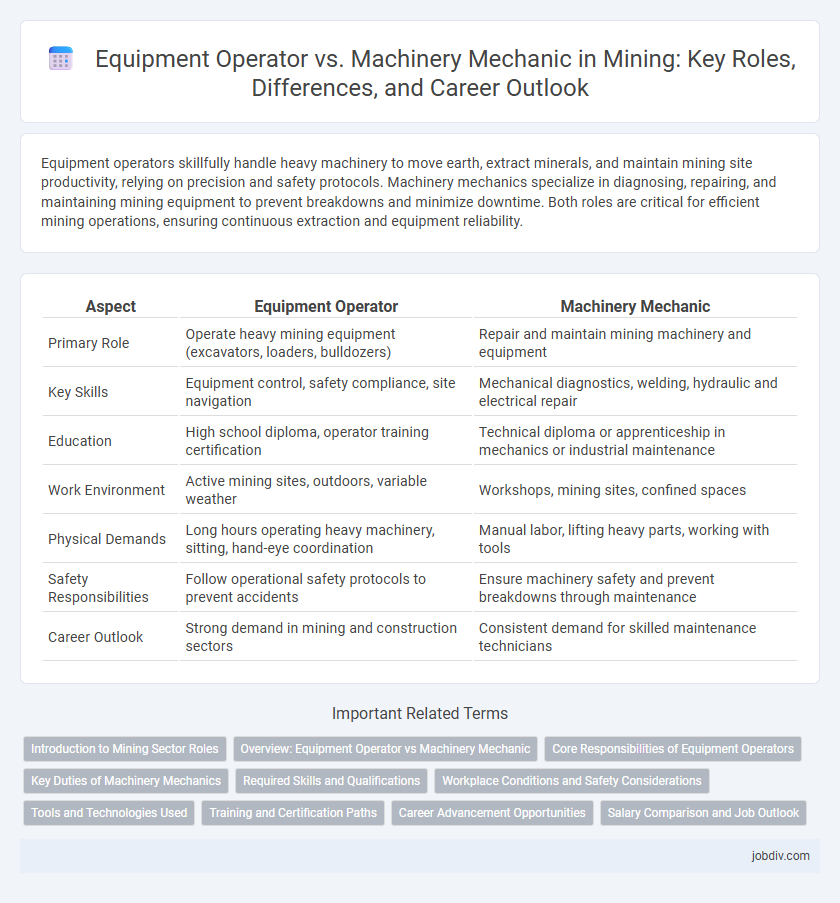

Equipment operators skillfully handle heavy machinery to move earth, extract minerals, and maintain mining site productivity, relying on precision and safety protocols. Machinery mechanics specialize in diagnosing, repairing, and maintaining mining equipment to prevent breakdowns and minimize downtime. Both roles are critical for efficient mining operations, ensuring continuous extraction and equipment reliability.

Table of Comparison

| Aspect | Equipment Operator | Machinery Mechanic |

|---|---|---|

| Primary Role | Operate heavy mining equipment (excavators, loaders, bulldozers) | Repair and maintain mining machinery and equipment |

| Key Skills | Equipment control, safety compliance, site navigation | Mechanical diagnostics, welding, hydraulic and electrical repair |

| Education | High school diploma, operator training certification | Technical diploma or apprenticeship in mechanics or industrial maintenance |

| Work Environment | Active mining sites, outdoors, variable weather | Workshops, mining sites, confined spaces |

| Physical Demands | Long hours operating heavy machinery, sitting, hand-eye coordination | Manual labor, lifting heavy parts, working with tools |

| Safety Responsibilities | Follow operational safety protocols to prevent accidents | Ensure machinery safety and prevent breakdowns through maintenance |

| Career Outlook | Strong demand in mining and construction sectors | Consistent demand for skilled maintenance technicians |

Introduction to Mining Sector Roles

Equipment operators in the mining sector control heavy machinery such as excavators, bulldozers, and haul trucks essential for ore extraction and site preparation. Machinery mechanics specialize in diagnosing, repairing, and maintaining mining equipment to ensure operational efficiency and minimize downtime. Both roles are critical for maintaining production flow and safety standards within mining operations.

