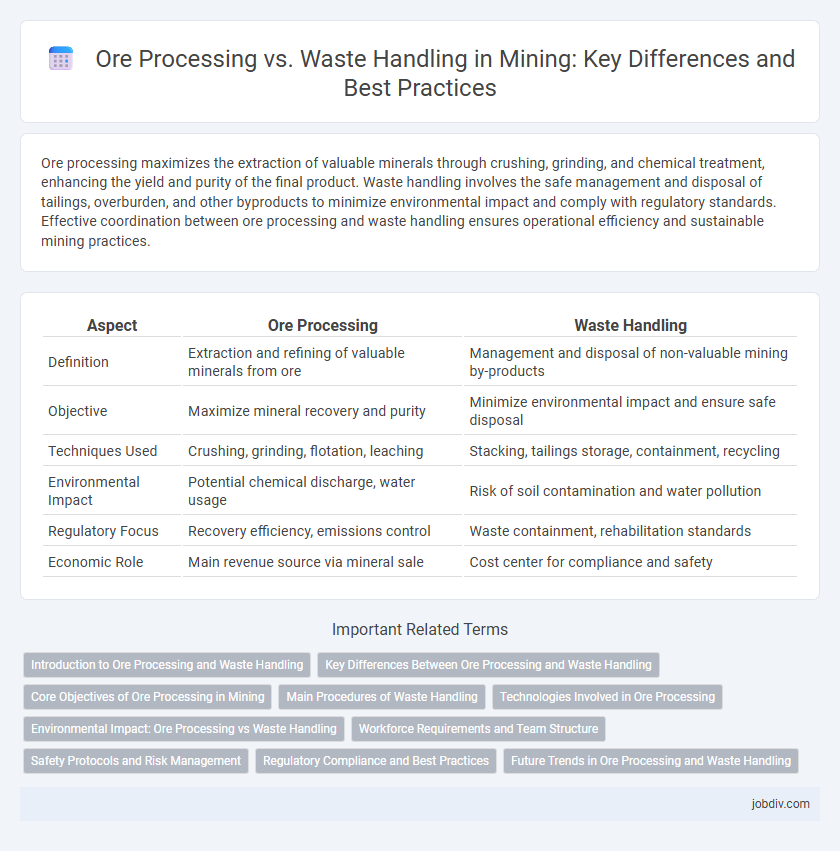

Ore processing maximizes the extraction of valuable minerals through crushing, grinding, and chemical treatment, enhancing the yield and purity of the final product. Waste handling involves the safe management and disposal of tailings, overburden, and other byproducts to minimize environmental impact and comply with regulatory standards. Effective coordination between ore processing and waste handling ensures operational efficiency and sustainable mining practices.

Table of Comparison

| Aspect | Ore Processing | Waste Handling |

|---|---|---|

| Definition | Extraction and refining of valuable minerals from ore | Management and disposal of non-valuable mining by-products |

| Objective | Maximize mineral recovery and purity | Minimize environmental impact and ensure safe disposal |

| Techniques Used | Crushing, grinding, flotation, leaching | Stacking, tailings storage, containment, recycling |

| Environmental Impact | Potential chemical discharge, water usage | Risk of soil contamination and water pollution |

| Regulatory Focus | Recovery efficiency, emissions control | Waste containment, rehabilitation standards |

| Economic Role | Main revenue source via mineral sale | Cost center for compliance and safety |

Introduction to Ore Processing and Waste Handling

Ore processing involves the extraction and refinement of valuable minerals from mined ore, utilizing techniques such as crushing, grinding, and flotation to maximize metal recovery efficiency. Waste handling in mining addresses the management of tailings, waste rock, and other by-products through methods like containment, stabilization, and recycling to minimize environmental impact. Effective integration of ore processing and waste handling practices enhances resource utilization while ensuring compliance with regulatory standards and sustainability goals.

