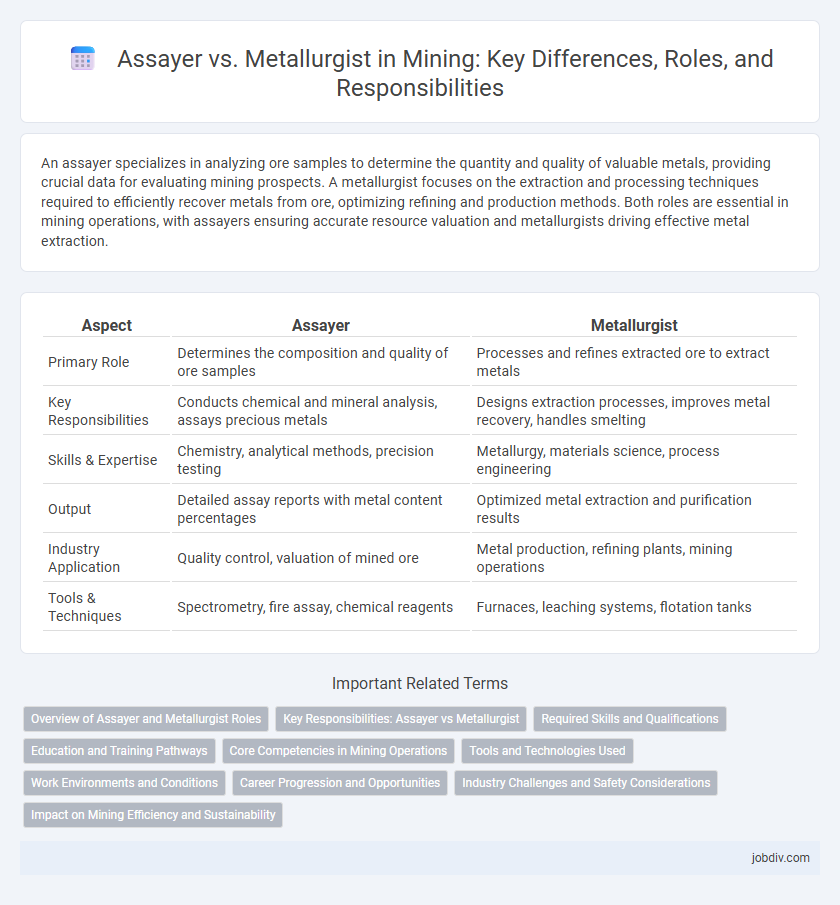

An assayer specializes in analyzing ore samples to determine the quantity and quality of valuable metals, providing crucial data for evaluating mining prospects. A metallurgist focuses on the extraction and processing techniques required to efficiently recover metals from ore, optimizing refining and production methods. Both roles are essential in mining operations, with assayers ensuring accurate resource valuation and metallurgists driving effective metal extraction.

Table of Comparison

| Aspect | Assayer | Metallurgist |

|---|---|---|

| Primary Role | Determines the composition and quality of ore samples | Processes and refines extracted ore to extract metals |

| Key Responsibilities | Conducts chemical and mineral analysis, assays precious metals | Designs extraction processes, improves metal recovery, handles smelting |

| Skills & Expertise | Chemistry, analytical methods, precision testing | Metallurgy, materials science, process engineering |

| Output | Detailed assay reports with metal content percentages | Optimized metal extraction and purification results |

| Industry Application | Quality control, valuation of mined ore | Metal production, refining plants, mining operations |

| Tools & Techniques | Spectrometry, fire assay, chemical reagents | Furnaces, leaching systems, flotation tanks |

Overview of Assayer and Metallurgist Roles

Assayers analyze ore samples to determine the content and quality of valuable metals, providing critical data for mining operations and ore valuation. Metallurgists apply this data to develop and optimize extraction processes, improving metal recovery and refining techniques. Both roles are essential in ensuring efficient resource utilization and maximizing economic returns in mining projects.

