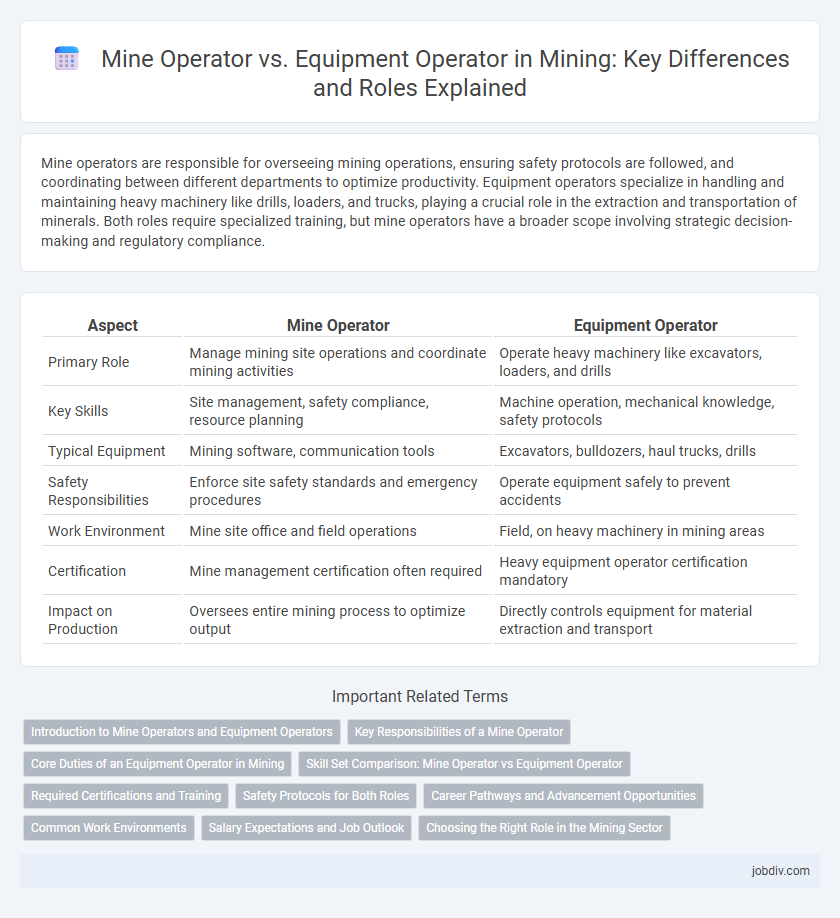

Mine operators are responsible for overseeing mining operations, ensuring safety protocols are followed, and coordinating between different departments to optimize productivity. Equipment operators specialize in handling and maintaining heavy machinery like drills, loaders, and trucks, playing a crucial role in the extraction and transportation of minerals. Both roles require specialized training, but mine operators have a broader scope involving strategic decision-making and regulatory compliance.

Table of Comparison

| Aspect | Mine Operator | Equipment Operator |

|---|---|---|

| Primary Role | Manage mining site operations and coordinate mining activities | Operate heavy machinery like excavators, loaders, and drills |

| Key Skills | Site management, safety compliance, resource planning | Machine operation, mechanical knowledge, safety protocols |

| Typical Equipment | Mining software, communication tools | Excavators, bulldozers, haul trucks, drills |

| Safety Responsibilities | Enforce site safety standards and emergency procedures | Operate equipment safely to prevent accidents |

| Work Environment | Mine site office and field operations | Field, on heavy machinery in mining areas |

| Certification | Mine management certification often required | Heavy equipment operator certification mandatory |

| Impact on Production | Oversees entire mining process to optimize output | Directly controls equipment for material extraction and transport |

Introduction to Mine Operators and Equipment Operators

Mine operators oversee underground and surface mining operations, ensuring safety protocols, regulatory compliance, and efficient resource extraction. Equipment operators specialize in handling heavy machinery such as excavators, haul trucks, and drills, directly impacting productivity and operational efficiency. Both roles require technical expertise, rigorous training, and coordination to maximize mine output and maintain workplace safety.

