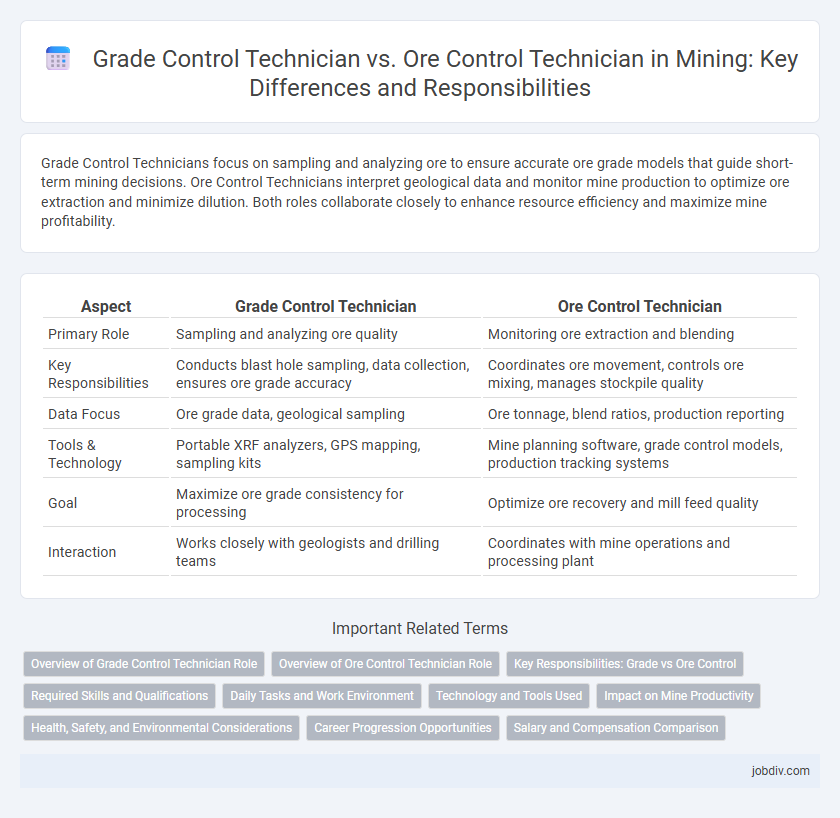

Grade Control Technicians focus on sampling and analyzing ore to ensure accurate ore grade models that guide short-term mining decisions. Ore Control Technicians interpret geological data and monitor mine production to optimize ore extraction and minimize dilution. Both roles collaborate closely to enhance resource efficiency and maximize mine profitability.

Table of Comparison

| Aspect | Grade Control Technician | Ore Control Technician |

|---|---|---|

| Primary Role | Sampling and analyzing ore quality | Monitoring ore extraction and blending |

| Key Responsibilities | Conducts blast hole sampling, data collection, ensures ore grade accuracy | Coordinates ore movement, controls ore mixing, manages stockpile quality |

| Data Focus | Ore grade data, geological sampling | Ore tonnage, blend ratios, production reporting |

| Tools & Technology | Portable XRF analyzers, GPS mapping, sampling kits | Mine planning software, grade control models, production tracking systems |

| Goal | Maximize ore grade consistency for processing | Optimize ore recovery and mill feed quality |

| Interaction | Works closely with geologists and drilling teams | Coordinates with mine operations and processing plant |

Overview of Grade Control Technician Role

Grade Control Technicians are responsible for sampling, mapping, and analyzing ore bodies to ensure accurate grade determination, directly supporting efficient mine planning and production. Their work involves detailed data collection, interpretation of geological information, and communication with mining engineers to optimize ore extraction and minimize dilution. This role is crucial in maintaining ore quality standards and maximizing the economic value of mined resources.

Overview of Ore Control Technician Role

An Ore Control Technician analyzes geological data to ensure precise ore body delineation and optimum resource recovery in mining operations. They collaborate with geologists and engineers to develop grade control models, monitor sampling data, and implement quality assurance processes to maintain ore consistency. Their expertise in ore grade validation directly impacts the economic efficiency and safety of mineral extraction projects.

