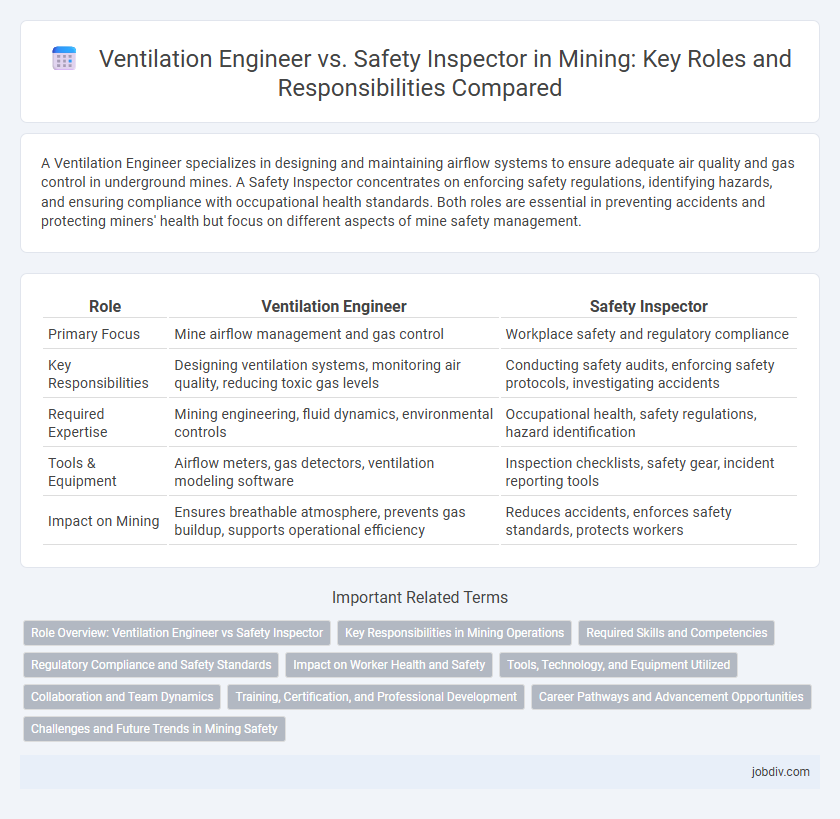

A Ventilation Engineer specializes in designing and maintaining airflow systems to ensure adequate air quality and gas control in underground mines. A Safety Inspector concentrates on enforcing safety regulations, identifying hazards, and ensuring compliance with occupational health standards. Both roles are essential in preventing accidents and protecting miners' health but focus on different aspects of mine safety management.

Table of Comparison

| Role | Ventilation Engineer | Safety Inspector |

|---|---|---|

| Primary Focus | Mine airflow management and gas control | Workplace safety and regulatory compliance |

| Key Responsibilities | Designing ventilation systems, monitoring air quality, reducing toxic gas levels | Conducting safety audits, enforcing safety protocols, investigating accidents |

| Required Expertise | Mining engineering, fluid dynamics, environmental controls | Occupational health, safety regulations, hazard identification |

| Tools & Equipment | Airflow meters, gas detectors, ventilation modeling software | Inspection checklists, safety gear, incident reporting tools |

| Impact on Mining | Ensures breathable atmosphere, prevents gas buildup, supports operational efficiency | Reduces accidents, enforces safety standards, protects workers |

Role Overview: Ventilation Engineer vs Safety Inspector

A Ventilation Engineer in mining specializes in designing and maintaining airflow systems to ensure a safe and breathable underground environment, focusing on controlling hazardous gases and temperature. A Safety Inspector concentrates on enforcing safety regulations, conducting risk assessments, and ensuring compliance with mining safety standards to prevent accidents. Both roles are critical for maintaining operational safety but differ in technical focus and regulatory enforcement.

Key Responsibilities in Mining Operations

Ventilation Engineers design and maintain air flow systems to ensure proper ventilation, reduce hazardous gases, and control temperature in underground mines. Safety Inspectors conduct regular inspections, enforce compliance with safety regulations, and identify potential hazards to prevent accidents and ensure worker safety. Both roles are critical for operational safety, with Ventilation Engineers focusing on air quality and environmental control, while Safety Inspectors emphasize regulatory adherence and risk mitigation.

