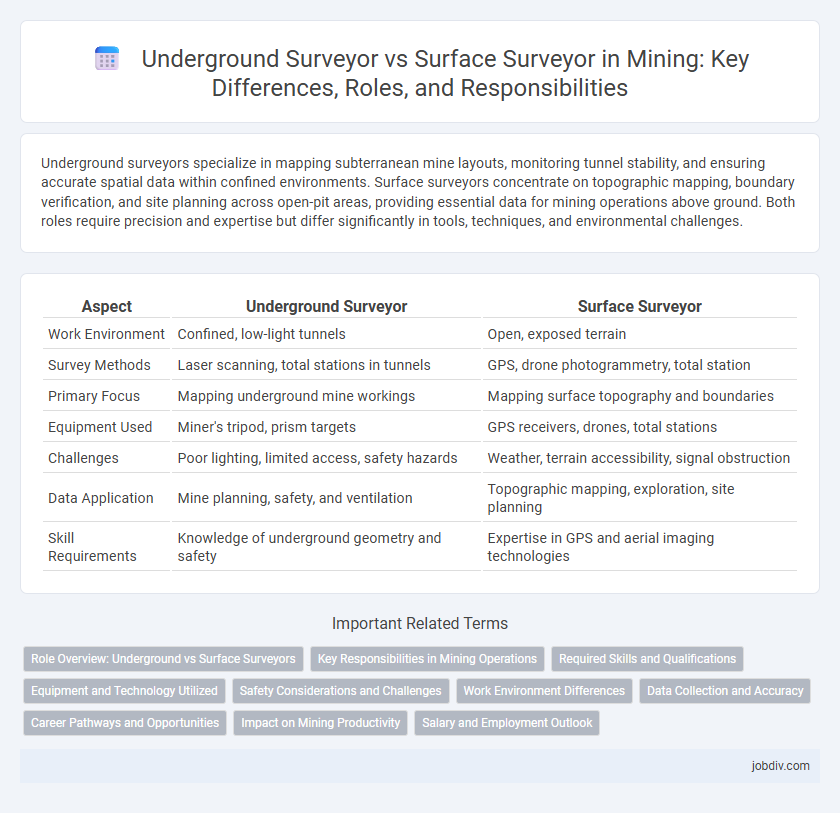

Underground surveyors specialize in mapping subterranean mine layouts, monitoring tunnel stability, and ensuring accurate spatial data within confined environments. Surface surveyors concentrate on topographic mapping, boundary verification, and site planning across open-pit areas, providing essential data for mining operations above ground. Both roles require precision and expertise but differ significantly in tools, techniques, and environmental challenges.

Table of Comparison

| Aspect | Underground Surveyor | Surface Surveyor |

|---|---|---|

| Work Environment | Confined, low-light tunnels | Open, exposed terrain |

| Survey Methods | Laser scanning, total stations in tunnels | GPS, drone photogrammetry, total station |

| Primary Focus | Mapping underground mine workings | Mapping surface topography and boundaries |

| Equipment Used | Miner's tripod, prism targets | GPS receivers, drones, total stations |

| Challenges | Poor lighting, limited access, safety hazards | Weather, terrain accessibility, signal obstruction |

| Data Application | Mine planning, safety, and ventilation | Topographic mapping, exploration, site planning |

| Skill Requirements | Knowledge of underground geometry and safety | Expertise in GPS and aerial imaging technologies |

Role Overview: Underground vs Surface Surveyors

Underground surveyors specialize in mapping subterranean mine structures, ensuring tunnel alignment, and monitoring geological stability to guide safe excavation processes. Surface surveyors focus on establishing accurate topographical data, managing land boundaries, and supporting open-pit mining operations through precise surface measurements. Both roles are crucial for comprehensive mine planning, with underground surveyors addressing underground spatial challenges and surface surveyors handling external mine site data.

