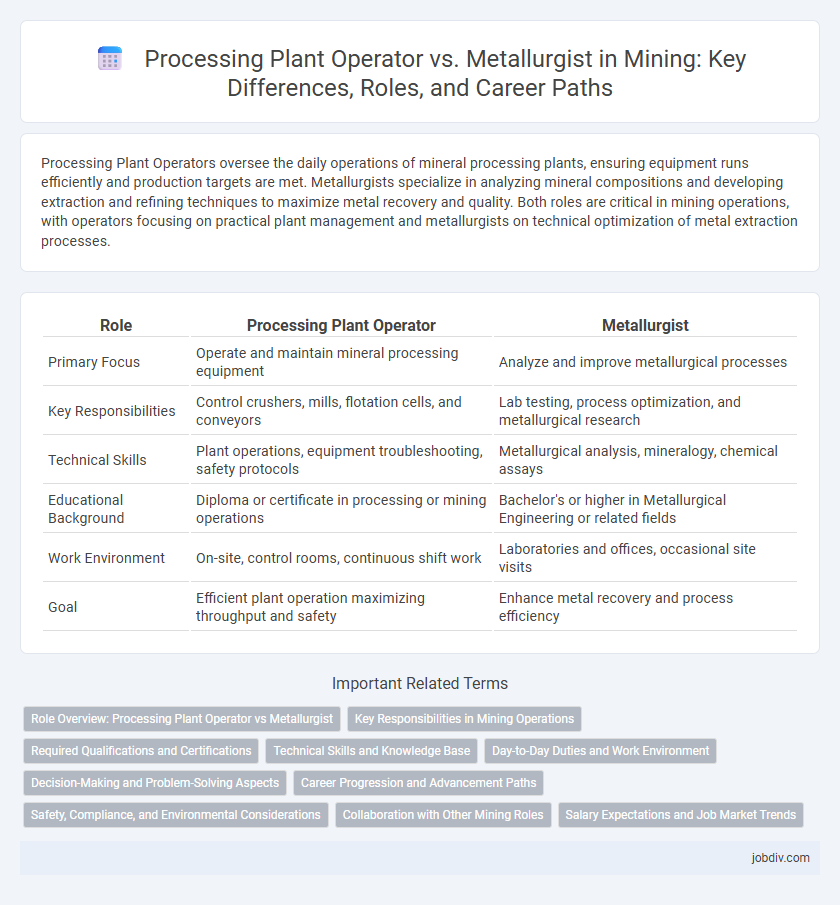

Processing Plant Operators oversee the daily operations of mineral processing plants, ensuring equipment runs efficiently and production targets are met. Metallurgists specialize in analyzing mineral compositions and developing extraction and refining techniques to maximize metal recovery and quality. Both roles are critical in mining operations, with operators focusing on practical plant management and metallurgists on technical optimization of metal extraction processes.

Table of Comparison

| Role | Processing Plant Operator | Metallurgist |

|---|---|---|

| Primary Focus | Operate and maintain mineral processing equipment | Analyze and improve metallurgical processes |

| Key Responsibilities | Control crushers, mills, flotation cells, and conveyors | Lab testing, process optimization, and metallurgical research |

| Technical Skills | Plant operations, equipment troubleshooting, safety protocols | Metallurgical analysis, mineralogy, chemical assays |

| Educational Background | Diploma or certificate in processing or mining operations | Bachelor's or higher in Metallurgical Engineering or related fields |

| Work Environment | On-site, control rooms, continuous shift work | Laboratories and offices, occasional site visits |

| Goal | Efficient plant operation maximizing throughput and safety | Enhance metal recovery and process efficiency |

Role Overview: Processing Plant Operator vs Metallurgist

Processing Plant Operators manage the day-to-day operations of mineral processing equipment, ensuring efficient extraction and adherence to safety protocols. Metallurgists focus on analyzing ore properties, developing extraction techniques, and optimizing metallurgical processes to maximize yield and quality. Both roles are critical in mining operations, with operators executing the processing stage and metallurgists designing and improving recovery methods.

