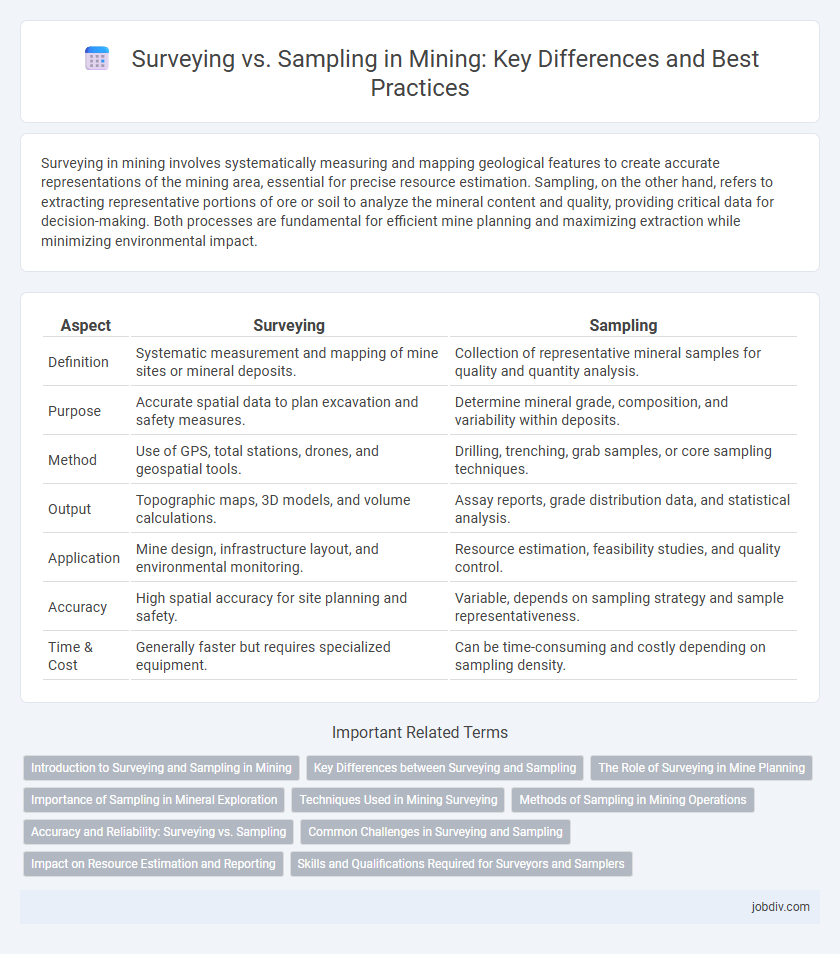

Surveying in mining involves systematically measuring and mapping geological features to create accurate representations of the mining area, essential for precise resource estimation. Sampling, on the other hand, refers to extracting representative portions of ore or soil to analyze the mineral content and quality, providing critical data for decision-making. Both processes are fundamental for efficient mine planning and maximizing extraction while minimizing environmental impact.

Table of Comparison

| Aspect | Surveying | Sampling |

|---|---|---|

| Definition | Systematic measurement and mapping of mine sites or mineral deposits. | Collection of representative mineral samples for quality and quantity analysis. |

| Purpose | Accurate spatial data to plan excavation and safety measures. | Determine mineral grade, composition, and variability within deposits. |

| Method | Use of GPS, total stations, drones, and geospatial tools. | Drilling, trenching, grab samples, or core sampling techniques. |

| Output | Topographic maps, 3D models, and volume calculations. | Assay reports, grade distribution data, and statistical analysis. |

| Application | Mine design, infrastructure layout, and environmental monitoring. | Resource estimation, feasibility studies, and quality control. |

| Accuracy | High spatial accuracy for site planning and safety. | Variable, depends on sampling strategy and sample representativeness. |

| Time & Cost | Generally faster but requires specialized equipment. | Can be time-consuming and costly depending on sampling density. |

Introduction to Surveying and Sampling in Mining

Surveying in mining involves precise measurement and mapping of mineral deposits to determine their location, size, and shape, using techniques like GPS, total stations, and laser scanning. Sampling focuses on collecting representative portions of ore or soil to analyze mineral content and quality, employing methods such as core drilling, trenching, and grab sampling. Combining surveying and sampling enhances resource estimation accuracy and supports effective mine planning and operational decisions.