Required Skills and Competencies

Ventilation Engineers in mining require expertise in airflow design, gas monitoring systems, and regulatory compliance to maintain safe underground environments. Safety Inspectors must possess strong knowledge of hazard identification, risk assessment, and emergency response protocols to enforce mining safety standards effectively. Both roles demand analytical skills, attention to detail, and thorough understanding of mining regulations to minimize workplace accidents.

Regulatory Compliance and Safety Standards

Ventilation engineers design and maintain mine airflow systems to meet regulatory compliance with standards set by agencies such as MSHA and OSHA, ensuring hazardous gases and dust levels remain within permissible exposure limits. Safety inspectors conduct audits and inspections to verify that all ventilation controls and other safety equipment adhere to federal and state regulations, identifying non-compliance issues that could lead to citations or shutdowns. Both roles are critical for upholding safety standards, reducing health risks, and preventing accidents in underground mining operations.

Impact on Worker Health and Safety

Ventilation engineers design and maintain airflow systems to control hazardous gases and dust, significantly reducing risks of respiratory diseases and explosions in mining environments. Safety inspectors enforce compliance with safety regulations, conduct hazard assessments, and ensure protective measures are implemented to prevent accidents and injuries. Both roles collaboratively enhance worker health and safety by minimizing exposure to harmful conditions and promoting a secure mining operation.

Tools, Technology, and Equipment Utilized

Ventilation Engineers utilize advanced airflow modeling software, gas detection systems, and automated ventilation controls to optimize underground mine air quality and ensure continuous airflow. Safety Inspectors rely on portable gas analyzers, personal protective equipment (PPE), and compliance auditing tools to identify hazards and enforce safety regulations in mining environments. Both roles integrate real-time monitoring devices and communication technologies, but Ventilation Engineers focus more on environmental control systems, while Safety Inspectors emphasize hazard detection and regulatory adherence.

Collaboration and Team Dynamics

Ventilation engineers and safety inspectors collaborate closely to optimize mine safety by ensuring proper airflow and mitigating hazardous conditions such as gas buildup and dust accumulation. Their teamwork integrates technical expertise in mine ventilation systems with regulatory compliance and hazard identification, enabling proactive risk management. Effective communication and coordinated efforts between these professionals enhance overall mine safety culture and operational efficiency.

Training, Certification, and Professional Development

Ventilation Engineers in mining undergo specialized training in airflow management, gas detection, and environmental control, often requiring certifications such as the Certified Ventilation Professional (CVP). Safety Inspectors receive comprehensive education on hazard recognition, regulatory compliance, and emergency response, commonly obtaining certifications like the Certified Safety Professional (CSP). Both roles emphasize continuous professional development through workshops, industry seminars, and updated certifications to maintain expertise in mining safety and operational efficiency.

Career Pathways and Advancement Opportunities

Ventilation engineers in mining specialize in designing and managing airflow systems to ensure safe underground environments, with career advancement opportunities leading to senior engineering roles or ventilation consultancy. Safety inspectors focus on regulatory compliance, hazard identification, and enforcement of safety standards, often advancing into supervisory or safety management positions within mining operations. Both career paths offer progression through additional certifications and experience, with ventilation engineers typically pursuing technical expertise, while safety inspectors emphasize regulatory knowledge and risk management skills.

Challenges and Future Trends in Mining Safety

Ventilation engineers face challenges in designing efficient airflow systems that control toxic gases and maintain breathable air in deep mining environments, while safety inspectors focus on regulatory compliance and hazard identification to prevent accidents. Emerging technologies like real-time air quality monitoring, AI-driven predictive maintenance, and automated ventilation adjustments are transforming mining safety protocols. Future trends emphasize integrated safety solutions combining engineering expertise with advanced data analytics to enhance risk management and ensure worker health and safety.

Ventilation Engineer vs Safety Inspector Infographic

jobdiv.com

jobdiv.com