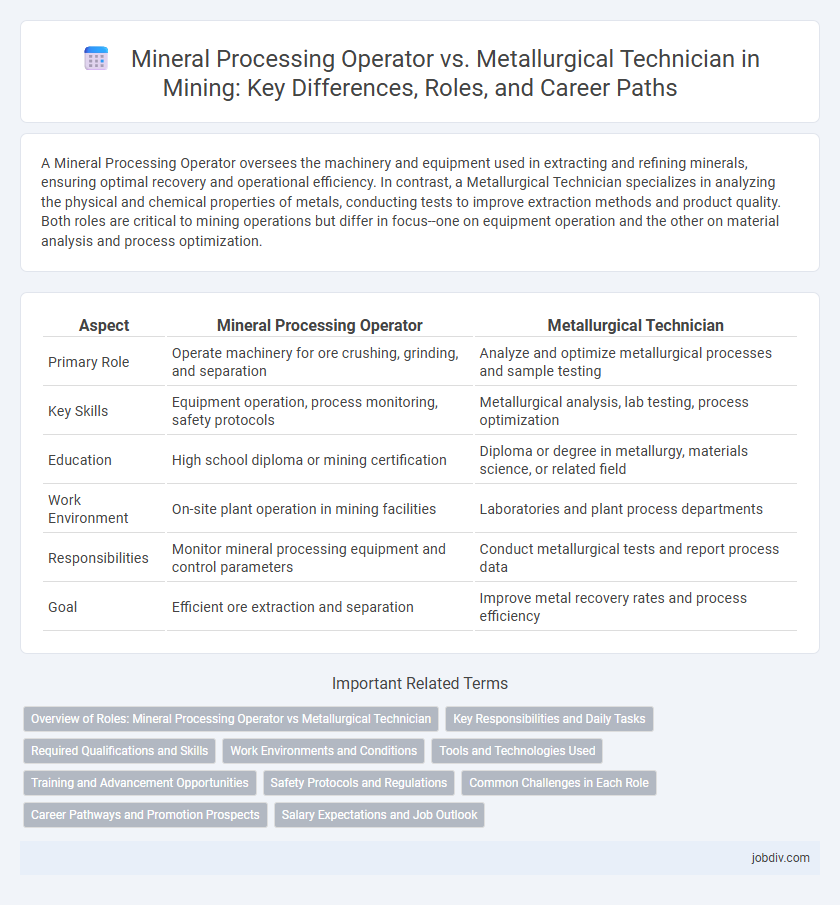

A Mineral Processing Operator oversees the machinery and equipment used in extracting and refining minerals, ensuring optimal recovery and operational efficiency. In contrast, a Metallurgical Technician specializes in analyzing the physical and chemical properties of metals, conducting tests to improve extraction methods and product quality. Both roles are critical to mining operations but differ in focus--one on equipment operation and the other on material analysis and process optimization.

Table of Comparison

| Aspect | Mineral Processing Operator | Metallurgical Technician |

|---|---|---|

| Primary Role | Operate machinery for ore crushing, grinding, and separation | Analyze and optimize metallurgical processes and sample testing |

| Key Skills | Equipment operation, process monitoring, safety protocols | Metallurgical analysis, lab testing, process optimization |

| Education | High school diploma or mining certification | Diploma or degree in metallurgy, materials science, or related field |

| Work Environment | On-site plant operation in mining facilities | Laboratories and plant process departments |

| Responsibilities | Monitor mineral processing equipment and control parameters | Conduct metallurgical tests and report process data |

| Goal | Efficient ore extraction and separation | Improve metal recovery rates and process efficiency |

Overview of Roles: Mineral Processing Operator vs Metallurgical Technician

Mineral Processing Operators manage equipment that separates valuable minerals from ore, ensuring efficient extraction and optimal plant performance in mining operations. Metallurgical Technicians analyze the physical and chemical properties of metals and minerals, conducting tests to improve extraction processes and product quality. While operators focus on hands-on management of processing machinery, technicians emphasize laboratory analysis and process optimization.

