Mine planners focus on designing and optimizing mine layouts to maximize resource extraction and ensure safety, leveraging geological data and modeling software. Production schedulers coordinate day-to-day mining operations to meet production targets while managing equipment and workforce efficiently. Choosing between these roles depends on whether you prefer strategic design and long-term planning or dynamic operational management within the mining industry.

Mine Planner vs Production Scheduler Infographic

jobdiv.com

jobdiv.com