Key Responsibilities: Assayer vs Metallurgist

Assayers are responsible for analyzing ore samples to determine the precise metal content, ensuring accurate assay results through chemical and instrumental techniques. Metallurgists focus on developing and optimizing extraction and refining processes to maximize metal recovery and improve operational efficiency. Both roles collaborate closely, with assayers providing critical data that informs metallurgical process adjustments and quality control.

Required Skills and Qualifications

Assayers require strong analytical chemistry skills, proficiency in laboratory techniques, and certification in assaying methods to accurately evaluate ore samples for mineral content. Metallurgists must have expertise in materials science, process engineering, and metallurgy, often holding a degree in metallurgical or mining engineering for designing and optimizing extraction processes. Both roles demand attention to detail, problem-solving abilities, and experience with industry-standard testing equipment to ensure efficient resource recovery.

Education and Training Pathways

Assayers typically pursue education in chemistry or geology, often obtaining a bachelor's degree with specialized training in mineral analysis and laboratory techniques. Metallurgists usually follow an educational pathway in materials science or metallurgical engineering, focusing on extracting and refining metals through advanced coursework and practical internships. Both professions require hands-on experience, but assayers emphasize analytical precision while metallurgists concentrate on process optimization and material properties.

Core Competencies in Mining Operations

Assayers specialize in the precise chemical analysis of ore samples, ensuring accurate measurement of metal content critical for valuation and extraction decisions in mining operations. Metallurgists focus on optimizing the processing methods to extract and refine metals efficiently, applying expertise in physical and chemical properties to improve recovery rates and reduce costs. Both roles are essential, with assayers providing critical data for resource estimation and metallurgists driving process innovation and operational efficiency.

Tools and Technologies Used

Assayers employ precision instruments such as atomic absorption spectrometers and X-ray fluorescence analyzers to determine the composition and purity of ore samples. Metallurgists utilize advanced tools like ball mills, furnaces, and extraction equipment to process raw materials into refined metals. Both professionals rely on computer-aided design (CAD) software and laboratory information management systems (LIMS) to analyze data and optimize mining operations.

Work Environments and Conditions

Assayers typically work in laboratories where they conduct chemical analyses of ore samples under controlled conditions using precise instruments. Metallurgists operate both in laboratories and on-site at mining or processing facilities, managing the extraction and refining processes often in environments exposed to heat, dust, and heavy machinery. While assayers require meticulous attention to detail in sterile settings, metallurgists must adapt to dynamic, sometimes harsh industrial conditions to optimize metal recovery.

Career Progression and Opportunities

Assayers typically begin their careers analyzing ore samples to determine metal content, providing essential data for mining operations, which can lead to advancement into senior assayer roles or quality control management. Metallurgists focus on processing and refining extracted ores, often progressing from laboratory technicians to senior metallurgists and eventually managerial positions overseeing plant operations or research and development. Both career paths offer opportunities to specialize in areas such as mineral extraction, process optimization, or environmental compliance, with potential to move into consulting or executive roles within the mining industry.

Industry Challenges and Safety Considerations

Assayers and metallurgists face distinct industry challenges, with assayers needing precise chemical analysis amid sample heterogeneity, while metallurgists address the complexities of extraction processes and material recovery efficiency. Safety considerations are paramount, as assayers handle potentially hazardous chemicals requiring strict laboratory protocols, whereas metallurgists work in high-temperature, heavy machinery environments necessitating rigorous industrial safety standards. Both roles demand continuous adaptation to evolving environmental regulations and technological advancements to minimize occupational risks and ensure sustainable mining operations.

Impact on Mining Efficiency and Sustainability

Assayers ensure precise mineral content analysis, directly influencing ore valuation and extraction strategies to maximize profitability and minimize waste. Metallurgists develop advanced processing techniques that enhance metal recovery rates and reduce environmental impact through energy-efficient and sustainable practices. Collaboration between assayers and metallurgists drives innovation in mining efficiency and sustainability by aligning accurate resource assessment with optimized metallurgical processes.

Assayer vs Metallurgist Infographic

jobdiv.com

jobdiv.com