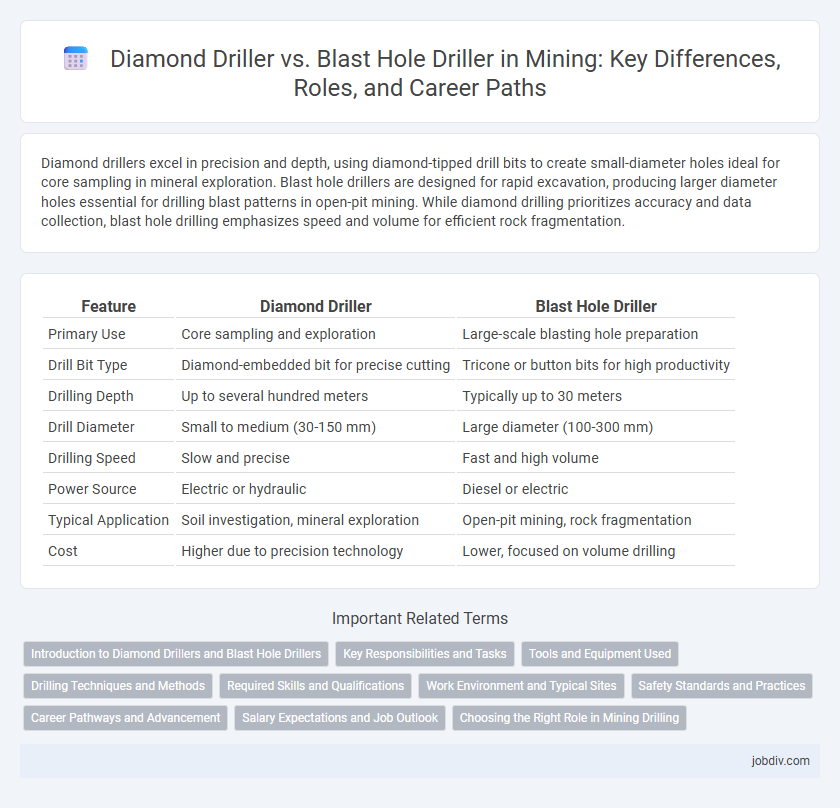

Diamond drillers excel in precision and depth, using diamond-tipped drill bits to create small-diameter holes ideal for core sampling in mineral exploration. Blast hole drillers are designed for rapid excavation, producing larger diameter holes essential for drilling blast patterns in open-pit mining. While diamond drilling prioritizes accuracy and data collection, blast hole drilling emphasizes speed and volume for efficient rock fragmentation.

Table of Comparison

| Feature | Diamond Driller | Blast Hole Driller |

|---|---|---|

| Primary Use | Core sampling and exploration | Large-scale blasting hole preparation |

| Drill Bit Type | Diamond-embedded bit for precise cutting | Tricone or button bits for high productivity |

| Drilling Depth | Up to several hundred meters | Typically up to 30 meters |

| Drill Diameter | Small to medium (30-150 mm) | Large diameter (100-300 mm) |

| Drilling Speed | Slow and precise | Fast and high volume |

| Power Source | Electric or hydraulic | Diesel or electric |

| Typical Application | Soil investigation, mineral exploration | Open-pit mining, rock fragmentation |

| Cost | Higher due to precision technology | Lower, focused on volume drilling |

Introduction to Diamond Drillers and Blast Hole Drillers

Diamond drillers use diamond-tipped drill bits to create precise, deep core samples in hard rock mining, enabling detailed geological analysis. Blast hole drillers employ large, heavy-duty rotary or percussion drills to drill multiple holes for explosive placement, facilitating controlled rock fragmentation in surface mining operations. Both drilling types are essential for efficient mineral extraction, with diamond drillers specializing in exploration and blast hole drillers optimizing blasting efficiency.

Key Responsibilities and Tasks

Diamond drillers specialize in extracting core samples using diamond-tipped drill bits to assess mineral composition and geological structures, ensuring precise data for exploration and resource estimation. Blast hole drillers operate large, heavy-duty equipment to create holes for explosives, facilitating the fragmentation of rock in surface mining operations and maintaining safety and efficiency standards. Both roles require expertise in equipment maintenance, adherence to safety protocols, and coordination with engineering teams to optimize drilling accuracy and productivity.

