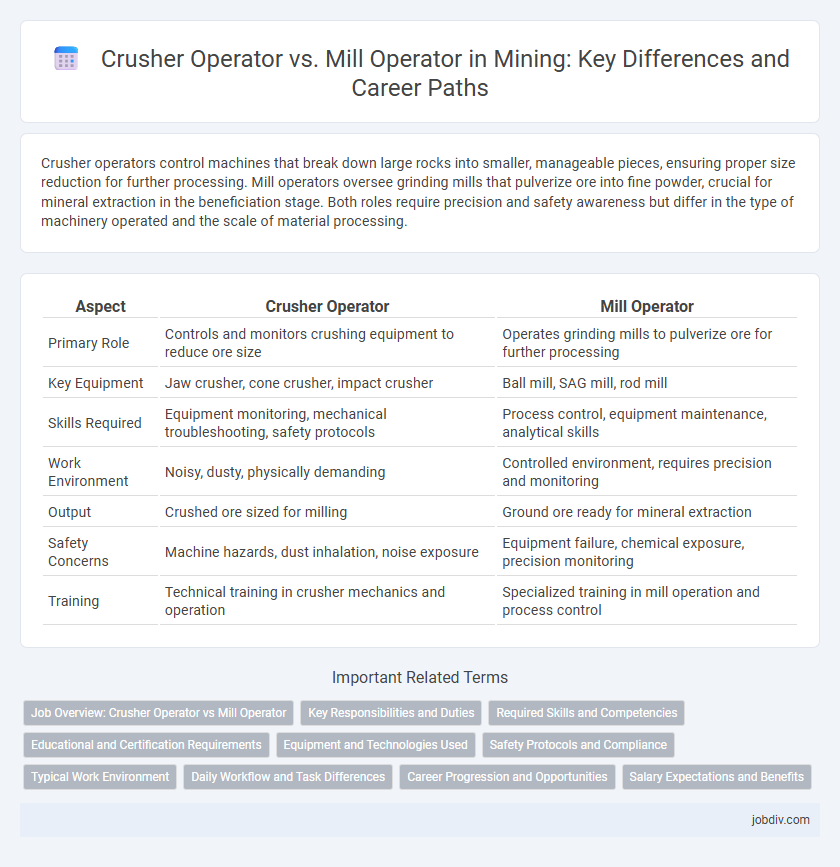

Crusher operators control machines that break down large rocks into smaller, manageable pieces, ensuring proper size reduction for further processing. Mill operators oversee grinding mills that pulverize ore into fine powder, crucial for mineral extraction in the beneficiation stage. Both roles require precision and safety awareness but differ in the type of machinery operated and the scale of material processing.

Table of Comparison

| Aspect | Crusher Operator | Mill Operator |

|---|---|---|

| Primary Role | Controls and monitors crushing equipment to reduce ore size | Operates grinding mills to pulverize ore for further processing |

| Key Equipment | Jaw crusher, cone crusher, impact crusher | Ball mill, SAG mill, rod mill |

| Skills Required | Equipment monitoring, mechanical troubleshooting, safety protocols | Process control, equipment maintenance, analytical skills |

| Work Environment | Noisy, dusty, physically demanding | Controlled environment, requires precision and monitoring |

| Output | Crushed ore sized for milling | Ground ore ready for mineral extraction |

| Safety Concerns | Machine hazards, dust inhalation, noise exposure | Equipment failure, chemical exposure, precision monitoring |

| Training | Technical training in crusher mechanics and operation | Specialized training in mill operation and process control |

Job Overview: Crusher Operator vs Mill Operator

Crusher Operators manage heavy machinery to reduce large rocks into smaller, manageable pieces for further processing, ensuring optimal equipment performance and safety. Mill Operators control grinding mills that pulverize ore to a fine consistency, critical for maximizing mineral extraction during beneficiation. Both roles require monitoring equipment parameters and performing routine maintenance to maintain production efficiency in mining operations.

Key Responsibilities and Duties

Crusher Operators control and monitor machinery that breaks down large rocks into smaller, manageable pieces, ensuring consistent material size for processing. Mill Operators oversee grinding mills that pulverize ore into fine particles, optimizing extraction efficiency and maintaining equipment performance. Both roles require strict adherence to safety protocols and operation logs to support overall mineral processing production.

