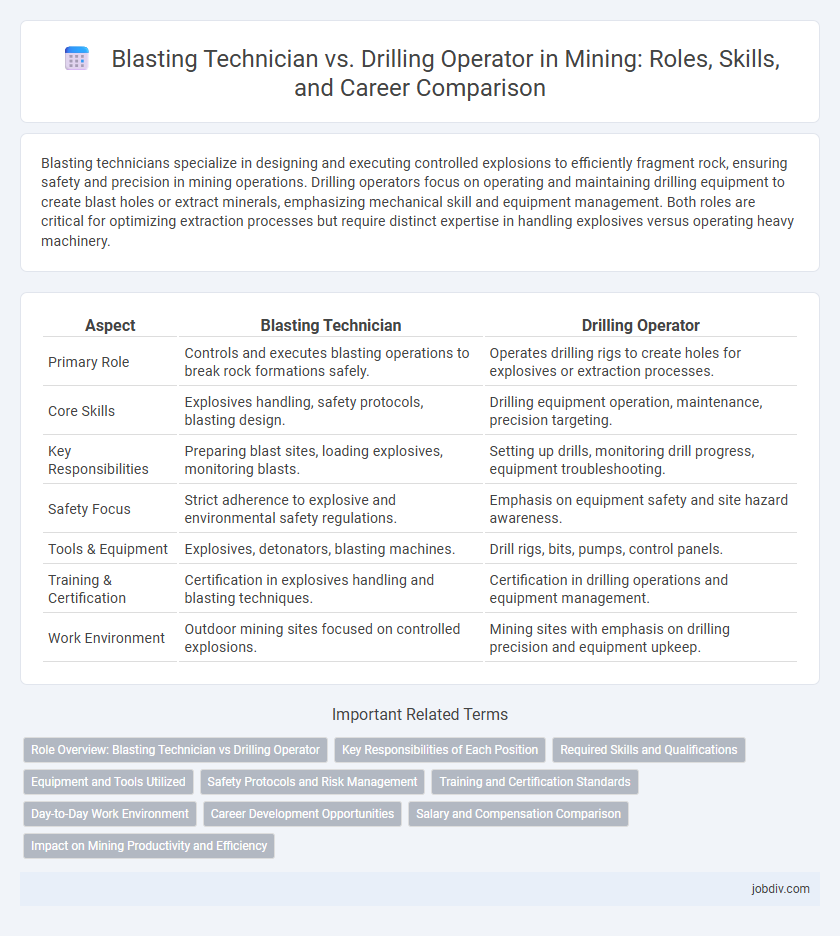

Blasting technicians specialize in designing and executing controlled explosions to efficiently fragment rock, ensuring safety and precision in mining operations. Drilling operators focus on operating and maintaining drilling equipment to create blast holes or extract minerals, emphasizing mechanical skill and equipment management. Both roles are critical for optimizing extraction processes but require distinct expertise in handling explosives versus operating heavy machinery.

Table of Comparison

| Aspect | Blasting Technician | Drilling Operator |

|---|---|---|

| Primary Role | Controls and executes blasting operations to break rock formations safely. | Operates drilling rigs to create holes for explosives or extraction processes. |

| Core Skills | Explosives handling, safety protocols, blasting design. | Drilling equipment operation, maintenance, precision targeting. |

| Key Responsibilities | Preparing blast sites, loading explosives, monitoring blasts. | Setting up drills, monitoring drill progress, equipment troubleshooting. |

| Safety Focus | Strict adherence to explosive and environmental safety regulations. | Emphasis on equipment safety and site hazard awareness. |

| Tools & Equipment | Explosives, detonators, blasting machines. | Drill rigs, bits, pumps, control panels. |

| Training & Certification | Certification in explosives handling and blasting techniques. | Certification in drilling operations and equipment management. |

| Work Environment | Outdoor mining sites focused on controlled explosions. | Mining sites with emphasis on drilling precision and equipment upkeep. |

Role Overview: Blasting Technician vs Drilling Operator

Blasting Technicians specialize in designing and executing explosive charges to safely fragment rock, ensuring optimal blast patterns and minimizing environmental impact. Drilling Operators handle the operation and maintenance of drilling rigs, focusing on precise borehole creation for ore extraction or blast hole placement. Both roles are critical in mining efficiency, with Blasting Technicians emphasizing controlled explosions and Drilling Operators concentrating on accurate and safe drilling processes.

