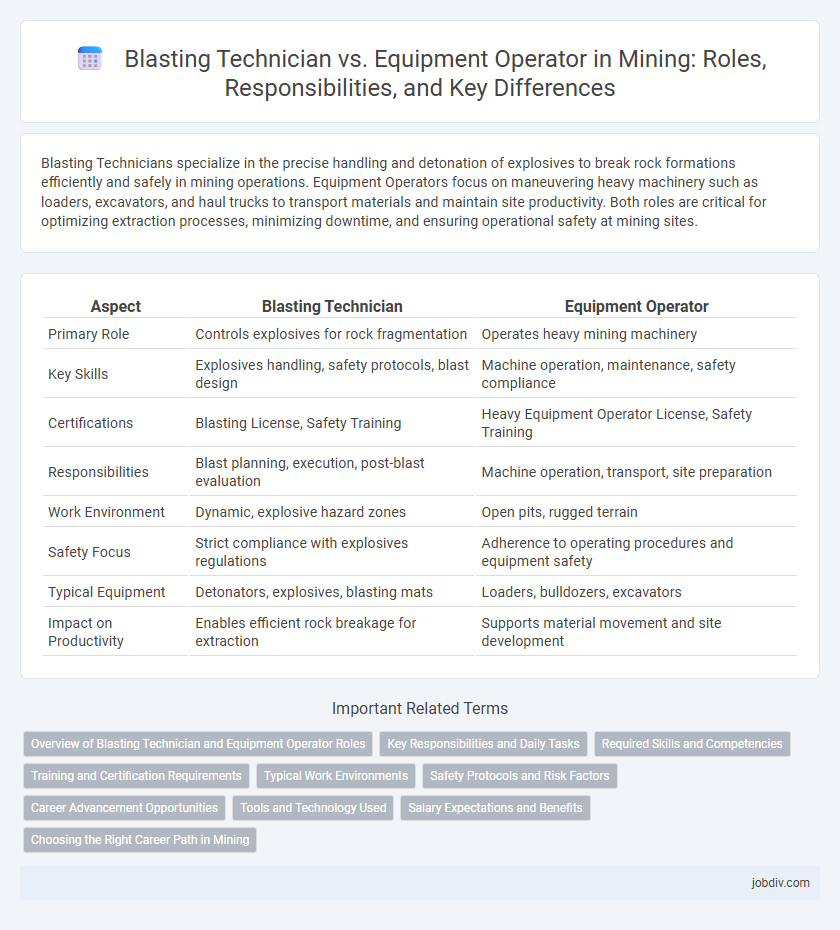

Blasting Technicians specialize in the precise handling and detonation of explosives to break rock formations efficiently and safely in mining operations. Equipment Operators focus on maneuvering heavy machinery such as loaders, excavators, and haul trucks to transport materials and maintain site productivity. Both roles are critical for optimizing extraction processes, minimizing downtime, and ensuring operational safety at mining sites.

Table of Comparison

| Aspect | Blasting Technician | Equipment Operator |

|---|---|---|

| Primary Role | Controls explosives for rock fragmentation | Operates heavy mining machinery |

| Key Skills | Explosives handling, safety protocols, blast design | Machine operation, maintenance, safety compliance |

| Certifications | Blasting License, Safety Training | Heavy Equipment Operator License, Safety Training |

| Responsibilities | Blast planning, execution, post-blast evaluation | Machine operation, transport, site preparation |

| Work Environment | Dynamic, explosive hazard zones | Open pits, rugged terrain |

| Safety Focus | Strict compliance with explosives regulations | Adherence to operating procedures and equipment safety |

| Typical Equipment | Detonators, explosives, blasting mats | Loaders, bulldozers, excavators |

| Impact on Productivity | Enables efficient rock breakage for extraction | Supports material movement and site development |

Overview of Blasting Technician and Equipment Operator Roles

Blasting Technicians specialize in the safe handling and detonation of explosives to fragment rock for easier extraction, ensuring compliance with safety regulations and precise blast designs. Equipment Operators manage heavy machinery such as loaders, excavators, and haul trucks to transport mined materials, maintain equipment efficiency, and support overall mining operations. Both roles are critical in optimizing productivity and safety in surface and underground mining environments.

