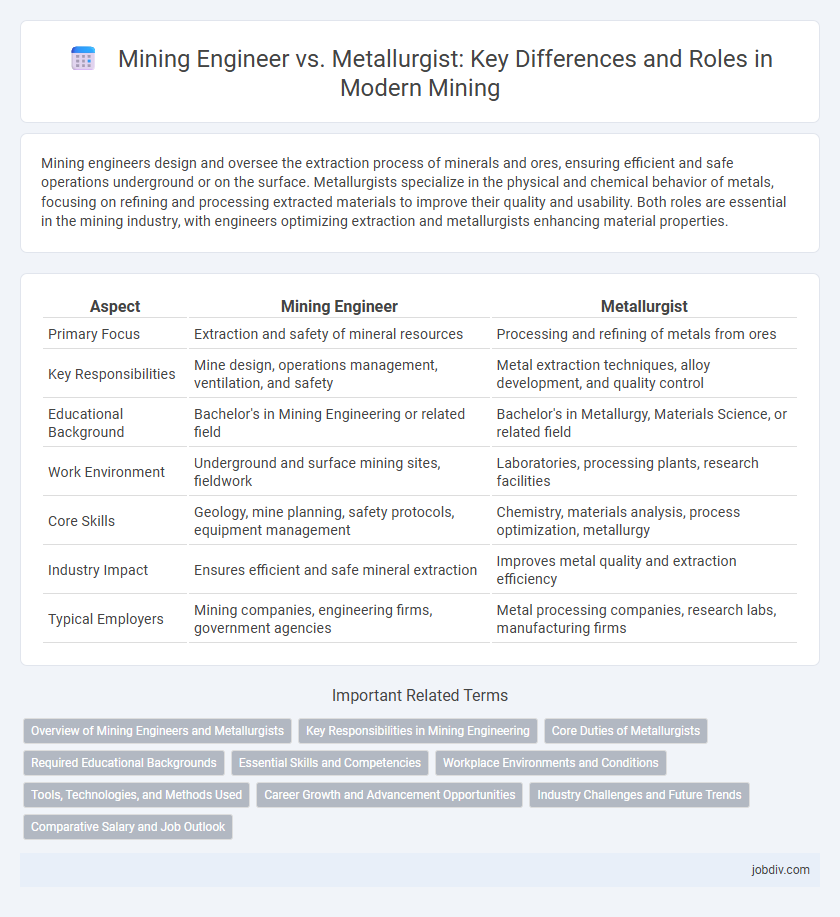

Mining engineers design and oversee the extraction process of minerals and ores, ensuring efficient and safe operations underground or on the surface. Metallurgists specialize in the physical and chemical behavior of metals, focusing on refining and processing extracted materials to improve their quality and usability. Both roles are essential in the mining industry, with engineers optimizing extraction and metallurgists enhancing material properties.

Table of Comparison

| Aspect | Mining Engineer | Metallurgist |

|---|---|---|

| Primary Focus | Extraction and safety of mineral resources | Processing and refining of metals from ores |

| Key Responsibilities | Mine design, operations management, ventilation, and safety | Metal extraction techniques, alloy development, and quality control |

| Educational Background | Bachelor's in Mining Engineering or related field | Bachelor's in Metallurgy, Materials Science, or related field |

| Work Environment | Underground and surface mining sites, fieldwork | Laboratories, processing plants, research facilities |

| Core Skills | Geology, mine planning, safety protocols, equipment management | Chemistry, materials analysis, process optimization, metallurgy |

| Industry Impact | Ensures efficient and safe mineral extraction | Improves metal quality and extraction efficiency |

| Typical Employers | Mining companies, engineering firms, government agencies | Metal processing companies, research labs, manufacturing firms |

Overview of Mining Engineers and Metallurgists

Mining engineers design and oversee the extraction process of minerals from the earth, ensuring efficient site development and resource maximization. Metallurgists specialize in analyzing and improving the physical and chemical properties of metals extracted during mining, focusing on refining and material performance. Both roles collaborate to optimize resource recovery and enhance the economic value of mined materials.