Required Skills and Competencies

Crusher Operators require strong mechanical aptitude, proficiency in operating heavy machinery, and the ability to monitor equipment performance for optimal crushing processes. Mill Operators must possess in-depth knowledge of mineral processing techniques, skills in adjusting milling equipment settings, and competency in quality control to ensure efficient grinding and particle size reduction. Both roles demand attention to safety protocols, problem-solving skills, and the capability to perform maintenance and troubleshooting under mining site conditions.

Educational and Certification Requirements

Crusher operators typically require a high school diploma or equivalent, supplemented by on-the-job training and certifications such as OSHA safety training or equipment-specific licenses. Mill operators often need similar foundational education but may also pursue specialized technical courses or certifications in metallurgy, mineral processing, or mechanical systems to handle complex milling equipment. Both roles emphasize practical experience, with mill operators frequently requiring advanced knowledge in operating control systems and maintenance protocols.

Equipment and Technologies Used

Crusher operators utilize jaw crushers, cone crushers, and impact crushers equipped with hydraulic adjustment systems to break down large rocks into smaller, manageable pieces, often integrating sensors for real-time monitoring of equipment performance. Mill operators manage grinding mills such as SAG (Semi-Autogenous Grinding) mills and ball mills that use rotating drums and grinding media to pulverize ore into fine particles, employing automation technologies for precise control of grinding conditions and energy consumption. Both roles require expertise in advanced control systems and maintenance protocols to ensure efficient material processing and optimal throughput in mining operations.

Safety Protocols and Compliance

Crusher operators and mill operators both adhere strictly to safety protocols and compliance standards set by mining regulatory authorities, with crusher operators focusing on machine guarding and lockout/tagout procedures to prevent accidental startups. Mill operators prioritize confined space entry protocols and dust control measures to minimize respiratory hazards, while both roles require regular equipment inspections and emergency response training to ensure workplace safety. Adherence to Occupational Safety and Health Administration (OSHA) guidelines and Mine Safety and Health Administration (MSHA) regulations is mandatory to reduce injury risks and maintain operational efficiency.

Typical Work Environment

Crusher Operators work primarily in outdoor mining sites or processing plants where they control machinery that breaks down large rocks into smaller fragments, often exposed to dust, noise, and vibration. Mill Operators typically operate inside large, enclosed grinding mills in controlled environments, focusing on reducing ore size for further processing while managing temperature and humidity levels. Both roles require strict adherence to safety protocols due to the heavy machinery and potentially hazardous conditions surrounding their workspaces.

Daily Workflow and Task Differences

Crusher Operators manage the initial size reduction of ore by operating jaw, cone, or gyratory crushers, ensuring raw materials are properly fed and crushed to specifications. Mill Operators oversee grinding mills, controlling ball or SAG mills to further reduce ore particle size for extraction processes, monitoring variables like feed rate and mill speed. Daily workflows differ as Crusher Operators focus on handling coarse ore crushing and equipment maintenance, while Mill Operators concentrate on fine grinding performance and slurry consistency.

Career Progression and Opportunities

Crusher Operators typically begin their careers managing machinery that breaks down large rocks into smaller pieces, developing skills in equipment maintenance and safety protocols. Mill Operators advance by overseeing grinding mills that process ore, requiring deeper knowledge of chemical properties and production efficiency. Career progression often leads Crusher Operators to Mill Operator roles, with opportunities to specialize in process optimization or move into supervisory positions within mining site operations.

Salary Expectations and Benefits

Crusher Operators typically earn a median salary ranging from $45,000 to $60,000 annually, reflecting the physically demanding nature of managing heavy machinery used to break down large rocks. Mill Operators often receive higher compensation, averaging between $55,000 and $70,000 per year, due to their role in overseeing complex grinding processes and maintaining equipment precision for mineral extraction. Both positions commonly offer benefits such as health insurance, retirement plans, and paid time off, with Mill Operators sometimes receiving additional bonuses linked to production efficiency and safety performance.

Crusher Operator vs Mill Operator Infographic

jobdiv.com

jobdiv.com