Production planners in mining oversee the broader coordination of resource allocation, ensuring that production targets align with corporate goals and overall operational efficiency. Mine schedulers focus on creating detailed, short-term schedules for the extraction process, optimizing daily equipment use and labor deployment to maximize output. Both roles require precise data analysis and collaboration to balance strategic planning with tactical execution in mining operations.

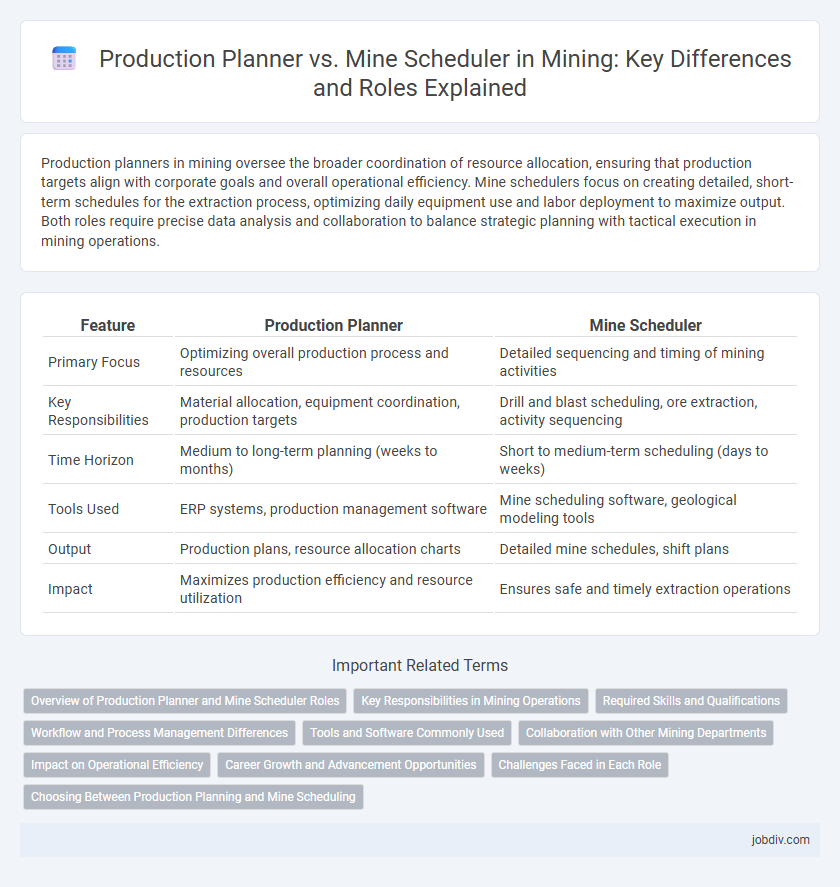

Table of Comparison

| Feature | Production Planner | Mine Scheduler |

|---|---|---|

| Primary Focus | Optimizing overall production process and resources | Detailed sequencing and timing of mining activities |

| Key Responsibilities | Material allocation, equipment coordination, production targets | Drill and blast scheduling, ore extraction, activity sequencing |

| Time Horizon | Medium to long-term planning (weeks to months) | Short to medium-term scheduling (days to weeks) |

| Tools Used | ERP systems, production management software | Mine scheduling software, geological modeling tools |

| Output | Production plans, resource allocation charts | Detailed mine schedules, shift plans |

| Impact | Maximizes production efficiency and resource utilization | Ensures safe and timely extraction operations |

Overview of Production Planner and Mine Scheduler Roles

Production planners in mining coordinate resource allocation and workflow to ensure efficient extraction and material handling, optimizing plant operations and minimizing downtime. Mine schedulers develop detailed timetables for mining activities, balancing operational constraints with equipment availability to maximize ore recovery and meet production targets. Both roles collaborate closely to synchronize planning and scheduling, enhancing overall mine productivity and operational efficiency.

