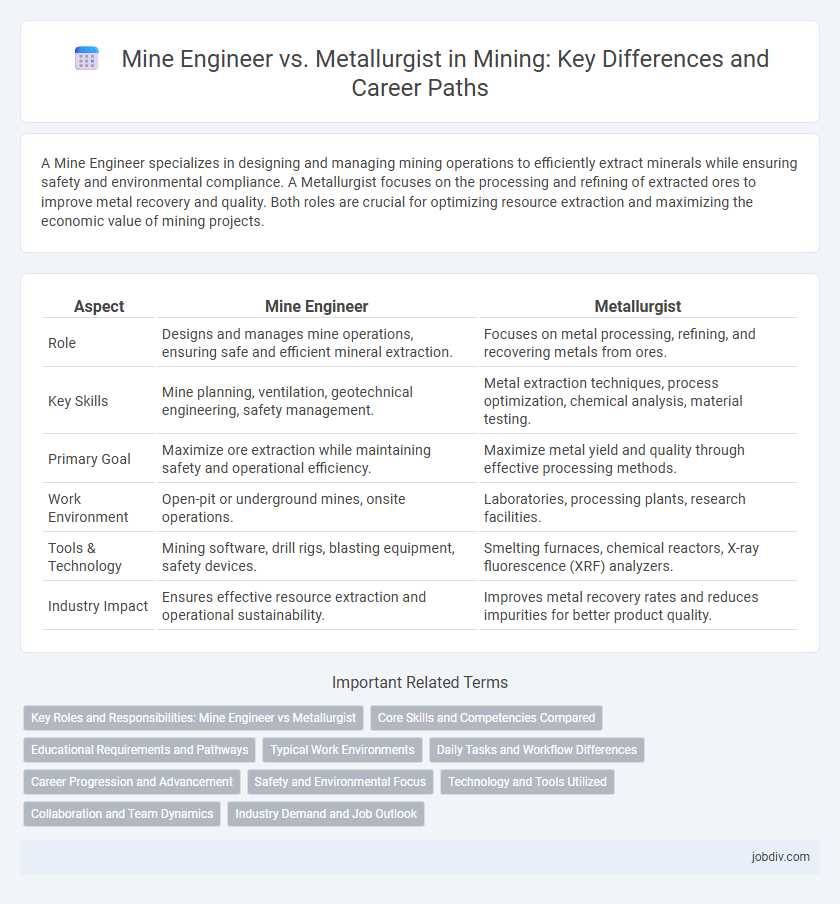

A Mine Engineer specializes in designing and managing mining operations to efficiently extract minerals while ensuring safety and environmental compliance. A Metallurgist focuses on the processing and refining of extracted ores to improve metal recovery and quality. Both roles are crucial for optimizing resource extraction and maximizing the economic value of mining projects.

Table of Comparison

| Aspect | Mine Engineer | Metallurgist |

|---|---|---|

| Role | Designs and manages mine operations, ensuring safe and efficient mineral extraction. | Focuses on metal processing, refining, and recovering metals from ores. |

| Key Skills | Mine planning, ventilation, geotechnical engineering, safety management. | Metal extraction techniques, process optimization, chemical analysis, material testing. |

| Primary Goal | Maximize ore extraction while maintaining safety and operational efficiency. | Maximize metal yield and quality through effective processing methods. |

| Work Environment | Open-pit or underground mines, onsite operations. | Laboratories, processing plants, research facilities. |

| Tools & Technology | Mining software, drill rigs, blasting equipment, safety devices. | Smelting furnaces, chemical reactors, X-ray fluorescence (XRF) analyzers. |

| Industry Impact | Ensures effective resource extraction and operational sustainability. | Improves metal recovery rates and reduces impurities for better product quality. |

Key Roles and Responsibilities: Mine Engineer vs Metallurgist

Mine engineers focus on planning, designing, and supervising mining operations to efficiently extract minerals while ensuring safety and environmental compliance. Metallurgists specialize in analyzing and processing extracted ores to optimize metal recovery, refining techniques, and improving material quality. Both roles collaborate to enhance overall mining productivity and resource utilization through technical expertise and process innovation.