Key Responsibilities of Each Position

Blasting Technicians specialize in designing and executing controlled explosive blasts to break rock formations, ensuring safety protocols and regulatory compliance are strictly followed. Drilling Operators are responsible for operating drilling rigs, maintaining equipment, and accurately drilling boreholes for mineral extraction based on geological data. Both roles require precision and expertise to optimize extraction efficiency and minimize environmental impact in mining operations.

Required Skills and Qualifications

Blasting Technicians require in-depth knowledge of explosives, safety regulations, and precise timing to ensure controlled detonations, along with certifications in explosive handling and risk assessment. Drilling Operators must possess expertise in operating and maintaining drilling machinery, understanding geological data, and mechanical troubleshooting skills, often supported by technical diplomas in mining or mechanical engineering. Both roles demand strong adherence to safety protocols, situational awareness, and effective communication to coordinate mining operations efficiently.

Equipment and Tools Utilized

Blasting Technicians specialize in handling explosives and detonators, using precise blasting machines, electronic delay detonators, and safety monitoring equipment to control rock fragmentation. Drilling Operators operate heavy machinery such as rotary drills, jumbo drills, and drill rigs, focusing on creating blast holes with accurate depth and diameter for subsequent blasting operations. Both roles require advanced knowledge of explosives and mining equipment, but Blasting Technicians emphasize explosive handling tools, while Drilling Operators focus on mechanical drilling equipment.

Safety Protocols and Risk Management

Blasting Technicians implement controlled explosive detonation following stringent safety protocols to minimize airborne debris and vibration hazards, emphasizing precise timing and secure exclusion zones. Drilling Operators focus on maintaining equipment integrity and operational accuracy, actively managing risks related to mechanical failures, dust exposure, and ground stability to safeguard personnel. Both roles require rigorous adherence to site-specific risk assessments and continuous monitoring to prevent accidents and ensure regulatory compliance in mining environments.

Training and Certification Standards

Blasting Technicians require specialized training on explosive handling, detonation procedures, and compliance with safety regulations governed by agencies such as MSHA or OSHA. Drilling Operators undergo certification focused on operating heavy drilling machinery, understanding geological formations, and adhering to environmental standards, often certified through industry-recognized programs like NCCER or state-specific licenses. Both roles mandate rigorous ongoing training to maintain certification, emphasizing risk management and technological proficiency in mining operations.

Day-to-Day Work Environment

Blasting Technicians in mining manage explosive materials to safely break rock formations, working closely with safety protocols and monitoring blast results in open pit or underground environments. Drilling Operators control heavy drilling machinery to create precise boreholes for explosives placement, often operating in challenging terrain with varying noise levels and vibration exposure. Both roles require strict adherence to safety standards, but Blasting Technicians focus on explosive handling while Drilling Operators emphasize machinery operation and maintenance.

Career Development Opportunities

Blasting Technicians specialize in explosive handling and design, offering career growth into senior blasting supervision, mine safety management, and explosive engineering roles. Drilling Operators possess expertise in operating and maintaining drilling equipment, enabling advancement toward drill rig management, mine planning, and technical advisory positions. Both careers provide pathways to advanced mining operations leadership and specialized technical consultancy within the extraction industry.

Salary and Compensation Comparison

Blasting Technicians typically earn an average salary ranging from $55,000 to $85,000 per year, reflecting their specialized skill in handling explosives and ensuring safe blast designs. Drilling Operators generally receive compensation between $60,000 and $90,000 annually, influenced by the complexity of drilling equipment and maintenance responsibilities. Salary variations depend on experience, location, and company size, with Drilling Operators often commanding slightly higher wages due to technical proficiency and operational demands.

Impact on Mining Productivity and Efficiency

Blasting technicians optimize rock fragmentation through precise explosive placement, directly enhancing ore extraction rates and reducing secondary breakage costs. Drilling operators contribute by accurately creating blast holes with consistent depth and angle, ensuring uniform fragmentation and minimizing equipment wear. Together, their coordination significantly increases mining productivity and operational efficiency by streamlining fragmentation and material handling.

Blasting Technician vs Drilling Operator Infographic

jobdiv.com

jobdiv.com