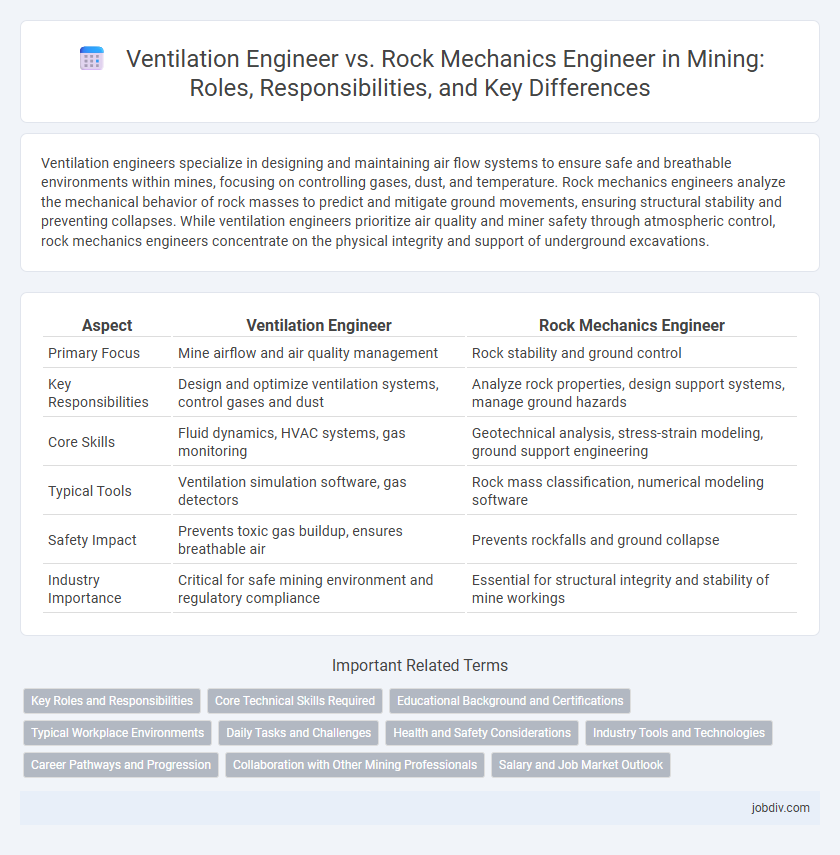

Ventilation engineers specialize in designing and maintaining air flow systems to ensure safe and breathable environments within mines, focusing on controlling gases, dust, and temperature. Rock mechanics engineers analyze the mechanical behavior of rock masses to predict and mitigate ground movements, ensuring structural stability and preventing collapses. While ventilation engineers prioritize air quality and miner safety through atmospheric control, rock mechanics engineers concentrate on the physical integrity and support of underground excavations.

Table of Comparison

| Aspect | Ventilation Engineer | Rock Mechanics Engineer |

|---|---|---|

| Primary Focus | Mine airflow and air quality management | Rock stability and ground control |

| Key Responsibilities | Design and optimize ventilation systems, control gases and dust | Analyze rock properties, design support systems, manage ground hazards |

| Core Skills | Fluid dynamics, HVAC systems, gas monitoring | Geotechnical analysis, stress-strain modeling, ground support engineering |

| Typical Tools | Ventilation simulation software, gas detectors | Rock mass classification, numerical modeling software |

| Safety Impact | Prevents toxic gas buildup, ensures breathable air | Prevents rockfalls and ground collapse |

| Industry Importance | Critical for safe mining environment and regulatory compliance | Essential for structural integrity and stability of mine workings |

Key Roles and Responsibilities

Ventilation Engineers specialize in designing and managing airflow systems to ensure safe and breathable air quality in underground mines, focusing on controlling gas emissions, dust levels, and temperature regulation. Rock Mechanics Engineers analyze rock behavior to evaluate ground stability, designing support systems to prevent collapses and optimize excavation methods based on geotechnical data. Both roles are critical for mine safety, with Ventilation Engineers prioritizing atmospheric control and Rock Mechanics Engineers emphasizing structural integrity.

