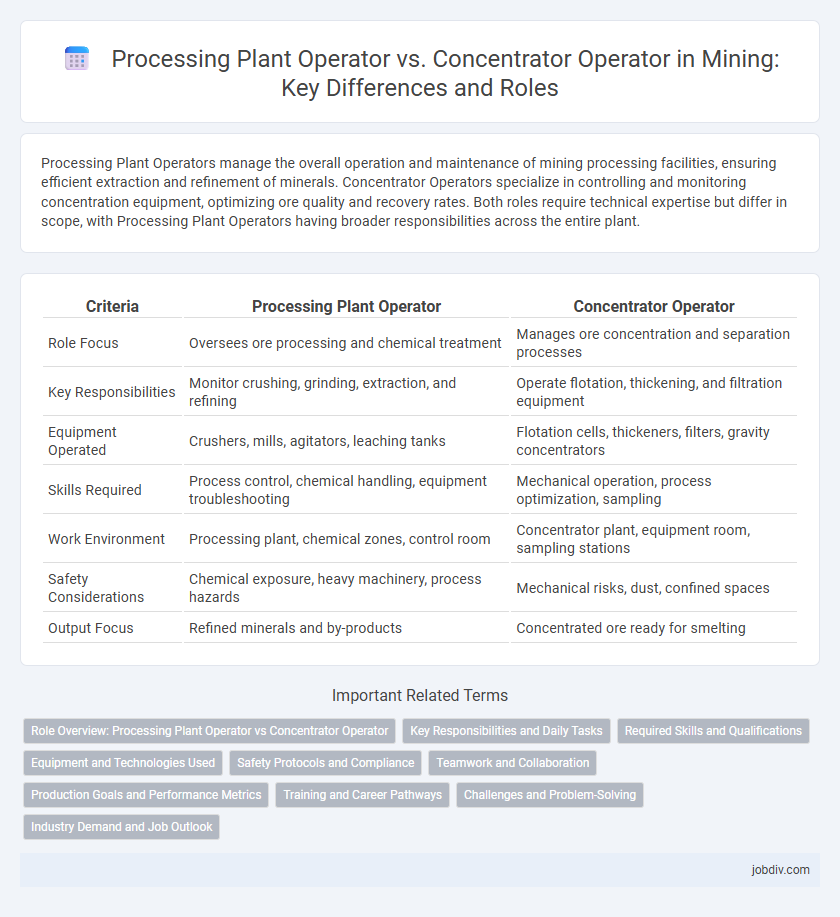

Processing Plant Operators manage the overall operation and maintenance of mining processing facilities, ensuring efficient extraction and refinement of minerals. Concentrator Operators specialize in controlling and monitoring concentration equipment, optimizing ore quality and recovery rates. Both roles require technical expertise but differ in scope, with Processing Plant Operators having broader responsibilities across the entire plant.

Table of Comparison

| Criteria | Processing Plant Operator | Concentrator Operator |

|---|---|---|

| Role Focus | Oversees ore processing and chemical treatment | Manages ore concentration and separation processes |

| Key Responsibilities | Monitor crushing, grinding, extraction, and refining | Operate flotation, thickening, and filtration equipment |

| Equipment Operated | Crushers, mills, agitators, leaching tanks | Flotation cells, thickeners, filters, gravity concentrators |

| Skills Required | Process control, chemical handling, equipment troubleshooting | Mechanical operation, process optimization, sampling |

| Work Environment | Processing plant, chemical zones, control room | Concentrator plant, equipment room, sampling stations |

| Safety Considerations | Chemical exposure, heavy machinery, process hazards | Mechanical risks, dust, confined spaces |

| Output Focus | Refined minerals and by-products | Concentrated ore ready for smelting |

Role Overview: Processing Plant Operator vs Concentrator Operator

Processing Plant Operators manage the overall operation, maintenance, and control of the entire mineral processing plant, ensuring optimal equipment performance and safety compliance. Concentrator Operators focus specifically on the concentrator section, handling ore grinding, flotation, and separation processes to maximize mineral recovery and product quality. Both roles require technical expertise in process control and equipment monitoring, but concentrator operators specialize in refining ore through physical and chemical concentration methods.