Key Responsibilities and Daily Tasks

Mineral Processing Operators oversee the operation and maintenance of equipment that crushes, grinds, and processes ore to extract valuable minerals, ensuring optimal recovery and product quality. Metallurgical Technicians conduct laboratory tests and analyze metallurgical samples to monitor the chemical and physical properties of ores and concentrates, supporting process optimization and compliance with industry standards. Both roles require collaboration to troubleshoot process issues, maintain safety protocols, and improve mineral extraction efficiency throughout daily production cycles.

Required Qualifications and Skills

Mineral Processing Operators require a high school diploma or equivalent, with on-the-job training emphasizing equipment operation, safety protocols, and basic chemistry knowledge. Metallurgical Technicians typically hold a diploma or degree in metallurgy, chemical engineering, or mineral processing, equipped with advanced skills in laboratory analysis, process control, and metallurgical testing. Both roles demand strong problem-solving abilities and attention to detail, but Metallurgical Technicians often engage in complex data interpretation and process optimization.

Work Environments and Conditions

Mineral Processing Operators typically work on-site at mining plants, handling the machinery that crushes, grinds, and processes ores under physically demanding and noisy conditions. Metallurgical Technicians often operate in laboratory or pilot plant settings, conducting tests and experiments to improve metal extraction and refining processes in controlled environments. Both roles require strict adherence to safety protocols due to exposure to hazardous materials and the risk of industrial accidents in mining operations.

Tools and Technologies Used

Mineral Processing Operators utilize equipment such as crushers, grinders, flotation cells, and gravity separators to extract valuable minerals from ore, relying heavily on automated control systems and real-time data monitoring technologies. Metallurgical Technicians employ advanced analytical instruments including spectrometers, X-ray fluorescence (XRF) analyzers, and metallurgical microscopes to conduct material testing and quality control throughout the refining and smelting processes. Both roles integrate software tools for process simulation and optimization, but Metallurgical Technicians focus more on laboratory technologies to ensure compliance with metallurgical standards.

Training and Advancement Opportunities

Mineral Processing Operators typically undergo technical training programs focused on equipment operation, control systems, and safety protocols, enabling entry-level roles in processing plants. Metallurgical Technicians receive advanced education in metallurgy and materials science, often through diploma or degree programs, preparing them for analytical and process optimization tasks. Career advancement for Mineral Processing Operators can include supervisory roles, while Metallurgical Technicians have pathways toward specialized research, process development, and engineering positions within the mining industry.

Safety Protocols and Regulations

Mineral Processing Operators and Metallurgical Technicians both adhere to strict safety protocols governed by mining industry regulations such as MSHA and OSHA standards to prevent workplace hazards. Mineral Processing Operators focus on operational safety measures during ore crushing and grinding, while Metallurgical Technicians implement safety procedures in chemical testing and material analysis laboratories. Compliance with environmental and hazardous material handling regulations is mandatory for both roles to minimize risks and ensure a safe mining environment.

Common Challenges in Each Role

Mineral Processing Operators often face challenges such as maintaining consistent equipment performance and managing variations in ore quality to optimize extraction rates. Metallurgical Technicians encounter difficulties in analyzing complex metallurgical data and troubleshooting process inefficiencies to improve metal recovery and product purity. Both roles require precise monitoring and rapid problem-solving skills to ensure operational efficiency and compliance with safety and environmental standards.

Career Pathways and Promotion Prospects

Mineral Processing Operators typically focus on controlling and monitoring equipment to extract valuable minerals, often starting in entry-level roles with opportunities to advance into supervisory positions. Metallurgical Technicians possess specialized knowledge in testing and analyzing mineral samples, enabling career progression into technical expert roles or metallurgical engineering support. Both career paths offer strong promotion prospects, with Metallurgical Technicians frequently moving into research and development or process optimization, while Mineral Processing Operators often advance through operational management ranks.

Salary Expectations and Job Outlook

Mineral Processing Operators typically earn an average annual salary ranging from $50,000 to $70,000, with job growth projected at about 5% over the next decade due to steady demand in ore processing facilities. Metallurgical Technicians command higher salaries, often between $60,000 and $85,000, driven by specialized skills in analyzing and improving metal extraction processes, with job opportunities expanding around 6% as technological advancements in metallurgy increase. Both careers require specialized technical knowledge, but Metallurgical Technicians generally have stronger prospects for salary growth and employment stability in mining operations.

Mineral Processing Operator vs Metallurgical Technician Infographic

jobdiv.com

jobdiv.com