Core Skills and Competencies Compared

Mine engineers excel in geological survey interpretation, drilling techniques, and mine design, ensuring efficient extraction processes and safety protocols. Metallurgists specialize in material science, focusing on ore processing, metallurgical testing, and refining methods to optimize metal recovery and quality. Both roles require strong analytical skills and knowledge of mining technology, but mine engineers prioritize operational planning while metallurgists emphasize chemical and physical transformation of extracted materials.

Educational Requirements and Pathways

Mine engineers typically pursue a Bachelor's degree in Mining Engineering, focusing on subjects like geology, mineral extraction, and mine safety, with many advancing through internships and professional certifications such as the Professional Engineer (PE) license. Metallurgists generally require a Bachelor's degree in Metallurgical or Materials Engineering, specializing in the physical and chemical behavior of metals, with pathways often including laboratory research, process optimization training, and certifications like the Society for Mining, Metallurgy & Exploration (SME) credentials. Both careers emphasize strong foundations in math and science but differ in their technical focus and industry-specific skill development.

Typical Work Environments

Mine engineers primarily operate on-site at mining locations, managing infrastructure development, drilling, and extraction processes in open-pit or underground mines. Metallurgists typically work in laboratories, processing plants, or research facilities where they analyze ore samples, oversee metal recovery methods, and optimize refining techniques. Both roles require collaboration but differ fundamentally in their work settings, with mine engineers focused on field operations and metallurgists on material testing and process efficiency.

Daily Tasks and Workflow Differences

Mine engineers oversee underground and surface operations, focusing on mine design, safety protocols, and extraction efficiency to optimize resource recovery. Metallurgists analyze ore samples, develop processing techniques, and monitor metallurgical operations to improve metal extraction and refine product quality. While mine engineers coordinate excavation and logistics, metallurgists concentrate on chemical and physical ore transformations within processing plants.

Career Progression and Advancement

Mine engineers advance by gaining expertise in mine design, safety protocols, and resource management, often progressing to roles like mine manager or operations director. Metallurgists focus on improving extraction methods, refining processes, and material quality control, with career paths leading to chief metallurgist or process engineering manager. Both disciplines offer growth through technical specialization and leadership positions within mining operations and resource development.

Safety and Environmental Focus

Mine engineers prioritize the structural integrity and stability of mine operations to ensure worker safety and prevent environmental hazards such as collapses and contaminant leaks. Metallurgists focus on processing and refining metals with techniques that minimize toxic emissions and waste, optimizing environmental sustainability alongside safety protocols. Both roles collaborate to implement safety standards and environmental regulations, reducing risks associated with mining activities.

Technology and Tools Utilized

Mine engineers utilize advanced drilling and blasting software, geological modeling tools, and automated machinery for efficient extraction and site management. Metallurgists rely on sophisticated laboratory instruments like spectrometers, X-ray fluorescence analyzers, and process control software to analyze ore composition and optimize metal recovery techniques. Both professionals integrate emerging technologies such as data analytics and remote sensing to enhance operational precision and resource management.

Collaboration and Team Dynamics

Mine engineers and metallurgists collaborate closely to optimize mineral extraction and processing efficiency. Effective team dynamics are essential as mine engineers design and oversee excavation operations, while metallurgists focus on refining mineral properties and improving metal recovery. Their integrated efforts ensure seamless transition from raw ore extraction to processing, maximizing yield and cost-effectiveness in mining projects.

Industry Demand and Job Outlook

Mine Engineers specialize in designing and supervising mining operations, with a strong demand driven by the global increase in mineral extraction projects, especially in copper, gold, and lithium sectors. Metallurgists focus on extracting and processing metals, facing growing opportunities due to advancements in sustainable metal recovery and recycling technologies. The job outlook for both roles remains positive, but mine engineers typically have broader employment prospects in field operations, while metallurgists are increasingly sought after in refining, environmental compliance, and materials innovation.

Mine Engineer vs Metallurgist Infographic

jobdiv.com

jobdiv.com