Key Responsibilities in Mining Engineering

Mining engineers design and develop efficient methods for extracting minerals from the earth, focusing on mine planning, safety protocols, and optimizing production processes. They assess geological data to determine the best mining techniques and oversee the installation of equipment and infrastructure to ensure sustainable and cost-effective operations. Their responsibilities also include managing environmental impact, adhering to regulatory compliance, and coordinating cross-functional teams to maintain operational efficiency.

Core Duties of Metallurgists

Metallurgists specialize in analyzing and improving the physical and chemical properties of metals to optimize extraction and processing techniques in mining operations. Their core duties include conducting material testing, developing refining processes, and ensuring metal quality and durability through advanced metallurgical methods. They collaborate closely with mining engineers to enhance ore recovery rates and minimize environmental impact during extraction.

Required Educational Backgrounds

Mining engineers typically require a bachelor's degree in mining engineering or a closely related field, emphasizing courses in geology, mineral extraction, and mine design. Metallurgists usually hold degrees in metallurgical or materials engineering, focusing on physical and chemical properties of metals and processes like alloy development and refinement. Both professions often pursue specialized certifications or advanced degrees to enhance expertise in resource extraction and metal processing.

Essential Skills and Competencies

Mining engineers excel in skills such as mine design, ventilation systems, and mineral extraction techniques, focusing on optimizing safety and operational efficiency. Metallurgists specialize in materials science, demonstrating competencies in ore processing, metal extraction, and quality control to enhance metal properties and recovery rates. Both roles require strong analytical abilities, problem-solving expertise, and knowledge of industry-specific software and regulations.

Workplace Environments and Conditions

Mining engineers typically work onsite at mining operations where conditions can be physically demanding and require strict adherence to safety protocols in rugged outdoor environments. Metallurgists often operate in laboratory or plant settings, focusing on metal extraction and processing under controlled, industrial conditions that may involve exposure to chemicals and high temperatures. Both professions demand specialized knowledge, but mining engineers encounter more variable and harsh field environments compared to the more stable, technical workplaces of metallurgists.

Tools, Technologies, and Methods Used

Mining engineers utilize advanced tools such as 3D geological modeling software, automated drilling rigs, and real-time data analytics platforms to design efficient and safe mining operations. Metallurgists employ techniques including pyrometallurgy, hydrometallurgy, and extractive metallurgy, leveraging laboratory instruments like spectrometers and electron microscopes to optimize metal extraction and processing. Both professionals integrate cutting-edge technologies like machine learning and process simulation software to enhance resource recovery and operational sustainability.

Career Growth and Advancement Opportunities

Mining Engineers typically experience rapid career growth through roles in project management, operations, and safety oversight, leveraging skills in mine design and resource extraction. Metallurgists advance by specializing in material properties, extraction processes, and quality control, often moving into research and development or plant management positions. Both career paths offer strong advancement opportunities, with Mining Engineers focusing on site leadership and Metallurgists on improving metallurgical processes and product innovation.

Industry Challenges and Future Trends

Mining engineers and metallurgists face distinct industry challenges; mining engineers tackle resource extraction optimization and environmental impact reduction, while metallurgists focus on improving ore processing efficiency and material recovery rates. Both disciplines must address future trends such as automation integration, sustainable practices, and adapting to fluctuating commodity markets driven by global demand. Advances in AI-driven data analytics and green technologies are pivotal for enhancing operational efficiency and reducing the mining sector's carbon footprint.

Comparative Salary and Job Outlook

Mining engineers typically earn a median annual salary of around $93,000, while metallurgists average slightly higher at approximately $97,000, reflecting their specialized expertise in materials science. Job outlook for mining engineers shows a steady demand driven by infrastructure and energy projects, projected to grow about 3% over the next decade, whereas metallurgists face a faster growth rate of roughly 5% due to advancements in recycling and material innovation. Both careers require strong technical skills but metallurgists often benefit from broader opportunities in diverse industries beyond traditional mining operations.

Mining Engineer vs Metallurgist Infographic

jobdiv.com

jobdiv.com