Key Differences between Surveying and Sampling

Surveying in mining involves systematic data collection over a defined area to create detailed maps and models of mineral deposits, emphasizing spatial accuracy and geological context. Sampling extracts representative material subsets from ore bodies to analyze composition and grade, focusing on statistical reliability and mineral quantification. Key differences lie in surveying's broad spatial assessment versus sampling's targeted material evaluation for resource estimation.

The Role of Surveying in Mine Planning

Surveying plays a critical role in mine planning by providing accurate spatial data and mapping of the mining site, enabling precise resource estimation and effective design of excavation sequences. It ensures the alignment of mine infrastructure with geological formations, optimizing extraction processes and minimizing operational risks. Surveying data integrates with geological models to guide decision-making and enhance the efficiency and safety of mining operations.

Importance of Sampling in Mineral Exploration

Sampling plays a crucial role in mineral exploration by providing representative data on mineral content and distribution, which guides informed decision-making and resource estimation. Unlike surveying, which maps surface features and terrain, sampling directly assesses the quality and quantity of mineral deposits through systematic collection and analysis of ore or soil samples. Accurate sampling techniques reduce risks and costs by identifying economically viable zones and enabling targeted drilling programs in mining projects.

Techniques Used in Mining Surveying

Mining surveying employs techniques such as total stations, GPS, and laser scanning to create accurate maps and models of underground and surface mining sites. These methods enable precise measurement of terrain, excavation volumes, and ore body boundaries, essential for effective resource extraction and operational safety. In contrast, sampling focuses on collecting and analyzing ore samples to determine grade and composition, rather than spatial positioning.

Methods of Sampling in Mining Operations

Sampling methods in mining operations include grab sampling, channel sampling, and bulk sampling, each providing critical data for resource estimation and grade control. Grab sampling collects surface material at a single point for preliminary analysis, while channel sampling involves cutting a continuous strip across a rock face to obtain a representative sample of the mineralized zone. Bulk sampling extracts larger volumes of ore to assess grade variability and processing characteristics, ensuring accurate evaluation of ore deposits.

Accuracy and Reliability: Surveying vs. Sampling

Surveying in mining delivers high accuracy by providing precise geospatial data that maps the ore body's exact boundaries and volume. Sampling, while faster and cost-effective, offers variable reliability depending on sample size and representativeness, potentially leading to estimation errors. Optimizing mining operations requires integrating detailed surveying with statistically sound sampling methods to balance accuracy and efficiency.

Common Challenges in Surveying and Sampling

Common challenges in mining surveying include dealing with uneven terrain, ensuring precise measurement accuracy, and managing data integration from multiple sources. In sampling, difficulties arise in obtaining representative samples due to geological variability, sample contamination, and maintaining consistency during collection. Both processes require stringent quality control to minimize errors that can significantly impact mineral resource estimation and project feasibility.

Impact on Resource Estimation and Reporting

Surveying provides precise spatial data critical for accurate resource estimation by defining deposit boundaries and volumes, which enhances the reliability of geological models. Sampling directly influences the quality of grade estimation and variability assessment, affecting confidence levels in resource classification and reporting. Integrating high-quality surveying data with representative sampling results leads to more robust resource estimations and compliance with industry reporting standards such as JORC or NI 43-101.

Skills and Qualifications Required for Surveyors and Samplers

Surveyors in mining require expertise in geospatial measurement techniques, proficiency with GPS and GIS technology, and strong analytical skills to accurately map and assess mineral deposits. Sampling specialists must possess knowledge of soil and rock sampling methods, attention to detail for representative data collection, and familiarity with laboratory testing protocols to ensure sample integrity. Both roles demand a solid foundation in geology or mining engineering, alongside certifications such as Certified Mine Surveyor for surveyors and training in sampling standards for samplers.

Surveying vs Sampling Infographic

jobdiv.com

jobdiv.com