Tools and Equipment Used

Diamond drillers utilize diamond-tipped drill bits designed for precision cutting and sampling of hard rock formations, often mounted on rigs equipped with mud pumps and core barrels to extract solid rock cores. Blast hole drillers operate rotary drill rigs with tungsten carbide bits, engineered for rapid drilling of large-diameter holes used in explosives placement for fragmentation. The equipment for diamond drilling prioritizes accuracy and core recovery, whereas blast hole drilling emphasizes speed and hole diameter to optimize blasting efficiency.

Drilling Techniques and Methods

Diamond drilling utilizes a rotating drill bit embedded with industrial diamonds to cut through rock and obtain core samples, allowing precise geological analysis and minimal surrounding rock damage. Blast hole drilling employs larger, heavy-duty rotary or percussion drills designed to create deep, wide holes for explosives, optimizing fragmentation for efficient ore extraction. The diamond driller emphasizes accuracy and core recovery, while blast hole drilling focuses on rapid hole production and blast efficiency in mining operations.

Required Skills and Qualifications

Diamond drillers require advanced knowledge in geology, precision handling of diamond-tipped drill bits, and expertise in core sampling techniques, often supported by certifications in mining or geological engineering. Blast hole drillers must possess strong mechanical skills for operating large rotary drills, understanding of explosives safety protocols, and experience in site layout planning, typically gained through vocational training or apprenticeships in mining operations. Both roles demand physical stamina, attention to detail, and adherence to strict safety regulations to ensure efficient and secure drilling processes.

Work Environment and Typical Sites

Diamond drillers operate primarily in exploration sites such as hard rock quarries and underground mines where precision and core sample extraction are critical for assessing mineral deposits. Blast hole drillers work mainly in open-pit mines and large-scale mining operations where high-production drilling is required to create blast patterns for ore fragmentation. The work environment for diamond drilling is generally confined and involves detailed technical work, while blast hole drilling involves exposure to dust, noise, and harsh outdoor conditions.

Safety Standards and Practices

Diamond drillers utilize precision equipment designed to minimize rock fragmentation, reducing airborne dust and vibrations, thereby enhancing on-site safety. Blast hole drillers operate with larger rigs that require strict adherence to explosive handling protocols and blast zone exclusion to prevent accidents. Rigorous compliance with OSHA and MSHA safety standards is mandatory for both drilling methods to ensure worker protection and prevent hazardous incidents.

Career Pathways and Advancement

Diamond drillers specialize in precision drilling for core sampling and exploration, gaining expertise in geology and advanced drilling technologies that open pathways to roles in mine planning and geological analysis. Blast hole drillers focus on creating large-diameter holes for explosive placement, developing skills in operational coordination and equipment maintenance, leading to supervisory positions in blasting operations and mine production management. Both career pathways offer advancement opportunities through certifications, safety training, and experience in increasingly complex mining projects.

Salary Expectations and Job Outlook

Diamond drillers typically earn higher salaries than blast hole drillers due to the specialized skills required for precision drilling in exploration and core sampling, with average annual wages ranging from $60,000 to $85,000. Blast hole drillers focus on creating large-diameter holes for explosive placement in open-pit mining and generally have salaries between $50,000 and $70,000. Job outlook for diamond drillers shows steady growth driven by increased mineral exploration, while blast hole drillers experience stable demand tied to ongoing surface mining operations.

Choosing the Right Role in Mining Drilling

Diamond drillers specialize in extracting core samples with high precision using diamond-tipped drill bits, ideal for geological exploration and mineral analysis. Blast hole drillers operate heavier machinery to create large-diameter holes for explosives, facilitating efficient rock fragmentation in open-pit mining. Selecting the appropriate role depends on project requirements, with diamond drilling suited for detailed study and blast hole drilling essential for bulk excavation.

Diamond Driller vs Blast Hole Driller Infographic

jobdiv.com

jobdiv.com