Core Technical Skills Required

Ventilation engineers require expertise in air flow modeling, gas monitoring systems, and ventilation network design to ensure miner safety and regulatory compliance. Rock mechanics engineers specialize in geomechanics, stress analysis, and ground control techniques to assess and mitigate rock stability and support structures. Both roles demand proficiency in computational modeling software and an understanding of mine geology, but their core technical skills focus on distinct aspects of underground mine environment management.

Educational Background and Certifications

Ventilation Engineers typically hold degrees in mining, mechanical, or environmental engineering with specialized coursework in airflow dynamics, air quality, and mine ventilation systems, often pursuing certifications such as the Mine Ventilation Society Professional Qualification or Certified Mining Engineer credentials. Rock Mechanics Engineers generally possess degrees in geological, mining, or civil engineering, focusing on geomechanics, rock behavior, and ground control, with certifications like the International Society for Rock Mechanics (ISRM) Professional Engineer or equivalent specialized training. Both roles demand strong foundations in engineering principles, but their distinct educational paths and certifications align with their specific mine safety and operational responsibilities.

Typical Workplace Environments

Ventilation Engineers typically work in underground mines, control rooms, and surface facilities, focusing on air quality and airflow management to ensure safe breathing conditions. Rock Mechanics Engineers are primarily based in underground tunnels, mine shafts, and geotechnical offices, analyzing rock stability and ground control to prevent collapses. Both roles require field inspections and collaboration with multidisciplinary teams in often harsh, confined, and hazardous mining environments.

Daily Tasks and Challenges

Ventilation Engineers monitor and optimize airflow systems to ensure safe and breathable environments in underground mines, addressing challenges like gas removal and temperature control. Rock Mechanics Engineers analyze rock stability and design support structures to prevent collapses, facing difficulties related to unpredictable geological conditions and stress distributions. Both roles require constant data analysis and adaptation to dynamic underground environments to maintain miner safety and operational efficiency.

Health and Safety Considerations

Ventilation Engineers prioritize maintaining air quality by controlling dust, gas levels, and temperature to prevent respiratory hazards and explosive atmospheres in mines. Rock Mechanics Engineers focus on assessing ground stability and stress distribution to prevent collapses and rock bursts, ensuring structural safety for miners. Both roles are critical for comprehensive health and safety management, combining atmospheric control with geological risk mitigation.

Industry Tools and Technologies

Ventilation Engineers utilize advanced gas monitoring systems, computational fluid dynamics (CFD) software, and real-time air quality sensors to optimize underground airflow and ensure miner safety. Rock Mechanics Engineers employ geotechnical modeling tools, numerical simulation software like FLAC3D, and ground support monitoring devices to analyze rock stability and design effective support systems. Both roles integrate IoT-enabled equipment and data analytics platforms to enhance operational efficiency and safety in mining environments.

Career Pathways and Progression

Ventilation Engineers in mining specialize in designing and managing airflow systems to ensure safety and regulatory compliance, advancing towards roles like Chief Ventilation Officer or Environmental Health and Safety Manager. Rock Mechanics Engineers focus on analyzing and stabilizing rock formations, progressing into Senior Geotechnical Engineer or Mine Planning Manager positions. Both career pathways offer growth through technical expertise, project leadership, and cross-disciplinary integration within mining operations.

Collaboration with Other Mining Professionals

Ventilation engineers and rock mechanics engineers collaborate closely to ensure mine safety and operational efficiency by integrating air quality management with ground stability analysis. They share critical data on airflow patterns and stress distribution to optimize ventilation systems and support structures, reducing risks of hazardous gas accumulation and ground failure. Effective communication between these professionals enhances real-time decision-making and comprehensive mining system design.

Salary and Job Market Outlook

Ventilation Engineers specializing in mine airflow design earn an average salary of $85,000 to $105,000 annually, with demand driven by safety regulations and increasing mining operations. Rock Mechanics Engineers typically command higher salaries ranging from $95,000 to $120,000 due to their expertise in ground control and stability analysis, critical for deep mining projects. The job market outlook favors Rock Mechanics Engineers slightly more, as complex mining environments require advanced geotechnical assessments to mitigate risks and optimize extraction processes.

Ventilation Engineer vs Rock Mechanics Engineer Infographic

jobdiv.com

jobdiv.com