Key Responsibilities in Mining Operations

Processing Plant Operators manage the daily operation of mineral processing equipment, ensuring optimal performance and adherence to safety protocols. Metallurgists analyze ore samples, design processing methods, and optimize the extraction of valuable metals through laboratory testing and process control. Both roles collaboratively enhance recovery rates and improve overall efficiency in mining operations.

Required Qualifications and Certifications

Processing Plant Operators typically require a high school diploma or equivalent, with specialized training in plant operations and safety certifications such as OSHA or MSHA compliance. Metallurgists usually hold a Bachelor's degree in Metallurgical or Materials Engineering, often complemented by professional certifications like Chartered Engineer (CEng) or membership in the Metallurgical Society. Advanced knowledge of mineral processing techniques and proficiency in laboratory analysis distinguish metallurgists from plant operators, highlighting the more technical and scientific qualifications needed for metallurgical roles.

Technical Skills and Knowledge Base

Processing Plant Operators specialize in managing and controlling equipment used in mineral extraction, emphasizing practical skills in machinery operation, troubleshooting, and safety protocols. Metallurgists possess in-depth knowledge of metal properties, extraction techniques, and material testing, focusing on optimizing recovery processes through chemical and physical analysis. Both roles require expertise in mineral processing, but Processing Plant Operators prioritize operational control while Metallurgists concentrate on metallurgical testing and process optimization.

Day-to-Day Duties and Work Environment

Processing Plant Operators monitor and control machinery that processes raw minerals, ensuring efficient and safe operations within the plant environment. Metallurgists analyze the physical and chemical properties of metals, develop extraction techniques, and optimize metal quality through laboratory testing and field research. Both roles require collaboration with engineering teams, but Processing Plant Operators spend more time on-site managing equipment, while Metallurgists often divide time between labs and operational areas.

Decision-Making and Problem-Solving Aspects

Processing Plant Operators make real-time decisions controlling machinery to maintain optimal mineral extraction and ensure safety compliance. Metallurgists apply advanced scientific knowledge to analyze ore properties and develop processing methods, solving complex metallurgical problems to enhance metal recovery. Both roles require critical problem-solving skills, but Operators focus on operational adjustments while Metallurgists concentrate on technical innovations and process optimization.

Career Progression and Advancement Paths

Processing Plant Operators typically start their careers managing day-to-day operations of mineral processing equipment, gaining hands-on experience before advancing to supervisory roles or specialized technician positions. Metallurgists often pursue advanced education in metallurgy or materials science, enabling progression into project management, research and development, or senior technical advisory roles within mining companies. Career advancement for Processing Plant Operators leans towards operational leadership, while Metallurgists focus on innovation, process optimization, and strategic development.

Safety, Compliance, and Environmental Considerations

Processing Plant Operators maintain strict adherence to safety protocols and regulatory compliance by monitoring equipment performance and controlling hazardous materials within mining operations. Metallurgists drive environmental sustainability through metallurgical testing and ore refining processes, ensuring waste reduction and efficient resource utilization. Both roles collaborate to uphold industry standards, minimizing environmental impact and promoting a safe workplace in mining processing plants.

Collaboration with Other Mining Roles

Processing Plant Operators coordinate closely with Mining Engineers and Maintenance Technicians to ensure equipment efficiency and continuous ore processing. Metallurgists collaborate with Geologists and Quality Control specialists to analyze mineral samples and optimize extraction methods. Both roles require seamless communication to align operational processes with metallurgical testing results for improved resource recovery.

Salary Expectations and Job Market Trends

Processing Plant Operators typically earn between $50,000 and $75,000 annually, with steady demand driven by continuous ore processing needs in mining operations. Metallurgists command higher salaries, often ranging from $70,000 to $110,000, reflecting specialized expertise in metal extraction and refining techniques. Job market trends indicate growing opportunities for Metallurgists due to advancements in metallurgical technology and sustainable mining practices, while Processing Plant Operators experience consistent but more stable employment prospects.

Processing Plant Operator vs Metallurgist Infographic

jobdiv.com

jobdiv.com