Key Responsibilities and Daily Tasks

Processing Plant Operators manage the operation and maintenance of equipment that transforms raw minerals into usable products, ensuring optimal efficiency and safety throughout the processing stages. Concentrator Operators specialize in controlling and adjusting flotation cells, thickeners, and dewatering equipment to maximize the concentration of valuable minerals while minimizing waste. Both roles require monitoring process variables, conducting routine inspections, troubleshooting mechanical issues, and adhering to strict environmental and safety regulations.

Required Skills and Qualifications

Processing Plant Operators require strong knowledge of mineral processing equipment, process control, and safety protocols, often holding certifications in mechanical or chemical processing. Concentrator Operators must possess expertise in flotation techniques, ore characterization, and skilled operation of concentrator machinery, complemented by hands-on experience in metallurgical processes. Both roles demand proficiency in monitoring plant performance, troubleshooting equipment malfunctions, and adhering to environmental and safety regulations specific to mining operations.

Equipment and Technologies Used

Processing Plant Operators manage equipment such as crushers, grinders, and flotation cells to ensure efficient ore extraction and material handling. Concentrator Operators specialize in advanced separation technologies, including thickeners, filters, and magnetic separators, optimizing the concentration of valuable minerals from ore. Both roles require proficiency in process control systems and maintenance of automated machinery to maximize mineral recovery and operational efficiency.

Safety Protocols and Compliance

Processing Plant Operators and Concentrator Operators adhere strictly to safety protocols such as lockout/tagout procedures, personal protective equipment (PPE) use, and hazardous material handling to prevent accidents. Compliance with environmental and workplace regulations like MSHA (Mine Safety and Health Administration) standards is critical to maintaining safe operational conditions in both roles. Regular safety audits, risk assessments, and emergency response drills are fundamental practices ensuring continuous adherence to safety requirements and regulatory compliance in mining operations.

Teamwork and Collaboration

Processing Plant Operators and Concentrator Operators play complementary roles in mining operations, requiring seamless teamwork to maintain efficient throughput and mineral recovery. Effective collaboration ensures synchronization between ore processing stages, minimizing downtime and optimizing equipment performance. Clear communication and coordinated problem-solving among these operators are essential to meet production targets and maintain safety standards.

Production Goals and Performance Metrics

Processing Plant Operators and Concentrator Operators both play critical roles in achieving mining production goals, with Processing Plant Operators managing equipment that transforms ore into marketable products. Concentrator Operators focus on optimizing ore concentration processes to enhance mineral recovery rates and reduce waste, directly impacting overall plant efficiency. Performance metrics for both roles include throughput rates, recovery percentages, and adherence to safety and environmental standards essential for sustainable mining operations.

Training and Career Pathways

Processing Plant Operators undergo specialized training in equipment handling, chemical processes, and safety protocols for ore processing facilities, enabling them to manage crushing, grinding, and smelting operations efficiently. Concentrator Operators receive targeted instruction on mineral separation techniques, flotation cells, and density separation, which equips them to optimize ore concentration and quality. Both career pathways offer advancement opportunities through gaining certifications in metallurgical processes and supervisory skills, facilitating progression into senior operational or management roles within the mining sector.

Challenges and Problem-Solving

Processing Plant Operators face challenges in monitoring complex machinery and ensuring continuous operation under variable ore quality, requiring strong troubleshooting skills to minimize downtime. Concentrator Operators encounter difficulties in optimizing mineral recovery rates and managing process fluctuations, demanding precise control and quick adjustments to maintain efficiency. Both roles necessitate problem-solving expertise to address equipment malfunctions and adapt to changing feed conditions in high-pressure environments.

Industry Demand and Job Outlook

The demand for Processing Plant Operators and Concentrator Operators remains robust within the mining sector, driven by increased mineral exploration and production activities. Processing Plant Operators manage the overall operations of mineral processing facilities, while Concentrator Operators specialize in separating valuable minerals from ore, with both roles requiring strong technical skills and adherence to safety protocols. Job prospects are favorable, particularly in resource-rich regions, as advancements in automation and processing technologies create a need for operators skilled in monitoring and optimizing plant efficiency.

Processing Plant Operator vs Concentrator Operator Infographic

jobdiv.com

jobdiv.com