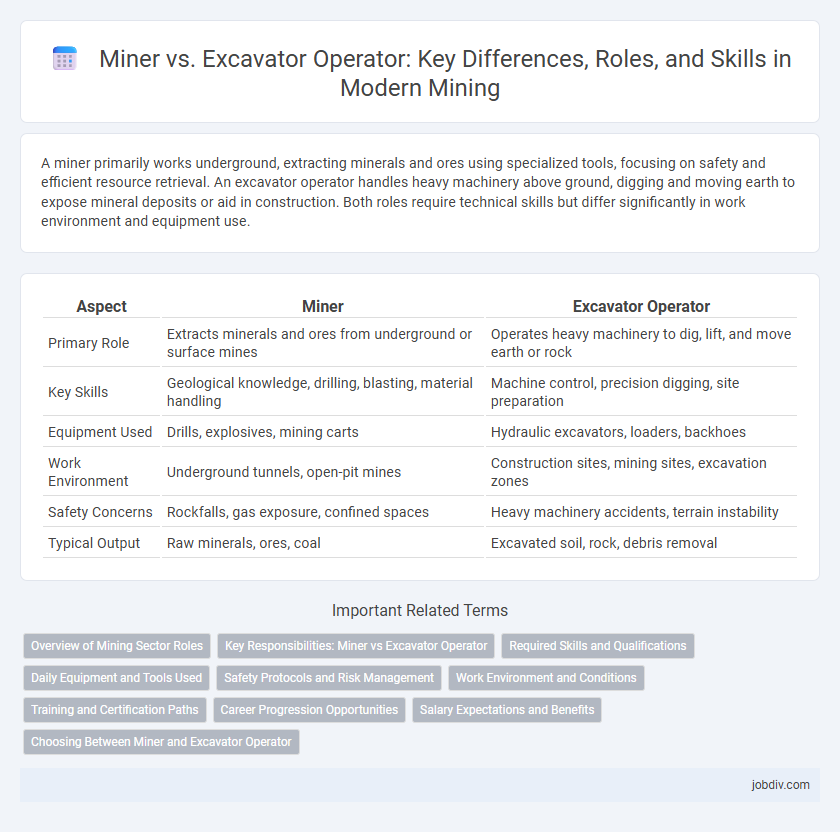

A miner primarily works underground, extracting minerals and ores using specialized tools, focusing on safety and efficient resource retrieval. An excavator operator handles heavy machinery above ground, digging and moving earth to expose mineral deposits or aid in construction. Both roles require technical skills but differ significantly in work environment and equipment use.

Table of Comparison

| Aspect | Miner | Excavator Operator |

|---|---|---|

| Primary Role | Extracts minerals and ores from underground or surface mines | Operates heavy machinery to dig, lift, and move earth or rock |

| Key Skills | Geological knowledge, drilling, blasting, material handling | Machine control, precision digging, site preparation |

| Equipment Used | Drills, explosives, mining carts | Hydraulic excavators, loaders, backhoes |

| Work Environment | Underground tunnels, open-pit mines | Construction sites, mining sites, excavation zones |

| Safety Concerns | Rockfalls, gas exposure, confined spaces | Heavy machinery accidents, terrain instability |

| Typical Output | Raw minerals, ores, coal | Excavated soil, rock, debris removal |

Overview of Mining Sector Roles

Miner roles primarily focus on extracting raw minerals and ores through manual or mechanized methods, emphasizing hands-on underground or surface mining activities. Excavator operators specialize in maneuvering heavy machinery to dig, load, and transport earth and minerals, playing a crucial role in site preparation and material handling. Both positions are essential in the mining sector, contributing to efficient resource extraction and operational safety.

Key Responsibilities: Miner vs Excavator Operator

Miners are responsible for extracting minerals and ores from underground or surface mines using specialized tools and equipment, ensuring safety and compliance with mining regulations. Excavator operators control heavy machinery to dig, move, and load earth materials, facilitating access to mining sites and removing overburden effectively. Both roles require precision and adherence to operational protocols, with miners focusing on extraction and operators managing excavation and material handling tasks.

Required Skills and Qualifications

Miner positions demand proficiency in operating drilling and blasting equipment, with strong knowledge of mineral extraction processes and safety regulations. Excavator operators must demonstrate expert handling of heavy machinery, spatial awareness, and hydraulic system maintenance skills. Both roles require physical stamina, attention to detail, and adherence to occupational health and safety standards in mining environments.

Daily Equipment and Tools Used

Miner operators primarily utilize drills, blasting tools, and loading machines such as continuous miners and shuttle cars to extract materials efficiently. Excavator operators rely heavily on hydraulic excavators, buckets, and grapples for digging, earthmoving, and loading operations on mining sites. Both roles require proficiency with safety gear, GPS systems, and maintenance tools to ensure optimal equipment performance and worker safety.

Safety Protocols and Risk Management

Miner and excavator operators implement rigorous safety protocols to mitigate risks associated with underground and surface mining activities. Both roles require adherence to hazard assessment procedures, proper use of personal protective equipment (PPE), and routine equipment inspections to prevent accidents such as cave-ins, equipment collisions, and exposure to harmful substances. Effective communication and emergency response training are essential components in risk management strategies to ensure a safe working environment in mining operations.

Work Environment and Conditions

Miner roles typically involve working underground in confined, dark spaces with higher exposure to dust, noise, and hazardous gases, requiring extensive use of personal protective equipment. Excavator operators generally work on surface mining sites where they face variable weather conditions, noise, and vibrations from heavy machinery but enjoy better ventilation and more open environments. Both positions demand physical stamina and attention to safety protocols, yet the miner's environment poses greater risks related to collapse and air quality.

Training and Certification Paths

Miner training typically emphasizes underground safety protocols, equipment handling, and mineral extraction techniques, requiring certifications like MSHA Part 46 or 48 for compliance. Excavator operators pursue specialized training on heavy machinery operation, focusing on maneuvering, site-specific hazards, and standard OSHA certification courses such as the NCCCO for crane and heavy equipment operation. Both roles demand continuous skill upgrades and safety training to meet rigorous industry standards and regulatory requirements.

Career Progression Opportunities

Miner positions often serve as entry-level roles in the mining industry, providing foundational experience in underground or surface extraction techniques. Excavator operators typically require advanced training and certification, positioning them for higher-responsibility tasks involving large-scale equipment and site management. Career progression often leads from miner to excavator operator, with opportunities to advance into supervisory or specialist roles in equipment operation and mine planning.

Salary Expectations and Benefits

Miner salaries typically range from $45,000 to $75,000 annually, with benefits such as health insurance, retirement plans, and hazard pay often included. Excavator operators usually earn between $50,000 and $85,000 per year, benefiting from similar perks along with opportunities for overtime pay and skill-based bonuses. Both roles offer competitive compensation packages, but excavator operators may have higher earning potential due to the technical expertise required.

Choosing Between Miner and Excavator Operator

Choosing between a miner and an excavator operator depends on the specific requirements of the mining project, such as the type of material to be extracted and the scale of operation. Miner roles emphasize underground extraction techniques and knowledge of drilling and blasting, while excavator operators focus on surface-level digging and material handling with heavy machinery. Understanding the operational environment and project goals is essential for selecting the right equipment operator to optimize productivity and safety.

Miner vs Excavator Operator Infographic

jobdiv.com

jobdiv.com