Key Responsibilities in Mining Operations

Underground surveyors specialize in mapping and measuring subterranean mine layouts, ensuring accurate tunnel alignment and monitoring ground stability to support safe excavation processes. Surface surveyors handle topographic measurements, boundary determinations, and provide essential geospatial data for mine planning, equipment positioning, and land reclamation efforts. Both roles require precise data collection and analysis to optimize mining operations and maintain regulatory compliance.

Required Skills and Qualifications

Underground surveyors require expertise in spatial data collection within confined and often hazardous environments, necessitating proficiency in tunnel mapping, laser scanning, and use of specialized equipment like total stations adapted for subterranean conditions. Surface surveyors must excel in topographic mapping, GPS technology, and geodetic calculations, with strong skills in managing safety protocols for open-pit environments and exposure to varying weather conditions. Both roles demand a background in geomatics, civil engineering, or surveying technology, along with certifications such as Professional Land Surveyor (PLS) and proficiency in CAD software for precise data analysis and plotting.

Equipment and Technology Utilized

Underground surveyors utilize specialized technologies such as laser scanners, total stations with coaxial long-range capabilities, and gyroscopic stations designed for confined and GPS-denied environments in mine tunnels. Surface surveyors rely heavily on GPS technology, drones equipped with LiDAR, and robotic total stations to capture precise topographic data over expansive and open mining areas. Both roles require advanced data processing software, but underground surveyors depend on equipment optimized for spatial constraints and low visibility while surface surveyors leverage wide-area geospatial mapping tools.

Safety Considerations and Challenges

Underground surveyors face heightened safety risks such as limited ventilation, poor lighting, and potential exposure to hazardous gases, requiring specialized training and equipment to navigate confined spaces safely. In contrast, surface surveyors contend with environmental hazards like extreme weather conditions and rugged terrain, but generally benefit from better access to emergency services. Both roles demand rigorous safety protocols, yet underground surveying challenges are intensified by the mine's structural instability and the need for continuous atmospheric monitoring.

Work Environment Differences

Underground surveyors operate in confined, low-light conditions with limited ventilation and elevated safety risks such as gas exposure and rock falls. Surface surveyors work in open environments exposed to weather variations, ranging from extreme heat to cold, with fewer physical hazards but increased reliance on GPS technology. The contrasting work environments significantly influence the surveying methods and equipment used by each professional.

Data Collection and Accuracy

Underground surveyors utilize highly precise laser scanning and gyrotheodolite instruments to collect spatial data in constrained, low-light environments, ensuring accurate mapping of complex subterranean structures. Surface surveyors rely on GPS and total station technology to gather topographic data over large, open areas, providing broad-scale positional accuracy critical for mine planning. Both roles emphasize data integrity but differ in methods due to environmental challenges affecting measurement precision.

Career Pathways and Opportunities

Underground surveyors specialize in mapping and measuring subterranean mine layouts, providing critical data for safe and efficient excavation, which leads to career opportunities in mine design, safety inspection, and resource management. Surface surveyors focus on topographical mapping, land boundary determination, and environmental monitoring, often advancing into roles in geospatial analysis, project management, and environmental compliance. Both career paths demand expertise in surveying technology and offer progression into managerial or consulting positions within the mining industry.

Impact on Mining Productivity

Underground surveyors enhance mining productivity by providing precise spatial data critical for pit design, tunnel alignment, and resource estimation, enabling safer and more efficient extraction processes. Surface surveyors contribute by mapping terrain and monitoring ground movement, which supports mine planning and infrastructure stability, preventing costly disruptions. Integration of underground and surface survey data optimizes resource allocation and operational decision-making, leading to increased overall mining productivity.

Salary and Employment Outlook

Underground surveyors in mining typically earn higher salaries than surface surveyors due to the increased risks and specialized skills required for subterranean environments, with average salaries ranging from $70,000 to $100,000 annually. Employment prospects for underground surveyors are growing steadily, driven by expansion in deep mining operations and technological advancements in geospatial mapping. Surface surveyors see consistent demand as surface mining and land reclamation projects continue, with median salaries between $55,000 and $75,000 and steady job growth aligned with infrastructure development.

Underground Surveyor vs Surface Surveyor Infographic

jobdiv.com

jobdiv.com