Overview: Equipment Operator vs Machinery Mechanic

Equipment operators in mining control and maneuver heavy machinery such as excavators, loaders, and bulldozers to extract minerals efficiently. Machinery mechanics specialize in diagnosing, repairing, and maintaining mining equipment to ensure operational reliability and minimize downtime. Both roles are critical, with operators focusing on fieldwork and mechanics on technical support and machinery longevity.

Core Responsibilities of Equipment Operators

Equipment operators in mining are responsible for operating heavy machinery such as loaders, bulldozers, and haul trucks to extract and transport materials efficiently and safely. They monitor equipment performance, perform routine maintenance checks, and adhere to safety protocols to minimize downtime and prevent accidents. Proficiency in interpreting site plans and coordinating with other crew members ensures smooth operation within dynamic mining environments.

Key Duties of Machinery Mechanics

Machinery mechanics in mining are responsible for inspecting, diagnosing, and repairing heavy equipment to ensure optimal performance and safety. They perform preventative maintenance, troubleshoot mechanical issues, and replace worn or damaged parts to minimize equipment downtime. Their expertise is critical in maintaining the reliability of excavators, haul trucks, loaders, and conveyors used in mining operations.

Required Skills and Qualifications

Equipment operators in mining require proficiency in heavy machinery control, spatial awareness, and adherence to safety protocols, often necessitating certifications in equipment operation. Machinery mechanics must possess advanced diagnostic skills, mechanical aptitude for repair and maintenance, and expertise in hydraulic and electrical systems, typically supported by technical training or apprenticeship credentials. Both roles demand strong problem-solving abilities and a comprehensive understanding of mining equipment functionality.

Workplace Conditions and Safety Considerations

Equipment operators and machinery mechanics in mining face distinct workplace conditions tailored to their roles, where operators manage heavy machinery often exposed to variable weather and uneven terrain, requiring constant vigilance for operational safety. Machinery mechanics typically work in repair shops or maintenance bays, dealing with heavy tools and machinery parts, necessitating strict adherence to safety protocols to prevent injuries from mechanical failures or hazardous materials. Both roles demand rigorous use of personal protective equipment (PPE) and adherence to mining safety standards to mitigate risks associated with physical labor and equipment handling.

Tools and Technologies Used

Equipment operators in mining primarily rely on advanced machinery such as haul trucks, loaders, and excavators equipped with GPS and telematics systems for precision and efficiency. Machinery mechanics use diagnostic tools, hydraulic analyzers, and welding equipment to maintain and repair heavy mining equipment, ensuring optimal performance and safety. Both roles integrate digital technologies like computerized maintenance management systems (CMMS) to streamline operations and reduce downtime.

Training and Certification Paths

Equipment operators in mining typically undergo vocational training programs focused on heavy machinery operation, with certifications such as the National Center for Construction Education and Research (NCCER) operator credentials. Machinery mechanics require specialized technical education, often through apprenticeships or technical colleges, emphasizing repair and maintenance skills, and certifications like the Certified Maintenance & Reliability Technician (CMRT) credential. Both roles demand rigorous safety training aligned with Mine Safety and Health Administration (MSHA) standards to ensure operational efficiency and compliance.

Career Advancement Opportunities

Equipment operators in mining gain hands-on experience with heavy machinery, enabling progression to supervisory roles or specialized operating positions. Machinery mechanics possess in-depth technical skills for maintaining and repairing equipment, offering advancement into lead mechanic or maintenance management roles. Both career paths provide opportunities for certifications and cross-training, enhancing prospects for higher responsibility and increased earnings within mining operations.

Salary Comparison and Job Outlook

Equipment operators in mining earn an average annual salary of $45,000 to $65,000, with steady demand driven by ongoing extraction projects and infrastructure maintenance. Machinery mechanics, responsible for repairing and maintaining heavy mining equipment, typically earn higher wages ranging from $55,000 to $75,000 due to specialized technical skills and increased job complexity. Both roles show positive job outlooks, with machinery mechanics experiencing slightly faster employment growth of 5-7% over the next decade compared to 3-5% for equipment operators.

Equipment Operator vs Machinery Mechanic Infographic

jobdiv.com

jobdiv.com