Key Responsibilities and Daily Tasks

Blasting Technicians in mining are primarily responsible for designing, planning, and executing controlled explosions to break rock for easier extraction, ensuring safety compliance and precise charge placements. Equipment Operators focus on maneuvering heavy machinery such as drills, loaders, and haul trucks to transport and process mined materials efficiently within the site. Both roles require detailed knowledge of mining plans and safety protocols, but Blasting Technicians emphasize explosive handling, while Equipment Operators specialize in machinery operation and maintenance.

Required Skills and Competencies

Blasting Technicians require expertise in explosive materials, precise detonator placement, and adherence to safety protocols to ensure controlled fragmentation and minimize environmental impact. Equipment Operators must possess strong mechanical skills, the ability to operate heavy machinery such as drills, loaders, and trucks, and a keen sense of spatial awareness to maintain operational efficiency and safety on-site. Both roles demand rigorous training, attention to detail, and compliance with mining regulations to optimize productivity and reduce risks.

Training and Certification Requirements

Blasting technicians require specialized training in explosives handling, safety protocols, and regulatory compliance, often obtaining certifications such as the Certified Blaster Program or Mining Safety and Health Administration (MSHA) explosives licenses. Equipment operators must complete training programs tailored to specific heavy machinery, including hydraulic shovels, drills, and haul trucks, with certification provided through vocational schools or recognized mining safety organizations like MSHA. Both roles demand rigorous safety training, but blasting technicians face stricter regulatory standards due to the inherent risks of explosive materials.

Typical Work Environments

Blasting Technicians typically work in open-pit mines, quarries, or construction sites where they handle explosives to fracture rock for extraction. Equipment Operators are usually found in both surface and underground mines, operating heavy machinery such as haul trucks, loaders, and excavators. Both roles require adherence to strict safety protocols in dynamic, often harsh environments featuring dust, noise, and varying weather conditions.

Safety Protocols and Risk Factors

Blasting Technicians implement strict safety protocols involving precise explosive handling, risk assessment, and exclusion zones to prevent accidental detonations and ensure controlled blasts. Equipment Operators focus on machinery safety, maintaining secure operation of heavy equipment to minimize mechanical failures and operator injuries. Both roles require rigorous training and adherence to site-specific regulations to mitigate hazards associated with mining operations.

Career Advancement Opportunities

Blasting Technicians in mining often advance through specialized certifications such as explosives handling and safety management, enabling them to move into supervisory or consulting roles. Equipment Operators typically progress by gaining expertise in multiple machinery types, leading to positions like fleet supervisors or site managers. Both career paths offer strong upward mobility, but Blasting Technicians tend to have a niche advantage in regulatory compliance and risk management roles within the mining sector.

Tools and Technology Used

Blasting Technicians utilize specialized tools such as detonators, blasting machines, and electronic delay detonators to safely control explosive charges, ensuring precise fragmentation and controlled rock movement. Equipment Operators focus on operating heavy machinery like excavators, loaders, and haul trucks, relying on GPS systems and real-time monitoring technology to maximize efficiency and safety during material handling. Both roles integrate advanced technology to optimize mining operations, but Blasting Technicians emphasize explosive control instruments while Equipment Operators leverage heavy equipment with digital navigation aids.

Salary Expectations and Benefits

Blasting Technicians in mining typically earn higher salaries than Equipment Operators due to the specialized skills and certifications required for handling explosives safely, with average annual pay ranging from $65,000 to $90,000. Equipment Operators generally earn between $50,000 and $75,000 per year, benefiting from steady demand for machine operation and maintenance expertise. Benefits for both roles often include health insurance, retirement plans, and performance bonuses, though Blasting Technicians may receive additional hazard pay reflecting the risks involved.

Choosing the Right Career Path in Mining

Blasting Technicians specialize in designing and executing controlled explosions to fragment rock, requiring expertise in explosives safety and regulatory compliance. Equipment Operators handle heavy machinery like loaders and haul trucks, ensuring efficient material transport and site productivity. Choosing the right career path depends on your interest in precision technical skills versus machinery operation and your preference for dynamic, high-risk tasks or consistent machine handling.

Blasting Technician vs Equipment Operator Infographic

jobdiv.com

jobdiv.com