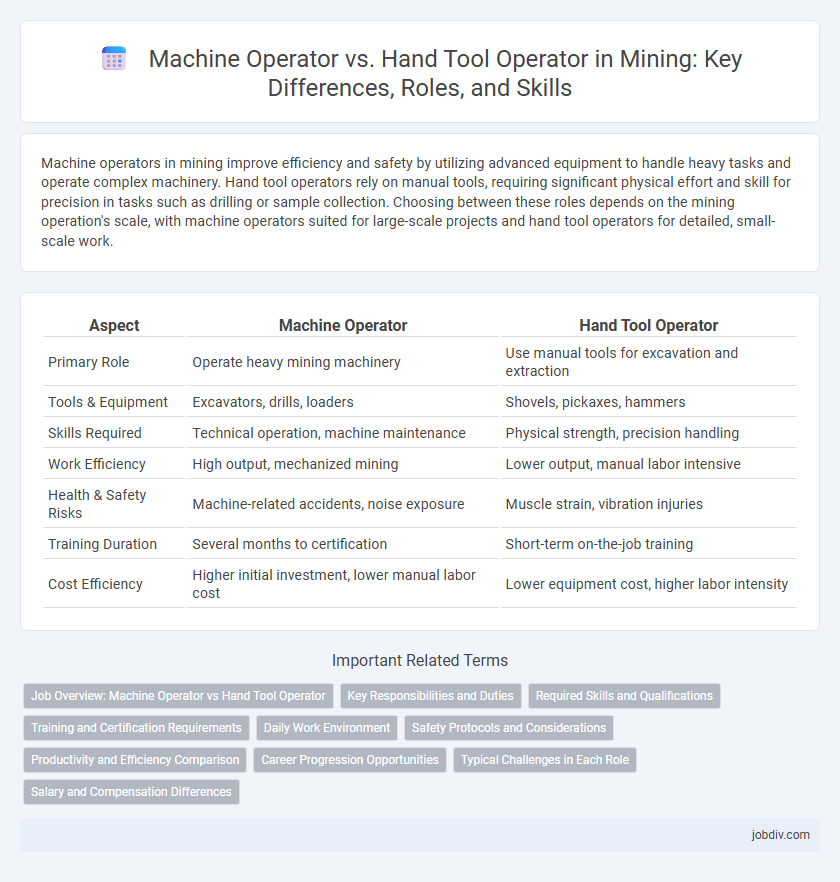

Machine operators in mining improve efficiency and safety by utilizing advanced equipment to handle heavy tasks and operate complex machinery. Hand tool operators rely on manual tools, requiring significant physical effort and skill for precision in tasks such as drilling or sample collection. Choosing between these roles depends on the mining operation's scale, with machine operators suited for large-scale projects and hand tool operators for detailed, small-scale work.

Table of Comparison

| Aspect | Machine Operator | Hand Tool Operator |

|---|---|---|

| Primary Role | Operate heavy mining machinery | Use manual tools for excavation and extraction |

| Tools & Equipment | Excavators, drills, loaders | Shovels, pickaxes, hammers |

| Skills Required | Technical operation, machine maintenance | Physical strength, precision handling |

| Work Efficiency | High output, mechanized mining | Lower output, manual labor intensive |

| Health & Safety Risks | Machine-related accidents, noise exposure | Muscle strain, vibration injuries |

| Training Duration | Several months to certification | Short-term on-the-job training |

| Cost Efficiency | Higher initial investment, lower manual labor cost | Lower equipment cost, higher labor intensity |

Job Overview: Machine Operator vs Hand Tool Operator

Machine Operators in mining control heavy machinery such as excavators, drills, and conveyor systems to extract and transport minerals efficiently, requiring technical skills and safety compliance. Hand Tool Operators perform manual tasks using handheld tools like pickaxes, shovels, and pneumatic drills, focusing on precise, physical labor often in confined or delicate areas. Both roles demand strong adherence to safety protocols, but Machine Operators typically handle automated processes while Hand Tool Operators provide essential support in detailed, hands-on excavation work.

