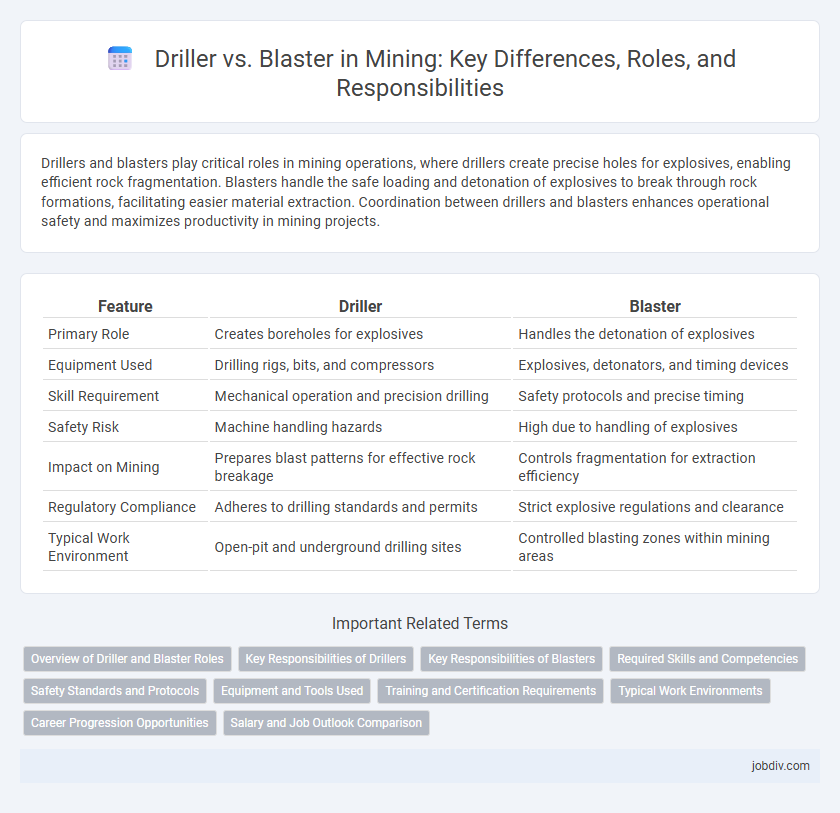

Drillers and blasters play critical roles in mining operations, where drillers create precise holes for explosives, enabling efficient rock fragmentation. Blasters handle the safe loading and detonation of explosives to break through rock formations, facilitating easier material extraction. Coordination between drillers and blasters enhances operational safety and maximizes productivity in mining projects.

Table of Comparison

| Feature | Driller | Blaster |

|---|---|---|

| Primary Role | Creates boreholes for explosives | Handles the detonation of explosives |

| Equipment Used | Drilling rigs, bits, and compressors | Explosives, detonators, and timing devices |

| Skill Requirement | Mechanical operation and precision drilling | Safety protocols and precise timing |

| Safety Risk | Machine handling hazards | High due to handling of explosives |

| Impact on Mining | Prepares blast patterns for effective rock breakage | Controls fragmentation for extraction efficiency |

| Regulatory Compliance | Adheres to drilling standards and permits | Strict explosive regulations and clearance |

| Typical Work Environment | Open-pit and underground drilling sites | Controlled blasting zones within mining areas |

Overview of Driller and Blaster Roles

Drillers operate heavy machinery to create drill holes for explosives, ensuring precise placement and depth to optimize fragmentation in mining operations. Blasters handle the preparation and controlled detonation of explosives within these drill holes, focusing on safety protocols and blast design to maximize ore recovery and minimize environmental impact. Both roles require specialized training and coordination to maintain efficiency and safety in underground and surface mining environments.

Key Responsibilities of Drillers

Drillers operate and maintain drilling equipment to create holes for blasting or extraction, ensuring precision and safety in the mining process. They monitor drill performance, adjust equipment settings, and manage drill bit replacements to optimize efficiency. Drillers also interpret geological data to determine appropriate drilling techniques, reducing operational risks and supporting overall mining productivity.

Key Responsibilities of Blasters

Blasters in mining are responsible for designing and implementing controlled explosive detonations to fragment rock efficiently while ensuring safety and minimizing environmental impact. They calculate precise explosive quantities, determine blast patterns, and coordinate timing sequences to optimize fragmentation and reduce vibration. Monitoring compliance with safety regulations and training crew members are essential duties to prevent accidents and guarantee operational effectiveness.

Required Skills and Competencies

Drillers require strong technical skills in operating heavy machinery and precise control over drilling equipment to ensure accurate boreholes and minimize environmental impact. Blasters must possess in-depth knowledge of explosives, safety protocols, and regulatory compliance to design effective blast patterns while preventing hazards. Both roles demand keen attention to detail, problem-solving abilities, and adherence to strict safety standards essential for successful mining operations.

Safety Standards and Protocols

Drillers and blasters in mining adhere to stringent safety standards to mitigate risks associated with their specialized tasks. Drillers focus on precise equipment handling and regular maintenance checks to prevent mechanical failures, while blasters follow rigorous protocols for explosive storage, handling, and detonation timing to ensure controlled blasts without incidents. Both roles require comprehensive training, adherence to regulatory frameworks like MSHA (Mine Safety and Health Administration) guidelines, and constant communication to maintain a safe mining environment.

Equipment and Tools Used

Drillers utilize rotary drills, percussion drills, and core barrels to bore precise holes in rock formations, enabling controlled extraction processes. Blasters rely on specialized explosives, detonators, and blasting mats to fragment rock efficiently while ensuring safety and minimizing environmental impact. The choice of equipment directly influences operational efficiency, safety protocols, and overall mining productivity.

Training and Certification Requirements

Drillers typically require certification in equipment operation and safety procedures specific to drilling machinery, including OSHA-compliant training programs and hands-on experience with rotary or percussive drills. Blasters must complete specialized certification in explosives handling, storage, and detonation techniques, often governed by federal and state regulations such as ATF licensing and MSHA training. Both roles demand rigorous adherence to safety protocols, but blasters undergo more extensive training due to the high-risk nature of managing explosives in mining environments.

Typical Work Environments

Drillers typically operate in controlled underground mines or open-pit quarries, where precision and equipment maintenance are crucial for efficient rock breaking. Blasters work in similar mining environments but are more often involved in preparing blast sites, handling explosives, and ensuring safety protocols are strictly followed around hazardous zones. Both roles demand familiarity with rugged terrains and adherence to strict safety regulations to minimize risks associated with heavy machinery and explosive materials.

Career Progression Opportunities

Drillers in mining operations often progress by gaining technical skills in machine operation and maintenance, leading to roles such as Drill Supervisor or Mining Engineer. Blasters specialize in explosives and safety protocols, providing a pathway to positions like Blasting Supervisor or Safety Manager. Both careers offer advancement opportunities through certifications and on-site experience, with blasters typically requiring additional regulatory knowledge for higher roles.

Salary and Job Outlook Comparison

Drillers in mining typically earn an average annual salary ranging from $45,000 to $70,000, depending on experience and location, while blasters often command higher wages between $60,000 and $90,000 due to specialized expertise and certification requirements. The job outlook for drillers shows steady demand driven by ongoing extraction projects, whereas blasters face growing opportunities influenced by stricter safety regulations and increasing use of controlled blasting techniques. Both roles require technical skills and compliance with safety standards, but blasters benefit from a higher earning potential and a slightly more favorable employment forecast in the mining industry.

Driller vs Blaster Infographic

jobdiv.com

jobdiv.com