Key Responsibilities: Grade vs Ore Control

Grade Control Technicians focus on sampling and analyzing mineral content within a mine to ensure the grade meets production specifications, using tools like geochemical assays and blast hole sampling. Ore Control Technicians monitor the placement and movement of ore during extraction, coordinating with mining engineers to optimize ore recovery and minimize dilution by managing the ore-waste boundary. Both roles are critical for maximizing resource efficiency, but Grade Control emphasizes material quality assessment while Ore Control concentrates on the operational management of ore extraction processes.

Required Skills and Qualifications

Grade Control Technicians require strong analytical skills, proficiency in geology software, and experience with mine surveying techniques to accurately assess ore grade variations and ensure efficient mining operations. Ore Control Technicians must possess expertise in geostatistics, sampling methods, and metallurgical testing, alongside the ability to interpret assay data and collaborate with mining engineers to optimize ore extraction processes. Both roles demand a background in mining engineering or geology, excellent problem-solving abilities, and familiarity with health and safety regulations in mining environments.

Daily Tasks and Work Environment

Grade Control Technicians analyze drill hole samples and map ore body boundaries to ensure mining accuracy, working primarily on-site with field equipment and software tools. Ore Control Technicians focus on evaluating ore quality through data collection, data interpretation, and communication with mining engineers, often balancing office-based data analysis with periodic site visits. Both roles require precision and collaboration within dynamic underground or open-pit mining environments to optimize extraction efficiency.

Technology and Tools Used

Grade Control Technicians primarily utilize advanced geospatial software, such as Surpac and Vulcan, to analyze drill data and create detailed ore boundary models for precise mining planning. Ore Control Technicians leverage real-time blast monitoring systems, 3D ore body modeling tools, and automated data integration platforms to validate ore grades and ensure compliance with designed mining parameters. Both roles depend on GPS technology, assay databases, and digital mapping tools to optimize resource extraction and maintain operational efficiency.

Impact on Mine Productivity

Grade Control Technicians play a vital role in enhancing mine productivity by accurately sampling and mapping ore zones, ensuring high-quality material is extracted and minimizing dilution during mining. Ore Control Technicians focus on detailed ore body modeling and real-time data analysis, directly influencing the precision of mining operations and optimizing resource recovery rates. Both positions contribute to maximizing operational efficiency, but Grade Control Technicians emphasize ore quality management, while Ore Control Technicians drive strategic resource scheduling and extraction accuracy.

Health, Safety, and Environmental Considerations

Grade Control Technicians and Ore Control Technicians both play critical roles in mining operations, with distinct responsibilities that impact health, safety, and environmental outcomes. Grade Control Technicians focus on sampling and analyzing ore grades to ensure precise extraction, directly reducing environmental impact by minimizing waste and optimizing resource use. Ore Control Technicians oversee ore quality and operational parameters, implementing safety protocols to prevent hazardous exposure and ensuring compliance with environmental regulations for sustainable mining practices.

Career Progression Opportunities

Grade Control Technicians typically start with sampling and data collection responsibilities, progressing to supervisory roles in quality assurance and mine planning analysis. Ore Control Technicians often advance by integrating geological data with mine operations, leading to positions in resource estimation and strategic orebody modeling. Career progression in both roles emphasizes increasing technical expertise, decision-making authority, and contribution to optimized mine productivity.

Salary and Compensation Comparison

Grade Control Technicians typically earn an average salary ranging from $60,000 to $80,000 annually, focusing on near-mine sampling and analysis to ensure ore quality. Ore Control Technicians generally command higher compensation, with salaries between $75,000 and $95,000 per year, reflecting their responsibility for optimizing ore extraction and blending strategies. Variations in pay are influenced by location, experience, and the complexity of mining operations, with Ore Control roles often incorporating bonuses linked to production efficiency.

Grade Control Technician vs Ore Control Technician Infographic

jobdiv.com

jobdiv.com