Key Responsibilities and Duties

Machine operators in mining oversee the operation and maintenance of heavy equipment such as excavators, loaders, and trucks, ensuring efficient extraction and transportation of minerals. Hand tool operators focus on manual tasks, using specialized tools for drilling, cutting, and breaking rock or ore to assist in site preparation and mineral processing. Both roles require adherence to safety protocols and precision to maintain productivity and prevent workplace accidents.

Required Skills and Qualifications

Machine Operators in mining require technical proficiency with heavy equipment, knowledge of safety protocols, and the ability to interpret machinery diagnostics. Hand Tool Operators need manual dexterity, precision, and experience with specialized hand tools used for drilling, measuring, and sample collection. Both roles demand physical stamina and adherence to strict safety standards, but Machine Operators typically require formal training or certification in operating complex machinery.

Training and Certification Requirements

Machine operators in mining require formal training programs and certifications such as MSHA (Mine Safety and Health Administration) compliance, demonstrating proficiency in handling heavy machinery and safety protocols. Hand tool operators typically undergo shorter, skill-specific training sessions emphasizing manual dexterity and hazard recognition but may also need basic safety certifications relevant to mining environments. Both roles necessitate ongoing certification renewals to adhere to evolving safety standards and operational regulations within the mining industry.

Daily Work Environment

Machine operators in mining work in mechanized environments, handling heavy equipment like excavators and drills, often within noisy, dusty conditions requiring protective gear. Hand tool operators perform physically intensive tasks using manual tools such as hammers and shovels, typically in confined or less mechanized areas with direct exposure to mineral surfaces and debris. Both roles demand adherence to strict safety protocols but differ significantly in ergonomic challenges and equipment complexity during daily operations.

Safety Protocols and Considerations

Machine operators in mining must follow rigorous safety protocols such as continuous equipment inspections, use of personal protective equipment (PPE), and adherence to lockout/tagout procedures to prevent accidents. Hand tool operators prioritize ergonomic techniques and regular hand tool maintenance to minimize strain injuries and tool-related hazards. Both roles require comprehensive safety training tailored to their specific operational risks to ensure a safe working environment.

Productivity and Efficiency Comparison

Machine operators in mining achieve higher productivity and efficiency by leveraging advanced equipment that automates excavation and material handling tasks, reducing manual labor and operational time. Hand tool operators typically experience lower output rates due to physical limitations and increased ergonomic strain, impacting overall efficiency and throughput. Data from mining productivity studies indicate machine operators can increase rock extraction rates by up to 30% compared to hand tool operators while maintaining consistent safety standards.

Career Progression Opportunities

Machine operators in mining benefit from advanced career progression opportunities due to the technical skills required for operating heavy machinery and familiarity with automated systems. Hand tool operators typically face limited upward mobility, often moving to supervisory roles or specialized manual tasks without significant increases in responsibility. The mining industry increasingly values machine operators who can adapt to evolving technology, positioning them for higher-paying and more stable career paths.

Typical Challenges in Each Role

Machine operators in mining face challenges such as equipment malfunctions, maintaining safety protocols amid heavy machinery, and managing complex technology interfaces for efficient operation. Hand tool operators encounter physical strain, precision demands in confined spaces, and increased risk of injury due to manual handling of tools and unstable environments. Both roles require rigorous attention to safety standards but differ in the nature of operational risks and skill sets needed for optimal performance.

Salary and Compensation Differences

Machine operators in mining typically earn higher salaries compared to hand tool operators, reflecting the technical skills required to manage heavy machinery and automated equipment. Average annual wages for machine operators range from $45,000 to $75,000, while hand tool operators generally earn between $30,000 and $50,000. Compensation packages for machine operators often include performance bonuses, hazard pay, and comprehensive benefits, enhancing their overall earnings beyond base salary.

Machine Operator vs Hand Tool Operator Infographic

jobdiv.com

jobdiv.com