Key Responsibilities in Mining Operations

Production planners in mining operations are responsible for coordinating resources, materials, and manpower to ensure efficient production flow and meet output targets. Mine schedulers focus on creating detailed, time-based schedules for extraction activities, optimizing the sequence and timing of mining equipment and workforce deployment. Both roles collaborate to balance operational efficiency, safety protocols, and cost management within mining projects.

Required Skills and Qualifications

Production Planners in mining require strong analytical skills, expertise in supply chain management, and proficiency in software like ERP and production planning tools to optimize resource allocation. Mine Schedulers need in-depth knowledge of mining operations, expertise in scheduling software such as MineSched or Deswik, and the ability to interpret geological data for effective timeline management. Both roles demand a solid understanding of mining industry regulations, safety standards, and excellent communication skills to coordinate multidisciplinary teams.

Workflow and Process Management Differences

Production Planners focus on aligning mining output with market demand by strategizing resource allocation, long-term production targets, and cost efficiency through integrated planning systems. Mine Schedulers specialize in detailed short-term scheduling of mining activities, optimizing drilling, blasting, and hauling sequences based on geological data and equipment availability to maximize operational productivity. The workflow differentiation lies in Production Planners managing overarching production timelines, while Mine Schedulers handle granular, day-to-day task coordination within those timelines.

Tools and Software Commonly Used

Production planners in mining typically utilize enterprise resource planning (ERP) software like SAP and Microsoft Dynamics to coordinate materials, labor, and equipment across multiple projects. Mine schedulers rely heavily on specialized software such as Datamine, Surpac, and Vulcan to create detailed short-term and long-term mine schedules based on geological data and production targets. Both roles leverage GPS tracking systems and real-time monitoring tools like Hexagon Mining's hardware solutions to optimize operational efficiency and ensure alignment with production goals.

Collaboration with Other Mining Departments

Production planners collaborate closely with geological, engineering, and equipment maintenance teams to ensure resource availability and operational efficiency. Mine schedulers work hand-in-hand with production planners and safety officers to develop detailed schedules that optimize extraction while adhering to safety and regulatory standards. Effective communication and data sharing between these roles enhance decision-making and improve overall mining project outcomes.

Impact on Operational Efficiency

Production planners optimize resource allocation and workflow to maximize output while minimizing costs, directly influencing operational efficiency in mining projects. Mine schedulers develop detailed excavation sequences and timelines, ensuring that mining activities align with production targets and equipment availability. Their coordinated efforts reduce downtime, streamline operations, and increase overall productivity in mining operations.

Career Growth and Advancement Opportunities

Production planners in mining often have broader responsibilities overseeing entire production processes, which positions them for leadership roles in operations management and strategic planning. Mine schedulers specialize in creating detailed extraction schedules, gaining expertise valuable for advanced technical roles or transitioning into mine planning engineering. Both career paths offer growth, but production planners generally experience faster advancement due to their holistic involvement in production efficiency and resource allocation.

Challenges Faced in Each Role

Production Planners often face challenges in aligning resource availability with fluctuating market demands while ensuring cost-effective operations and meeting safety regulations. Mine Schedulers encounter difficulties in optimizing drilling and blasting sequences, managing equipment utilization, and adapting schedules to geological uncertainties and unexpected operational delays. Both roles require balancing efficiency with regulatory compliance and adapting to dynamic environmental and logistical constraints in mining projects.

Choosing Between Production Planning and Mine Scheduling

Choosing between production planning and mine scheduling requires evaluating operational goals and resource allocation efficiency. Production planners focus on long-term strategies, optimizing material flow and equipment utilization to meet overall output targets. Mine schedulers prioritize short-term task sequencing and shift-level assignments, ensuring daily activities align with the mine plan and adapt to changing conditions.

Production Planner vs Mine Scheduler Infographic

jobdiv.com

jobdiv.com