Key Differences Between Ore Processing and Waste Handling

Ore processing involves extracting valuable minerals from mined ore through crushing, grinding, and separation techniques, maximizing resource recovery with minimal loss. Waste handling focuses on managing and disposing of non-valuable materials, such as tailings and overburden, using methods like containment, stabilization, and remediation to prevent environmental contamination. The key difference lies in ore processing targeting resource extraction and enrichment, whereas waste handling prioritizes environmental protection and regulatory compliance.

Core Objectives of Ore Processing in Mining

Ore processing in mining primarily aims to extract valuable minerals from raw ore, maximizing metal recovery rates while minimizing the loss of precious resources. This process enhances the economic value of the mined material by concentrating ore particles and removing impurities. Waste handling focuses on safely managing and disposing of non-valuable rock and tailings to reduce environmental impact and ensure regulatory compliance.

Main Procedures of Waste Handling

Waste handling in mining involves the systematic collection, transportation, and disposal of overburden, tailings, and other non-ore materials generated during ore extraction. Key procedures include segregation of waste types, stabilization of tailings through thickening or filtration, and secure storage in engineered waste repositories or tailings dams to prevent environmental contamination. Effective waste handling also requires continuous monitoring of leachates and structural integrity to minimize ecological and safety risks associated with mining operations.

Technologies Involved in Ore Processing

Ore processing technologies include crushing, grinding, magnetic separation, flotation, and leaching, which optimize the extraction of valuable minerals from the raw ore. Advanced equipment such as jaw crushers, ball mills, and flotation cells enhance mineral recovery efficiency while minimizing energy consumption. Automation and real-time monitoring systems improve process control, reduce operational costs, and ensure environmental compliance during ore beneficiation.

Environmental Impact: Ore Processing vs Waste Handling

Ore processing generates tailings and effluents containing heavy metals and chemicals, posing significant risks of soil and water contamination if not properly managed. Waste handling involves managing overburden and waste rock, which can lead to acid mine drainage and habitat destruction, affecting local biodiversity. Effective environmental management requires integrating ore processing controls and waste handling practices to minimize pollution and ecological harm in mining operations.

Workforce Requirements and Team Structure

Ore processing demands a workforce skilled in mineral separation techniques, equipment operation, and quality control, requiring specialized training and certifications. Waste handling teams prioritize environmental safety expertise and regulatory compliance, often involving collaboration between environmental engineers and field technicians. Optimal team structures integrate cross-disciplinary roles to enhance efficiency and maintain sustainable mining operations.

Safety Protocols and Risk Management

Ore processing involves rigorous safety protocols such as dust control, ventilation, and protective equipment to minimize exposure to hazardous minerals and airborne contaminants. Waste handling requires strict risk management measures, including secure tailings storage, regular monitoring for possible leakages or spills, and effective containment systems to prevent environmental contamination and worker exposure to toxic substances. Both processes demand continuous training, emergency preparedness, and compliance with regulatory standards to safeguard human health and environmental integrity in mining operations.

Regulatory Compliance and Best Practices

Ore processing and waste handling in mining require strict adherence to regulatory compliance to minimize environmental impact and ensure worker safety. Best practices involve implementing advanced filtration systems, regular monitoring of tailings storage facilities, and using sustainable chemical treatments to reduce hazardous waste. Compliance with regulations such as the Environmental Protection Agency (EPA) guidelines and the Mine Safety and Health Administration (MSHA) standards is essential for operational legitimacy and community protection.

Future Trends in Ore Processing and Waste Handling

Future trends in ore processing emphasize advanced automation, real-time data analytics, and eco-friendly technologies to enhance extraction efficiency and reduce environmental impact. Innovations in waste handling include the development of circular economy practices, such as tailings reuse and bioleaching, which minimize hazardous byproducts. The integration of AI-driven sorting and sensor-based separation systems further optimizes resource recovery while ensuring sustainable mining operations.

Ore Processing vs Waste Handling Infographic

jobdiv.com

jobdiv.com