Key Responsibilities of a Mine Operator

A Mine Operator oversees the entire mining site operations, including planning, coordinating extraction processes, and ensuring compliance with safety and environmental regulations. They manage resources, supervise equipment operators, and monitor production targets to optimize efficiency. Unlike equipment operators who focus on handling machinery, mine operators are responsible for strategic decision-making and operational leadership within the mining environment.

Core Duties of an Equipment Operator in Mining

Equipment Operators in mining are responsible for operating heavy machinery such as excavators, bulldozers, and haul trucks to extract and transport minerals safely and efficiently. Their core duties include performing routine equipment inspections, troubleshooting mechanical issues, and adhering to safety protocols to minimize downtime and prevent accidents. Proficiency in operating specialized mining equipment and maintaining communication with the mine operator and ground crew ensures seamless coordination in mining operations.

Skill Set Comparison: Mine Operator vs Equipment Operator

Mine Operators possess a deep understanding of geological formations, mining techniques, and safety protocols, enabling them to oversee extraction processes effectively. Equipment Operators specialize in maneuvering heavy machinery such as bulldozers, excavators, and loaders with precision, requiring advanced mechanical skills and operational expertise. Both roles demand strong problem-solving abilities and adherence to safety standards, but Mine Operators emphasize strategic planning while Equipment Operators focus on technical machinery handling.

Required Certifications and Training

Mine Operators must obtain certifications such as the Mine Safety and Health Administration (MSHA) Part 46 or Part 48 training, which covers site-specific safety protocols and hazard recognition. Equipment Operators require specialized training and licensing for operating heavy machinery, including haul trucks, loaders, and drills, often necessitating a Commercial Driver's License (CDL) or equivalent certification. Both roles demand ongoing safety training and compliance with federal and state mining regulations to ensure workplace safety and operational efficiency.

Safety Protocols for Both Roles

Mine operators and equipment operators both play crucial roles in mining safety, with mine operators responsible for overseeing overall site safety protocols and ensuring compliance with regulatory standards like MSHA regulations. Equipment operators focus on the safe handling and maintenance of heavy machinery, following strict operational guidelines to prevent accidents and equipment malfunctions. Both roles require rigorous training in hazard recognition, emergency response procedures, and the use of personal protective equipment (PPE) to minimize risks associated with mining operations.

Career Pathways and Advancement Opportunities

Mine operators typically oversee entire mining operations, managing workflows, safety protocols, and regulatory compliance, while equipment operators specialize in handling and maintaining heavy machinery like bulldozers, excavators, and drills. Career pathways for mine operators often lead to senior management roles, such as operations manager or safety director, leveraging leadership and strategic planning skills. Equipment operators can advance by gaining certifications and expertise in specialized machinery, progressing to supervisory roles or transitioning into technical maintenance and training positions within mining organizations.

Common Work Environments

Mine operators and equipment operators commonly work in underground and surface mining environments where safety and precision are critical. Mine operators oversee the entire mining operation, often managing ventilation, extraction processes, and compliance with safety regulations, while equipment operators focus on maneuvering heavy machinery like loaders, drills, and haul trucks within the mine site. Both roles require adaptability to harsh conditions such as dust, noise, and confined spaces, with extensive use of protective gear and adherence to strict operational protocols.

Salary Expectations and Job Outlook

Mine operators typically earn higher salaries than equipment operators due to their broader responsibilities overseeing mining processes and safety compliance. Equipment operators, specializing in maneuvering heavy machinery like excavators and loaders, have a steady job outlook fueled by ongoing demand in surface and underground mining. Both roles benefit from competitive wages, with mine operators averaging around $70,000 annually and equipment operators earning approximately $50,000 to $60,000, reflecting industry demand and skill requirements.

Choosing the Right Role in the Mining Sector

Selecting the right role in the mining sector hinges on understanding the distinct responsibilities of a Mine Operator versus an Equipment Operator. Mine Operators oversee extraction processes and ensure operational safety, while Equipment Operators specialize in handling and maintaining heavy machinery such as excavators and loaders. Aligning personal skills with job demands enhances efficiency, safety compliance, and career growth within mining operations.

Mine Operator vs Equipment Operator Infographic

jobdiv.com

jobdiv.com